Overall assembling system and method achieving multi-vehicle free switching

A multi-vehicle, free technology, applied to vehicle parts, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of loose structure, unfavorable production operation, and unfavorable layout of large-scale assembly systems, and achieve safe and reliable control accuracy and production High-tempo, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

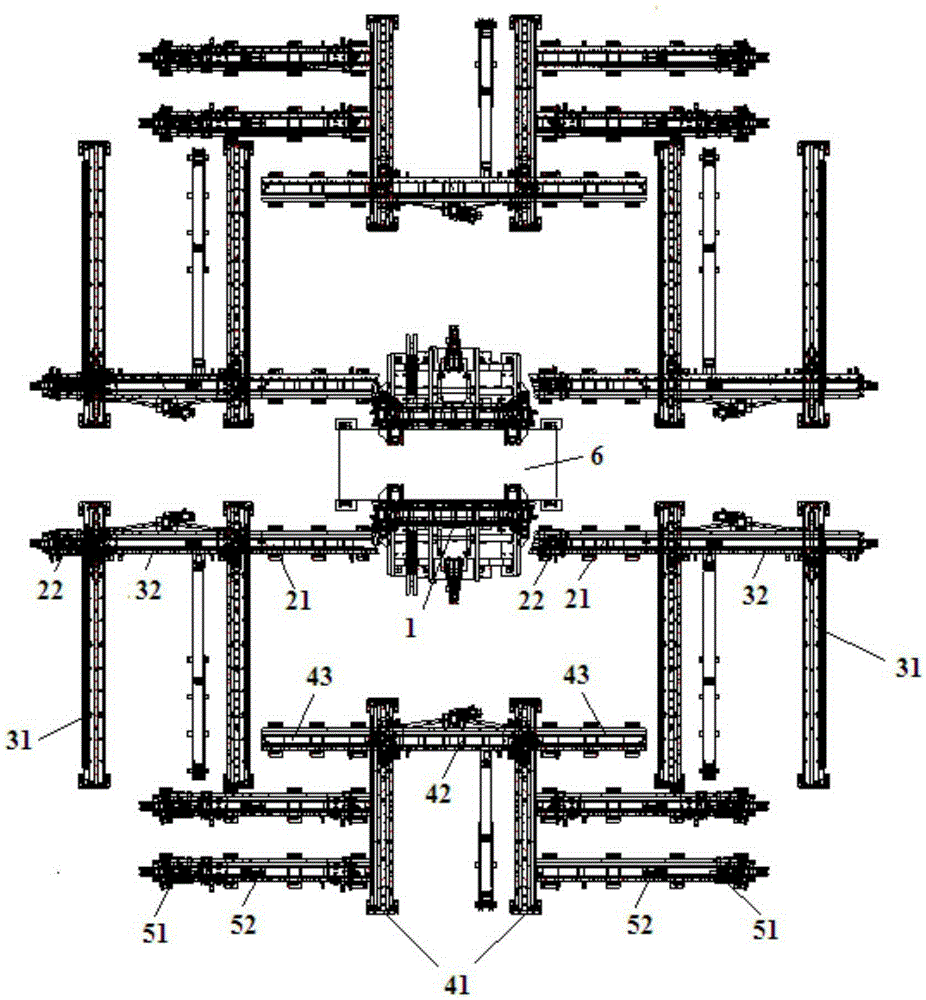

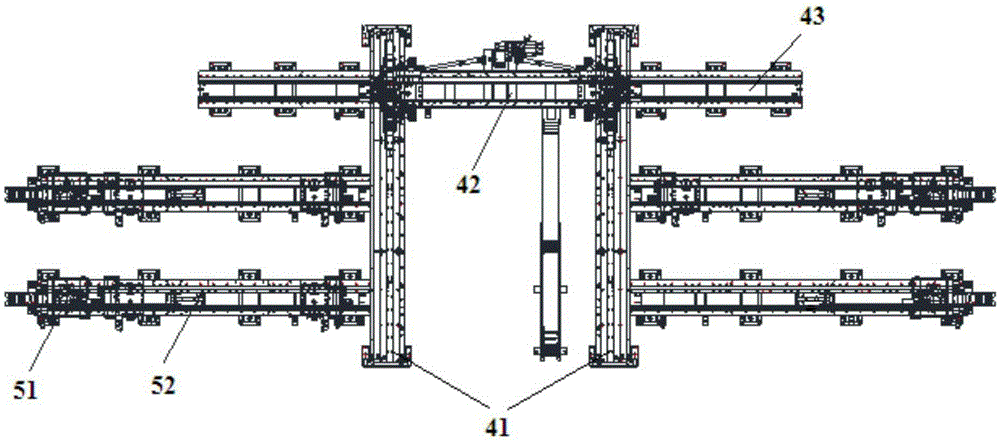

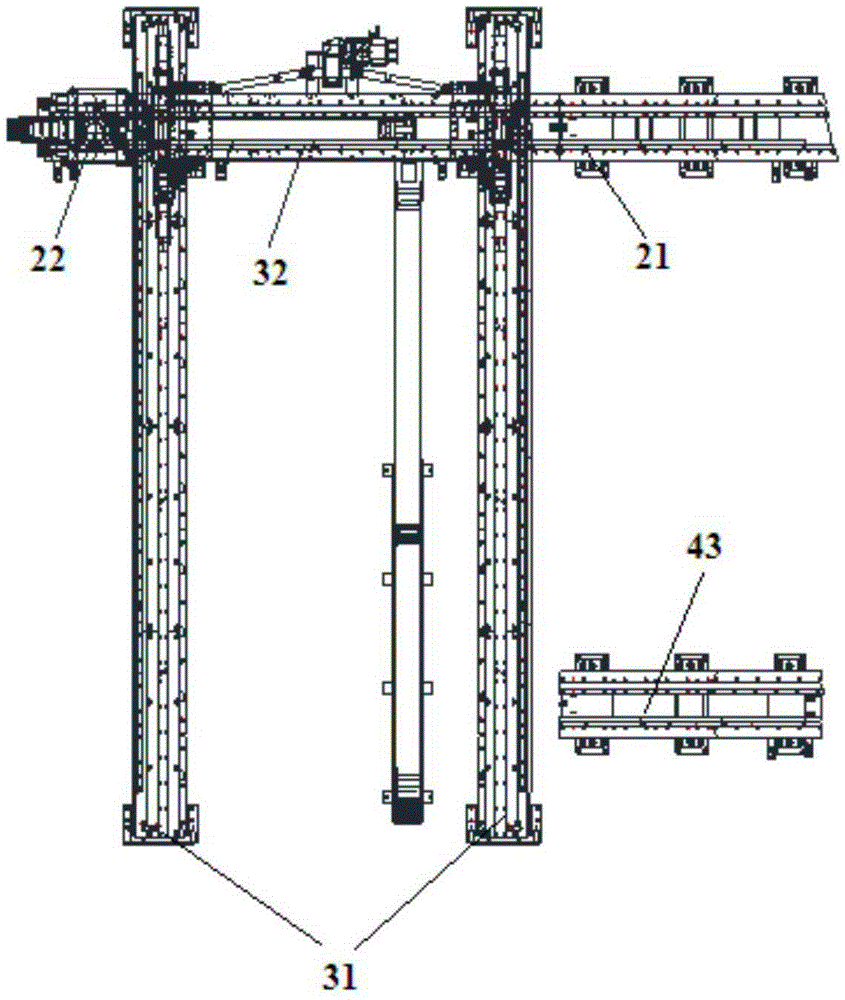

[0033] Such as Figure 1-3 As shown, a general assembly system with free switching of multiple vehicle models is used to adapt to the fixed welding of different vehicle models in white. The control components are connected with the total assembly subsystem, and each total assembly subsystem includes:

[0034] Storage and placement table: includes multiple fixture storage positions for placing combined fixtures corresponding to different models, and each combined fixture is equipped with a bottom connector of the fixture;

[0035] Storage and positioning device: used to grab and transport the combined fixture from the fixture storage position of the storage placement table through the bottom connector of the fixture and transport it to the predetermined grabbing position, and return the replaced combined fixture;

[0036] Combined assembly positioning device: used to grab the corresponding combined fixture from the predetermined grabbing position and transport it to the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com