Hollow fiber desalination membrane assembly and equipment

A desalination membrane and module technology, applied in the field of hollow fiber desalination membrane modules and equipment, can solve the problems of short service period and poor service stability, and achieve the effects of low replacement cost, stable water production and excellent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

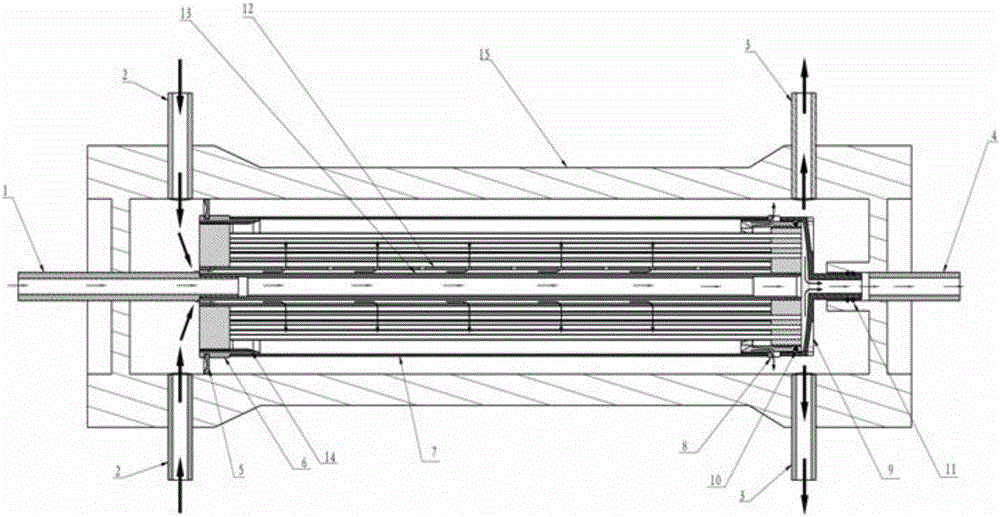

[0026] Embodiment 1: A hollow fiber desalination membrane module is characterized in that it includes a pressure vessel 15 and a desalination membrane unit placed in the pressure vessel; the pressure vessel is provided with a raw water inlet 2 and a concentrated water outlet 3 ; There are two raw water inlets; respectively arranged on the upper and lower parts of the left side of the pressure vessel; there are two concentrated water outlets; respectively arranged on the upper and lower parts of the right side of the pressure vessel lower part. The desalination membrane unit includes a membrane shell 7, and a desalination membrane assembly arranged in the membrane shell; the desalination membrane assembly includes a central water production pipe 13, a central pipe wound around the outer circumference of the central water production pipe. Water inlet pipe 12, a plurality of desalination membrane wires arranged on the outer peripheral side of the central water inlet pipe, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com