Manufacturing method of fruit jam using aronia melanocarpa as raw material

A technology of black berry arborum and jam, which is applied in the field of food processing, can solve the problems of poor edibility, etc., and achieve the effects of less nutritional loss, delaying aging, and positive taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

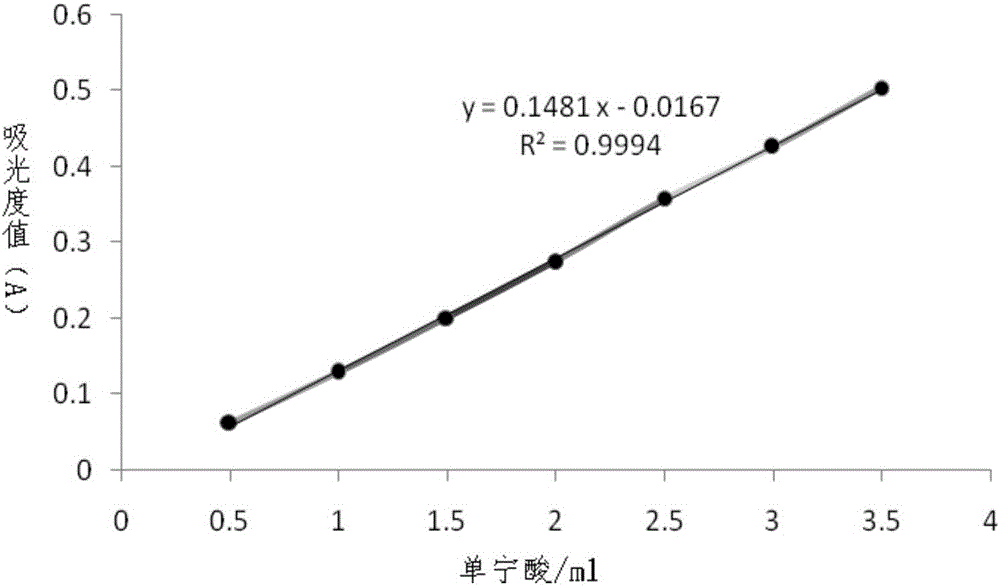

[0047] Preparation of the sample to be tested: Take an appropriate amount of de-astringent Aronia fruit and grind it in a mortar, weigh 3g and add water to 250ml, filter after 1h, discard the initial 10ml filtrate, and take 2ml filtrate to be tested.

[0048] Tannin content is calculated according to the following formula:

[0049] Tannin (mg / g) = p × V 总 ×n / V×W

[0050] In the formula: W is the mass of the Aronia sarana sample, g; V 总 For the total volume of the extract, ml; V is the volume of the extracted extract when colorimetric, ml; p is from the standard curve ( figure 1 ) The tannin (0.1x) contained in the extract obtained by checking, mg.

[0051] In following embodiment, the evaluation standard of jam is shown in the table below:

[0052]

Embodiment 1

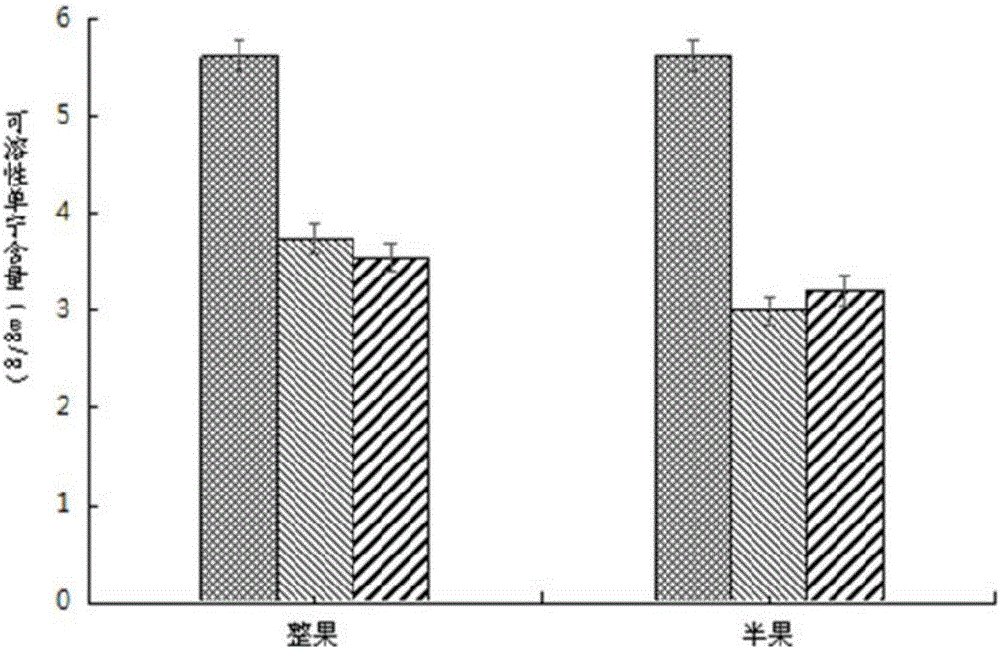

[0054] Example 1: Influence of the state of the fruit of Aronia adenocarpus on the effect of removing astringency

[0055] Half-cut the fruits of Sorbus adenocarpus, and compare the treatment effects with the whole fruits to determine the fruit state required for deastringency. White wine (40%) and fruit vinegar (3%) are used as deastringent agents, both of which are edible and do not affect the jam processing in the later stage. Randomly select four equal parts of mature and complete Aronia sylvestris fruit, two parts are cut in half, and the other two parts keep the fruit intact, and the deastringent agent is taken 50ml respectively (the weight ratio of the fruit and the deastringent agent is 1:10 ), put the prepared fruit samples into the astringent-removing agent respectively, seal them and place them in a constant temperature shaker; treat them at 20°C for 20 minutes, and then take them out to prepare the sample solution to be tested; The effect of the fruit state of Aro...

Embodiment 2

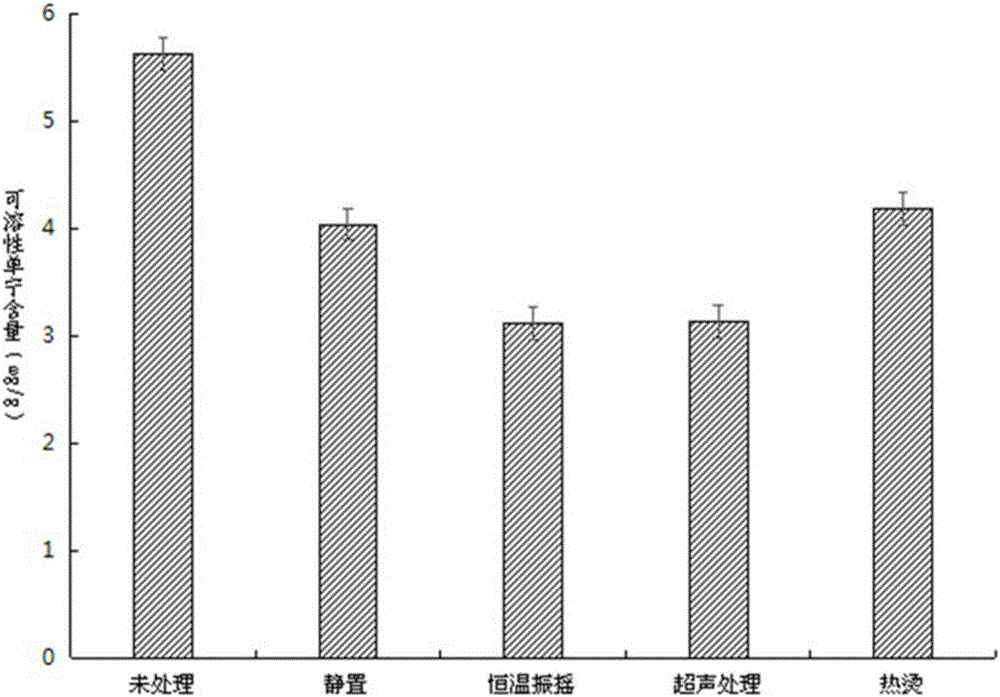

[0057] Example 2: The influence of the way of removing astringent on the effect of removing astringent

[0058] The treatment methods for removing astringency include standing still, blanching, shaking at constant temperature, and ultrasonic treatment. It is 40% astringent removing agent that alcoholic strength is made by adding water that commercially available alcoholic strength is 50% liquor.

[0059] Cut the fruit into half fruit, and evenly divide it into four equal parts, and place each part in white wine with 40% deastringent agent (the weight ratio of fruit and deastringent agent is 1:10); (power 450w), constant temperature shaking treatment method, treatment at 20°C for 20 minutes; blanching method is to put half fruit in boiling water and blanching for 1 minute. A control was set up, and each group was measured three times in parallel. Investigate the effect of deastringent treatment methods on deastringent effect, the results are shown in image 3 :

[0060] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com