Test tube clamping device, mobile platform provided with test tube clamping device and application method thereof

A clamping device and mobile platform technology, applied in the direction of test tube holder/clamp, laboratory stool/lab table, etc., can solve the problem of low clamping force requirements of mechanical jaws, broken test tubes, a small amount of daily maintenance or maintenance-free, etc. problems, to achieve the effect of low assembly process requirements, easy to use, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

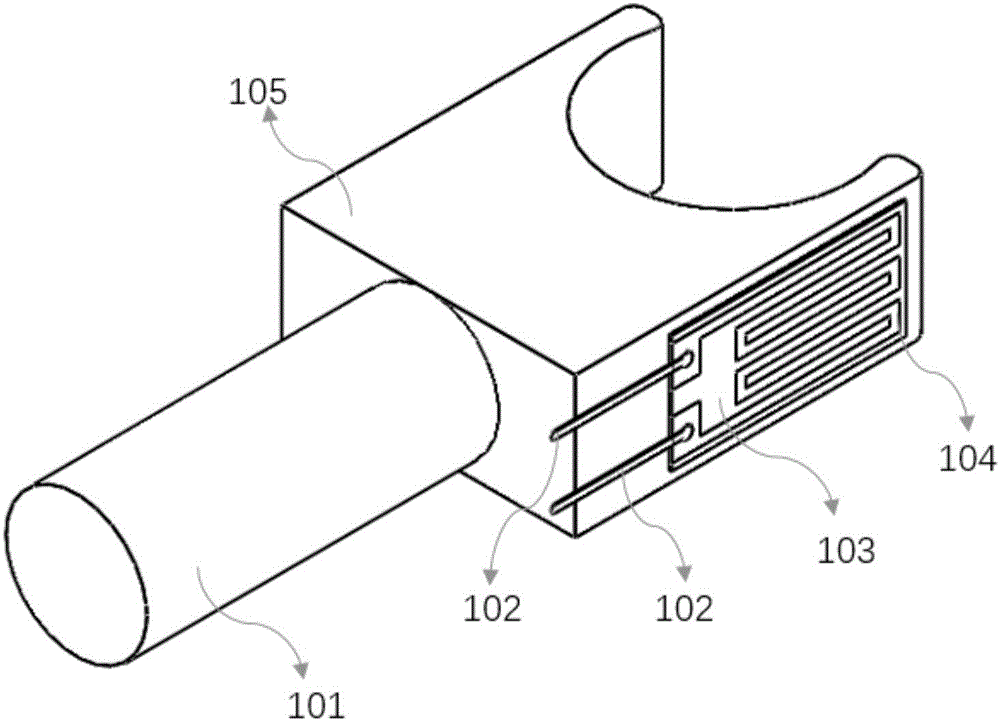

[0041] Such as figure 1 As shown, a test tube clamping device includes a mechanical gripper 105 and a pressure sensor module; the mechanical gripper 105 is used to clamp the test tube; the pressure sensor module is arranged on the working surface of the mechanical gripper 105, and the mechanical gripper The deformation generated when 105 clamps the test tube is transmitted to the pressure sensor module, so that the pressure sensor module generates a corresponding signal output for monitoring the working state of the mechanical gripper 105 (no load / clamping). It has a compact structure and can check in real time whether a test tube is clamped.

[0042] In a preferred embodiment of the present invention, the mechanical jaw 105 includes an annular clamping portion provided with an opening, wherein the size of the opening is smaller than the diameter of the clamped part of the test tube to be clamped; the material of the mechanical jaw 105 be metal or plastic. The process of gri...

Embodiment 2

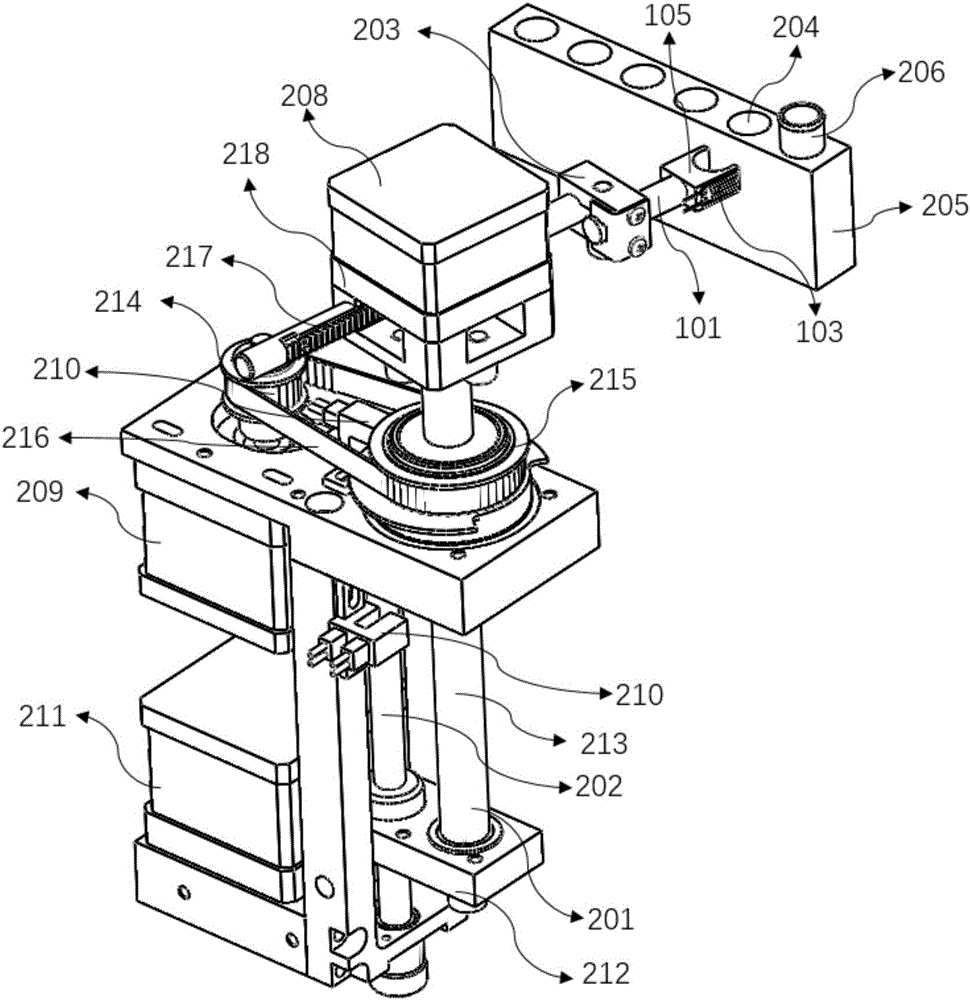

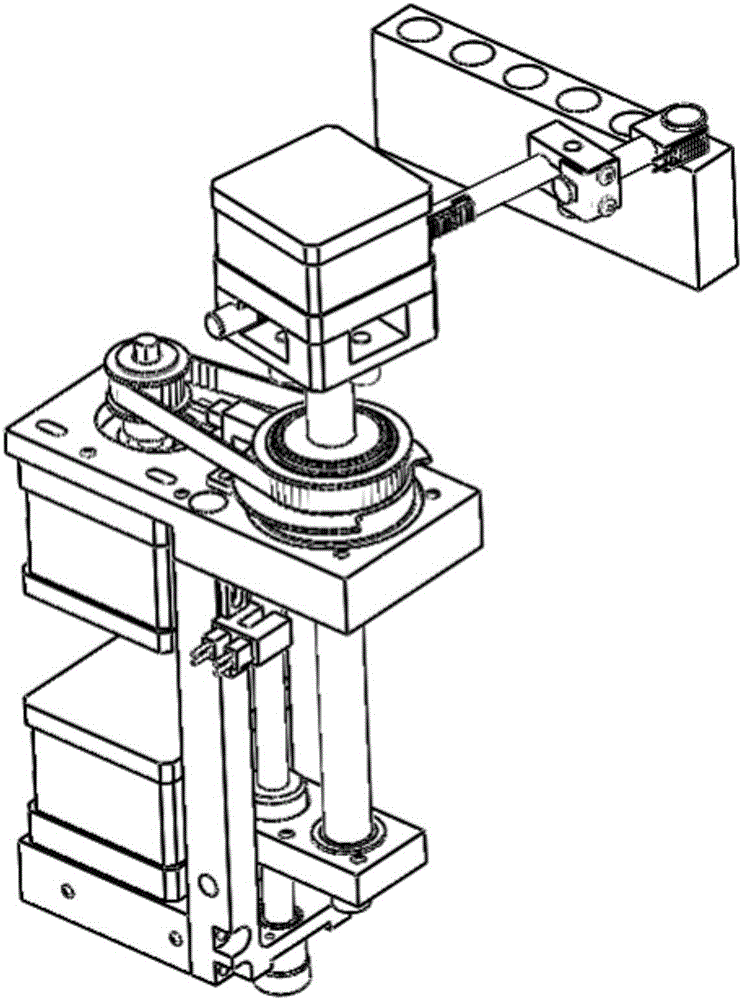

[0048] Such as figure 2 As shown, a mobile platform with a test tube clamping device includes a support frame, a first linear motion mechanism, a circular motion mechanism, a second linear motion mechanism and any one of claims 1-4 arranged on the support frame The test tube clamping device described in Item 1; the first linear motion mechanism drives the circular motion mechanism to perform lifting motion in the vertical direction, and the circular motion mechanism drives the second linear motion mechanism to perform R-axis rotation on the horizontal plane; the second linear motion mechanism The motion mechanism is connected with the test tube clamping device (preferably, the end of the second linear motion mechanism is connected with the test tube clamping device through the fourth connecting block 203), which drives the test tube clamping device to do linear motion back and forth in the horizontal direction; The first linear motion mechanism, the circular motion mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com