Large surface area porous ZrO2 mesoscopic crystal

A technology of mesoscopic crystal and large specific surface, applied in catalyst carrier, chemical/physical process, catalyst activation/preparation, etc., can solve the problems of unfavorable active metal loading, low specific surface area, and no ZrO2 mesocrystal, etc. Excellent catalytic performance, good monodispersity and rich pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 1.28 g of cetyltrimethylammonium bromide, 11.28 g of zirconium oxychloride octahydrate and 4.2 g of urea in 50 mL of deionized water to prepare a mixed solution, and calibrate the above mixed solution to 70 mL with deionized water Then transfer to a high-temperature reactor with a volume of 100 mL (that is, the molar concentration of zirconium oxychloride octahydrate is 0.5 mol / L, and the molar ratio of zirconium oxychloride octahydrate to cetyltrimethylammonium bromide and urea 1:0.05:2). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 150 °C, and the reaction time was 24 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain ZrO 2 mesoscopic crystals.

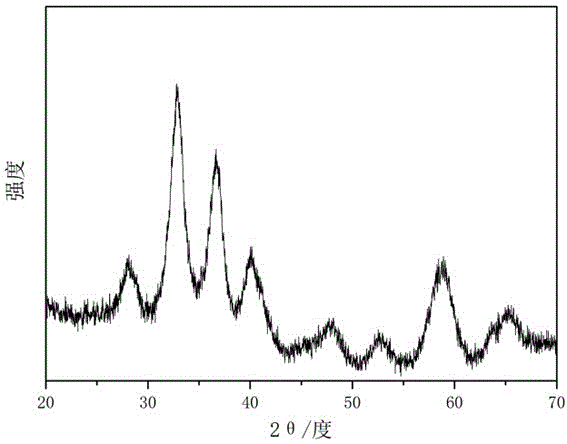

[0026] figure 1 Is the ZrO prepared in this embodiment 2 XRD patterns of mesoscopic crystals. Depend on figure 1 It can be seen that the prepared ZrO 2 Was monoclinic phase.

[0027] figur...

Embodiment 2

[0031] Dissolve 2.04 g of cetyltrimethylammonium bromide, 4.51 g of zirconium oxychloride octahydrate and 1.68 g of urea in 50 mL of deionized water to prepare a mixed solution, and calibrate the above mixed solution to 70 mL with deionized water Transfer volume to be in the high-temperature reactor of 100 mL (namely zirconium oxychloride octahydrate molar concentration is 0.2 mol / L, the molar ratio of zirconium oxychloride octahydrate and cetyltrimethylammonium bromide, urea is 1:0.4:2). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 130 °C, and the reaction time was 48 h. The obtained product was washed by centrifugation to remove impurity ions and then dried at 60 °C for 8 h to obtain ZrO 2 mesoscopic crystals.

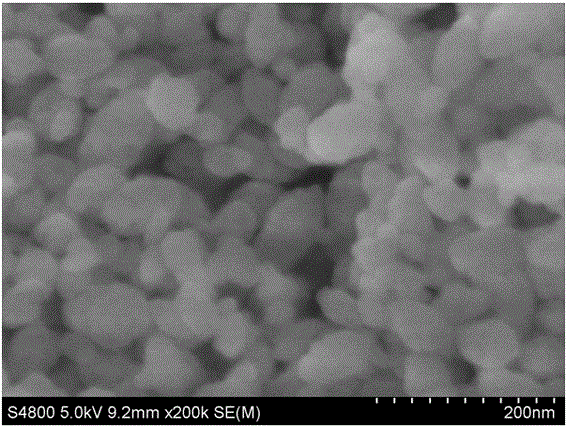

[0032] Figure 5 Is the ZrO prepared in this embodiment 2 SEM images of mesoscopic crystals. Figure 5 It shows that the prepared ZrO 2 The particles are also rice-like mesoscopic crystals.

[0033] N 2 -Phy...

Embodiment 3

[0035] Dissolve 2.55 g of cetyltrimethylammonium bromide, 22.56 g of zirconium oxychloride octahydrate and 8.48 g of urea in 50 mL of deionized water to prepare a mixed solution, and calibrate the above mixed solution to 70 mL with deionized water Then transfer to a high-temperature reactor with a volume of 100 mL (that is, the molar concentration of zirconium oxychloride octahydrate is 1 mol / L, and the molar ratio of zirconium oxychloride octahydrate to cetyltrimethylammonium bromide and urea 1:0.1:2). The reaction kettle was put into a blast drying oven, the reaction temperature was controlled at 200 °C, and the reaction time was 3 h. The obtained product was washed by centrifugation to remove impurity ions, and then dried at 60 °C for 8 h to obtain ZrO 2 mesoscopic crystals.

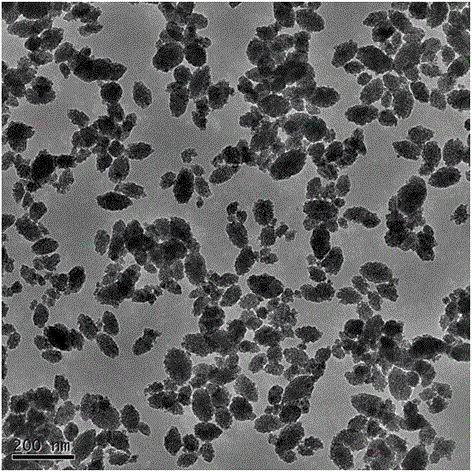

[0036] Figure 6 Is the ZrO prepared in this embodiment 2 SEM images of mesoscopic crystals. Figure 6 It shows that the prepared ZrO 2 The particles are also rice-like mesoscopic crystals.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com