Old oil flavor essence and preparation method thereof

A technology of flavor and essence, which is applied in the field of old oil flavor essence and its preparation, can solve the problems affecting the storage and use of essence, strong hygroscopicity, and flavor fading, and achieve good flavor stability, strong aroma and long-lasting fragrance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0036]

[0037]

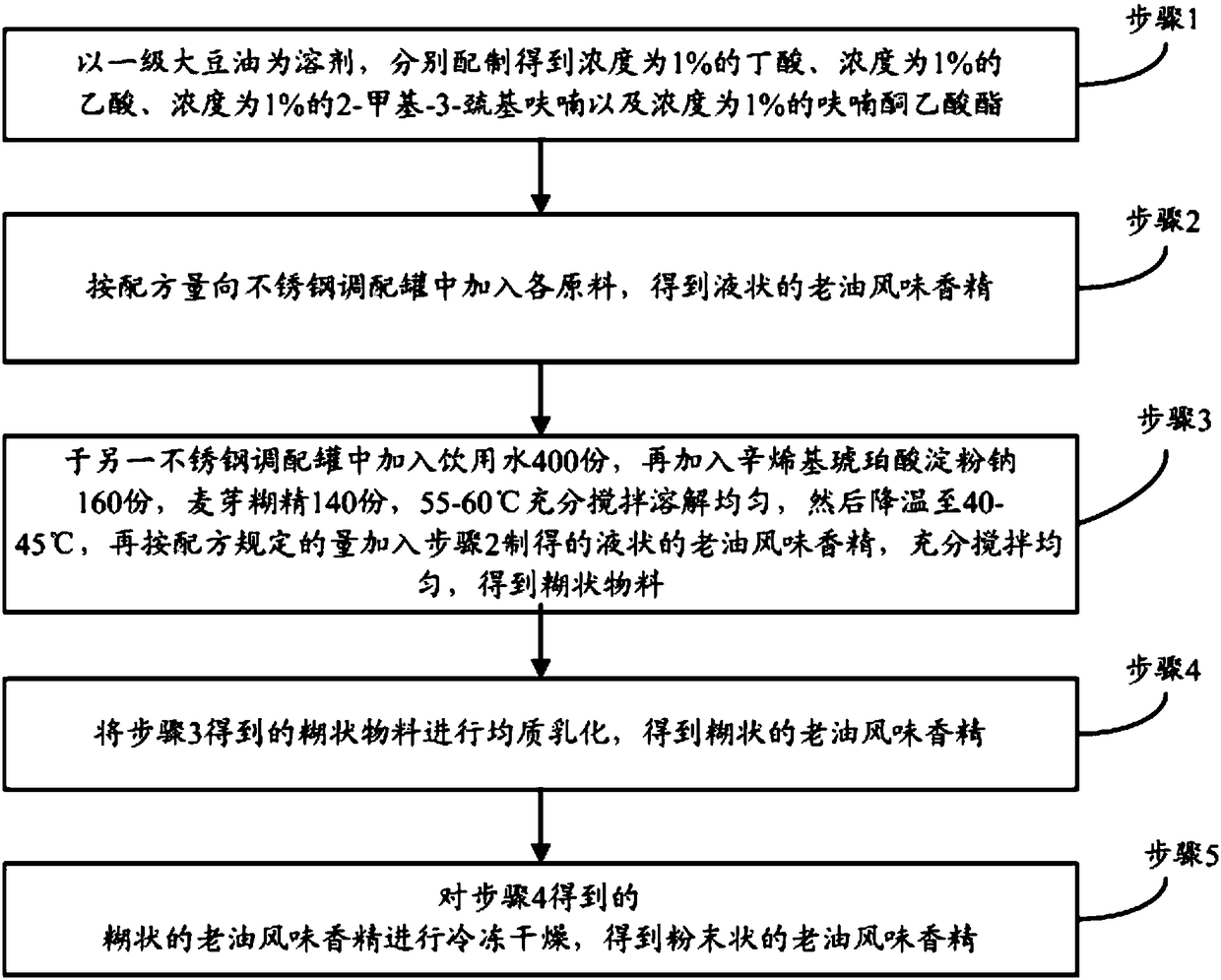

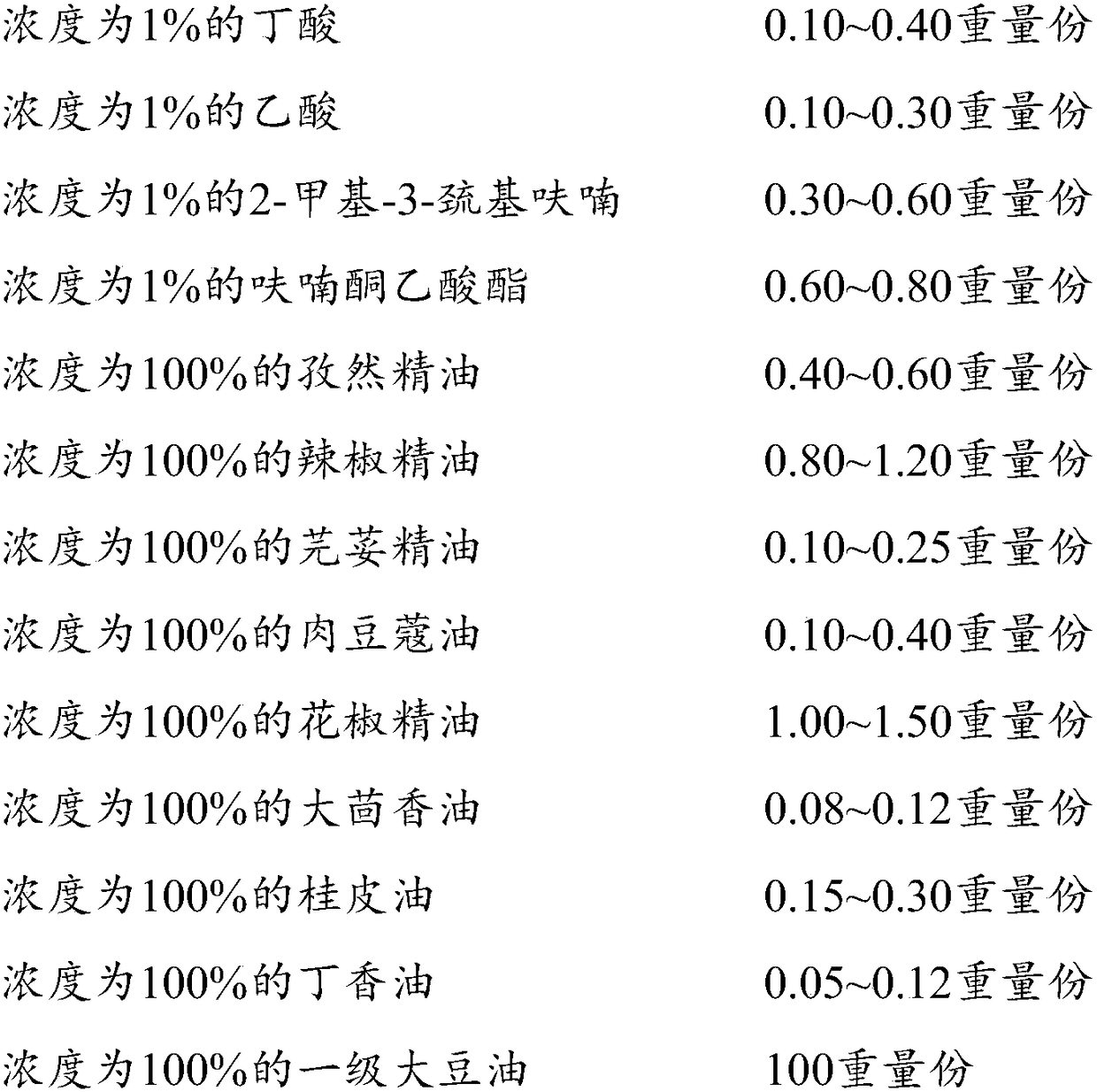

[0038] Step 1, using first-grade soybean oil as a solvent, prepare butyric acid with a concentration of 1%, acetic acid with a concentration of 1%, 2-methyl-3-mercaptofuran with a concentration of 1% and furan with a concentration of 1%. Ketoacetate;

[0039] Step 2, adding concentration is 1% butyric acid, concentration is 1% acetic acid, concentration is 1% 2-methyl-3-mercaptofuran, concentration is 1% furanone B Esters, Cumin essential oil at 100%, Capsicum essential oil at 100%, Coriander essential oil at 100%, Nutmeg oil at 100%, Pepper essential oil at 100%, Pepper essential oil at 100% Anise oil, cinnamon oil with a concentration of 100%, clove oil with a concentration of 100%, and first-grade soybean oil with a concentration of 100% are stirred evenly and passed through a 100-mesh sieve to obtain a liquid old oil flavor essence;

[0040] Step 3: Add 400 parts of drinking water to another stainless steel blending tank, then add 160 parts of sodi...

preparation Embodiment 2

[0049]

[0050] Step 1, using first-grade soybean oil as a solvent, respectively prepare butyric acid with a concentration of 1%, acetic acid with a concentration of 1%, 2-methyl-3-mercaptofuran with a concentration of 1%, and furan with a concentration of 1%. Ketoacetate;

[0051] Step 2, adding concentration is 1% butyric acid, concentration is 1% acetic acid, concentration is 1% 2-methyl-3-mercaptofuran, concentration is 1% furanone B Esters, Cumin essential oil at 100%, Capsicum essential oil at 100%, Coriander essential oil at 100%, Nutmeg oil at 100%, Pepper essential oil at 100%, Pepper essential oil at 100% Anise oil, cinnamon oil with a concentration of 100%, clove oil with a concentration of 100%, and first-grade soybean oil with a concentration of 100% are stirred evenly and passed through a 100-mesh sieve to obtain a liquid old oil flavor essence;

[0052] Step 3: Add 400 parts of drinking water to another stainless steel blending tank, then add 160 parts of so...

preparation Embodiment 3

[0061]

[0062] Step 1, using first-grade soybean oil as a solvent, respectively prepare butyric acid with a concentration of 1%, acetic acid with a concentration of 1%, 2-methyl-3-mercaptofuran with a concentration of 1%, and furan with a concentration of 1%. Ketoacetate;

[0063] Step 2, adding concentration is 1% butyric acid, concentration is 1% acetic acid, concentration is 1% 2-methyl-3-mercaptofuran, concentration is 1% furanone B Esters, Cumin essential oil at 100%, Capsicum essential oil at 100%, Coriander essential oil at 100%, Nutmeg oil at 100%, Pepper essential oil at 100%, Pepper essential oil at 100% Anise oil, cinnamon oil with a concentration of 100%, clove oil with a concentration of 100%, and first-grade soybean oil with a concentration of 100% are stirred evenly and passed through a 100-mesh sieve to obtain a liquid old oil flavor essence;

[0064] Step 3: Add 400 parts of drinking water to another stainless steel blending tank, then add 160 parts of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com