A powder metallurgy method for forming functionally graded materials based on selective laser melting

A functionally graded material, powder metallurgy technology, applied in the direction of additive processing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of high forming cost, high cost, long cycle, etc., to reduce processing cycle and reduce production cost. , the effect of reducing the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of a small engine nozzle made of tungsten-copper functionally graded material.

[0023] a. According to the use characteristics of the small engine nozzle, the material of the formed part is tungsten-copper functionally graded material, the outer diameter is 100mm, the inner diameter is 80mm, and the height is 100mm. Among them, the copper content change gradient is 15%, 20%, 25%, 30%, and the gradient layer thickness is 25mm, which are respectively called the first gradient layer, the second gradient layer, the third gradient layer, and the fourth gradient layer.

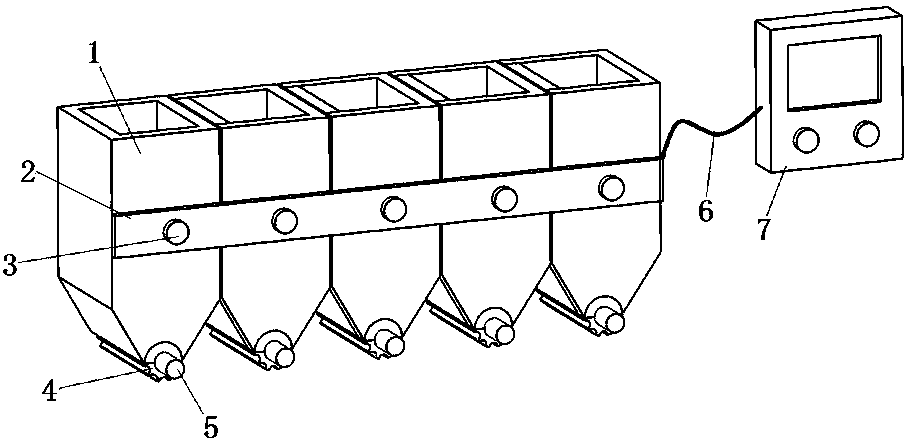

[0024] b. Loading, put tungsten-copper alloy powder with copper content of 15%, 20%, 25%, and 30% into different feeding cylinders respectively. The structure of the feeding cylinder is: bolt 3 fixes feeding cylinder 1 on the beam 2, a roller 4 with a wheel groove is installed at the bottom of the feeding cylinder, the roller is controlled by a motor 5, and the motor 5 is connected to the control...

Embodiment example 2

[0031] Preparation of an aluminum-based SiC functionally graded material heat-resistant plate.

[0032] a. The heat-resistant plate material is an aluminum-based SiC functionally graded material with a size of 100×80×15mm (length, width and height). The aluminum substrate is ZL101, and the SiC content changes in the height direction are: 0.6%, 0.8%, 1.0%, 0.8%, 0.6%, and the thickness of the gradient layer is 3mm, respectively called the first gradient layer, the second gradient layer, and the second gradient layer. The third gradient layer, the fourth gradient layer, and the fifth gradient layer.

[0033] b. Loading, change the content of SiC to: 0.6%, 0.8%, 1.0%, 0.8%, 0.6% respectively figure 1 There are 5 feeding cylinders in the structure, the structure of the feeding cylinder is as follows: the bolt 3 fixes the feeding cylinder 1 on the beam 2, the bottom of the feeding cylinder is equipped with a roller 4 with a wheel groove, the roller is controlled by the motor 5, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com