Kitchen waste three-grade separation pretreatment process

A technology for kitchen waste and pretreatment, which is used in the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of great damage to subsequent process equipment and high impurity content, and achieve a clean and tidy production environment. High impurity removal rate and fine sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

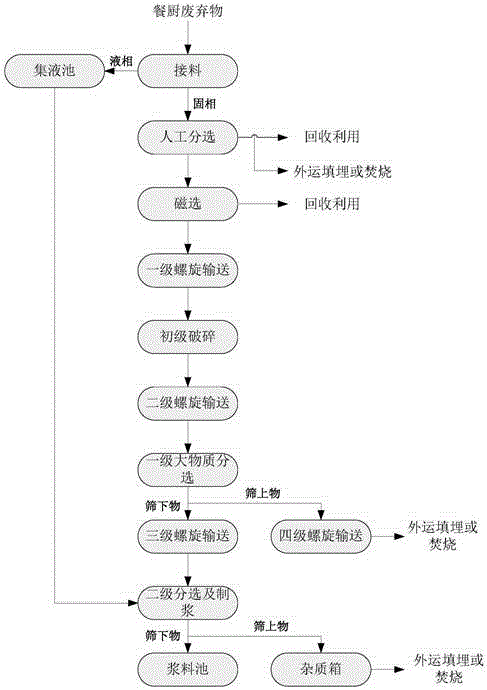

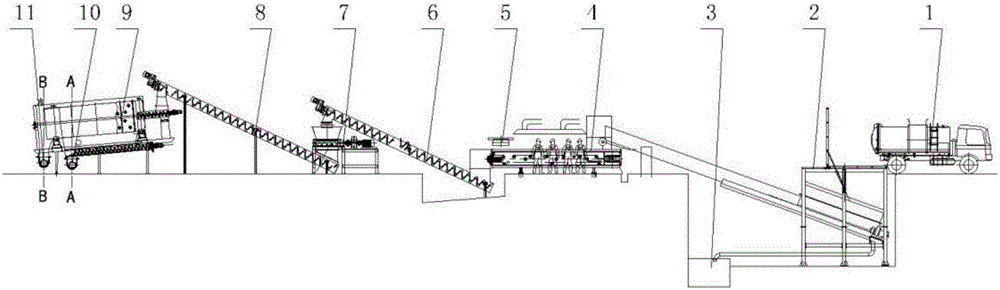

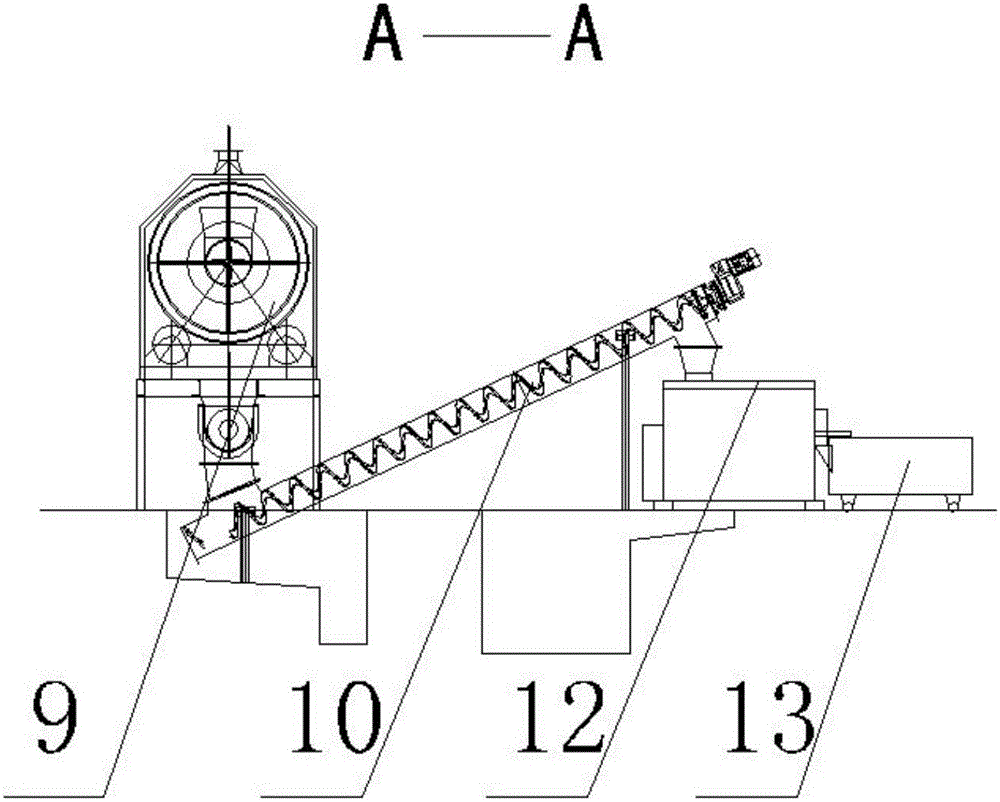

[0028] Example: refer to Figure 1-Figure 4 , a three-stage separation and pretreatment process for kitchen waste, including the following steps:

[0029] (1) Receiving

[0030] The kitchen waste collected by Sinotrans is directly poured into the material receiving device 2, and the preliminary solid-liquid separation is realized through the extrusion and drainage of the material receiving device 2, and the solid phase is transported to the manual sorting equipment through the auger of the material receiving device 2 4 goes up; The material receiving device 2 has the functions of material storage, odor prevention, solid-liquid separation, and material transportation. The solid-liquid separation can initially separate 50% of the water in the kitchen waste, and use a screw conveyor to carry out the material for the subsequent process. Transport creates conditions.

[0031] (2) Manual sorting

[0032] A closed manual sorting room is built for manual sorting, and it is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com