A method for rapid preparation of biomimetic superhydrophobic surfaces of titanium alloys by femtosecond laser

A super-hydrophobic surface, femtosecond laser technology, used in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of adverse effects on the operator's environment, cumbersome processes, etc., to achieve excellent and durable super-hydrophobic performance, simple process, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for rapidly preparing a biomimetic superhydrophobic surface of a titanium alloy by using a femtosecond laser, the steps are as follows:

[0043] S1. Pretreatment: Pretreatment of titanium alloy surface, including rough grinding, fine grinding, polishing and cleaning of titanium alloy surface;

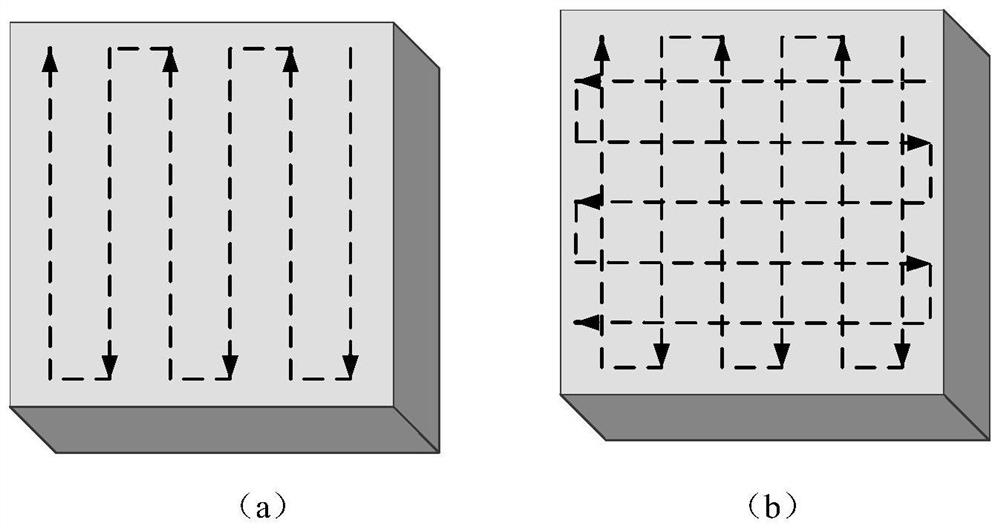

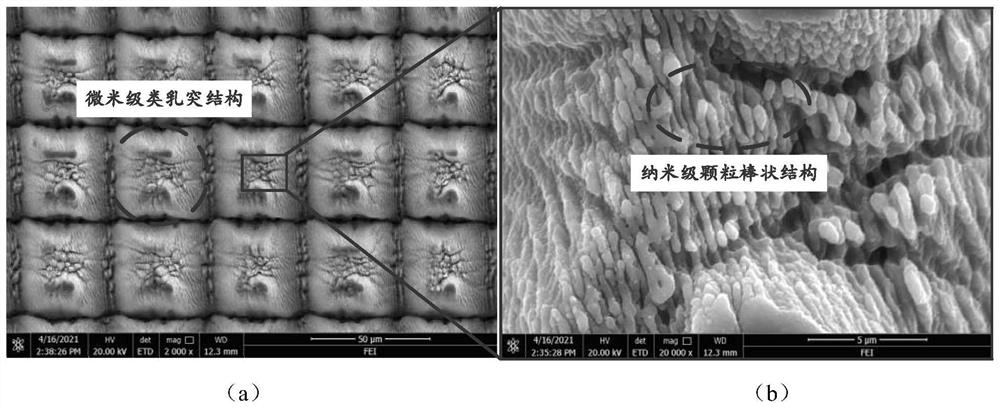

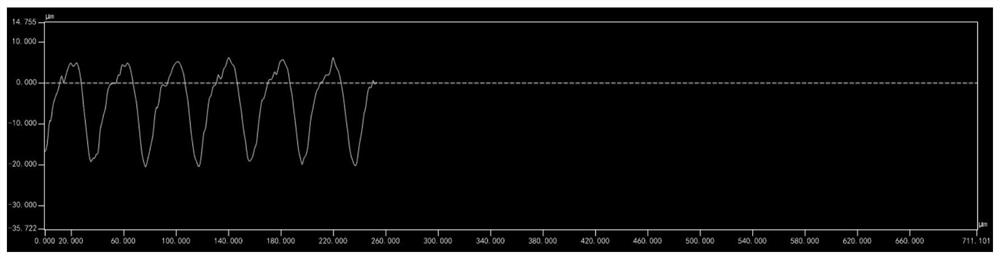

[0044] S2. Laser etching: Femtosecond laser is used to perform laser etching on the surface of the titanium alloy after pretreatment, and a dual-scale micro-nano structure is formed on the surface of the titanium alloy, that is, an ordered periodic micro-scale emulsion is formed on the surface of the titanium alloy. Protruding structure, the papillary-like structure is densely distributed with nano-scale particle rod-like structure, and after laser etching, the molten particles or impurity particles ablated on the surface of the titanium alloy are removed by cleaning;

[0045] The specific parameters of the laser etching are: the laser wavelength is 1030 nm, the laser sp...

Embodiment 2

[0051] A method for rapidly preparing a biomimetic superhydrophobic surface of a titanium alloy by using a femtosecond laser, the steps are as follows:

[0052] S1. Pretreatment: Pretreatment of titanium alloy surface, including rough grinding, fine grinding, polishing and cleaning of titanium alloy surface;

[0053] S2. Laser etching: Femtosecond laser is used to perform laser etching on the surface of the titanium alloy after pretreatment, and a dual-scale micro-nano structure is formed on the surface of the titanium alloy, that is, an ordered periodic micro-scale emulsion is formed on the surface of the titanium alloy. Protruding structure, the papillary-like structure is densely distributed with nano-scale particle rod-like structure, and after laser etching, the molten particles or impurity particles ablated on the surface of the titanium alloy are removed by cleaning;

[0054] The specific parameters of the laser etching are: the laser wavelength is 1030 nm, the laser sp...

Embodiment 3

[0058] This embodiment is basically the same as the second embodiment, and the only difference is the laser etching parameters in step S2.

[0059] In this example, the specific parameters of the laser etching in step S2 are: the laser wavelength is 1030 nm, the laser spot size is 30 μm, the laser pulse width is 275 fs, the single pulse energy is 3.4 μJ, the frequency is 700 kHz, the scanning speed is 700 mm / s, and the scanning speed is 700 mm / s. The pitch was 10 μm, the number of scans was 30, and the scan path was grid-like.

[0060] The static contact angle of the titanium alloy surface prepared in this example was measured on a contact angle meter, and the static contact angle was 151.2°, which met the requirement of superhydrophobic surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com