Stable-structure high-performance graphene oxide nanofiltration composite membrane and preparation method thereof

A structurally stable, graphene technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing the service life of composite nanofiltration membranes, impairing the separation performance of composite nanofiltration membranes, etc., and achieve excellent structure. Effects of stability, high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

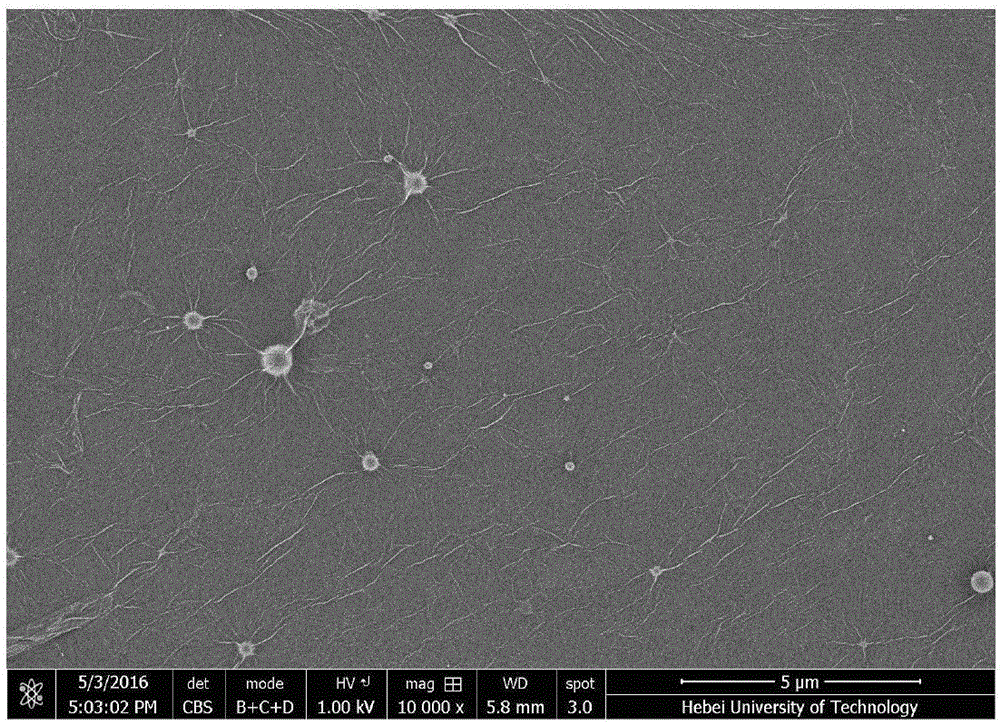

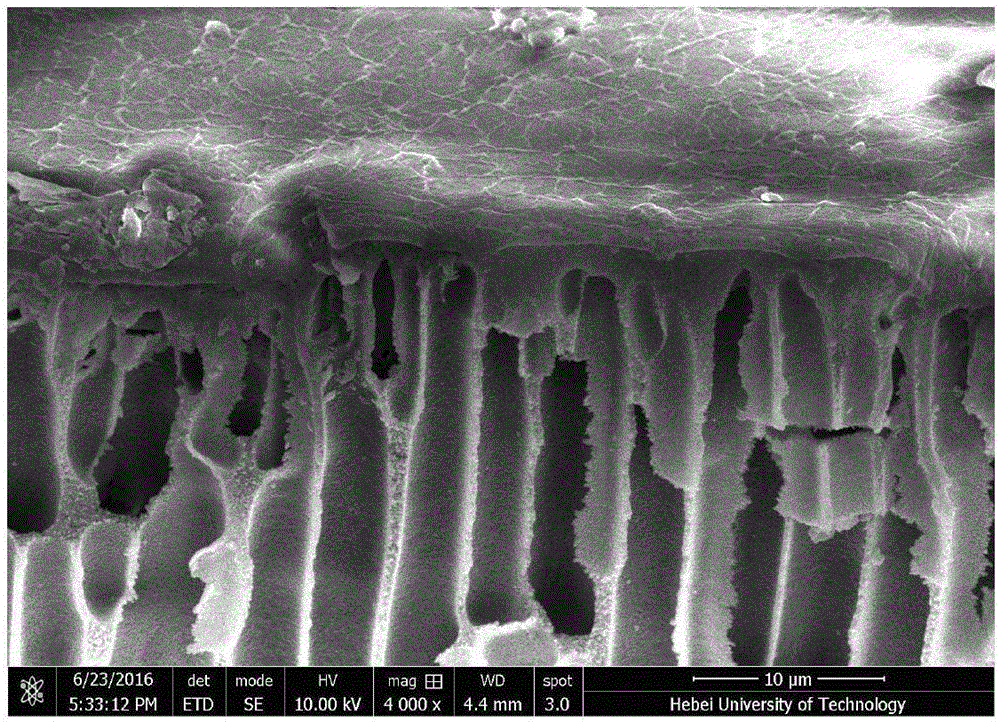

Image

Examples

Embodiment 1

[0029] Preparation of polyethersulfone porous support layer: Blend 12.8g polyethersulfone, 12.8g polyethylene glycol and 54.4g N,N-dimethylformamide into a 250mL three-necked flask, and stir at 65°C for 6h , stand for defoaming, scrape the film with a glass rod, place the obtained liquid film in a gel water bath at room temperature, and transform it into a porous support layer through non-solvent-induced phase inversion. The effective area of the film is 27.2cm 2 , soak the polyethersulfone porous membrane in deionized water, and set aside.

[0030] Dissolve 0.1 g of dopamine in 50 mL of tris aqueous solution with a concentration of 6 g / L to prepare a 2 g / L dopamine aqueous phase solution for subsequent use.

[0031] Disperse 0.163 mg of graphene oxide in 50 mL of deionized water to prepare a graphene oxide aqueous solution for subsequent use.

[0032] Soak the polyethersulfone porous membrane obtained in the above step (1) in a 2g / L dopamine aqueous solution, control the s...

Embodiment 2-4

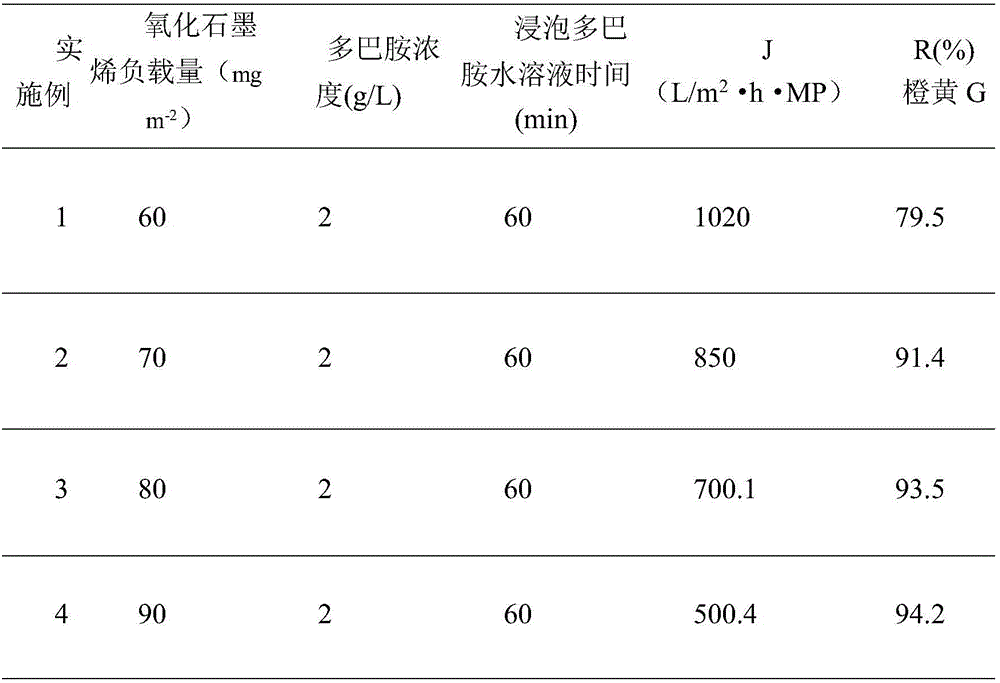

[0035] The volume of the graphene oxide aqueous solution was changed, and the rest are the same as in Example 1. The test results of its flux and selectivity are shown in Table 1.

[0036]

[0037] Example 1-4 is to investigate the influence of the amount of graphene oxide aqueous solution on the performance of the prepared GO-PDA / PES nanofiltration membrane.

example 5-7

[0039] Embodiment 5-7 except that the concentration of dopamine aqueous solution is changed, all the other are the same as embodiment 3

[0040]

[0041]

[0042] Examples 8-10 are to investigate the influence of the concentration of the dopamine aqueous solution on the performance of the prepared GO-PDA / PES nanofiltration composite membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap