Loop heat pipe evaporator assembling tool and assembling method

A technology for assembling tooling and loop heat pipes, used in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easy breakage, difficult deformation control, stuck capillary core, etc., to ensure product life and reliability. , to meet the small batch production, to avoid the effect of bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

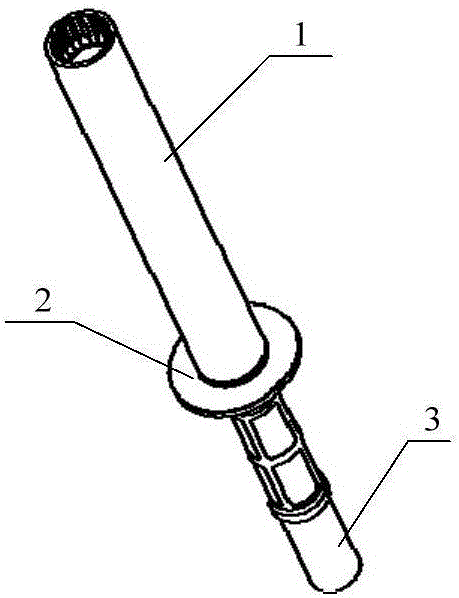

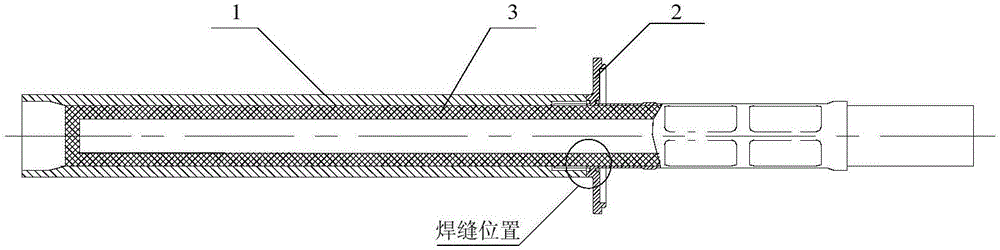

[0067] An assembly tool for a loop heat pipe evaporator, the assembly tool includes a first set of tools, a second set of tools and a third set of tools;

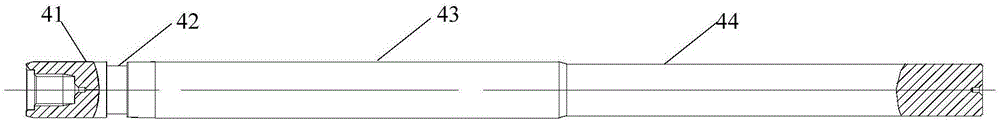

[0068] Such as Figure 5 As shown, the first set of tooling includes a mandrel 4, a counterweight 5, a limit block 6, a connecting rod 7, an upper plate 8, a support column 9, and a bottom plate 10;

[0069] Such as Figure 7 As shown, the second set of tooling includes a mandrel 4, a counterweight 5, a limit block 6, a main shell B support seat 11, a connecting rod 2 12, an upper plate 8, a support column 9, and a bottom plate 10;

[0070] Such as Figure 8 , Figure 9 and Figure 10 As shown, the third set of tooling includes a counterweight 5, an upper plate 8, a support column 9, a bottom plate 10, a limit support rod 13, an external threaded sleeve 14, an internal threaded sleeve 15, a protective terminal 16, and a main shell pull Cover 17, steel ball 18, steel ball seat 19, capillary core seat 20, collet 21.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com