Ink-jet printing system for 3D bent glass cover plate and ink-jet machining method thereof

A curved glass and inkjet printing technology, which is applied to printing devices, printing, typewriters, etc., can solve the problems of difficult formation of customized patterns or graphics, secondary pollution, and broken nets, so as to achieve no risk of secondary pollution, The effect of simplifying the printing process and overcoming technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with examples.

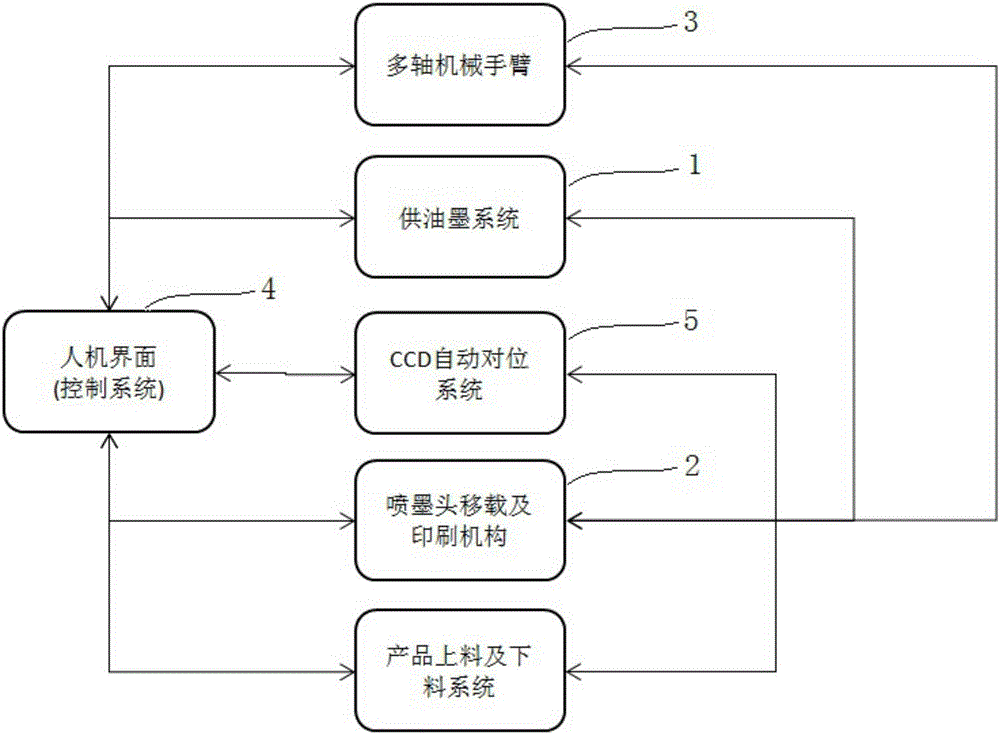

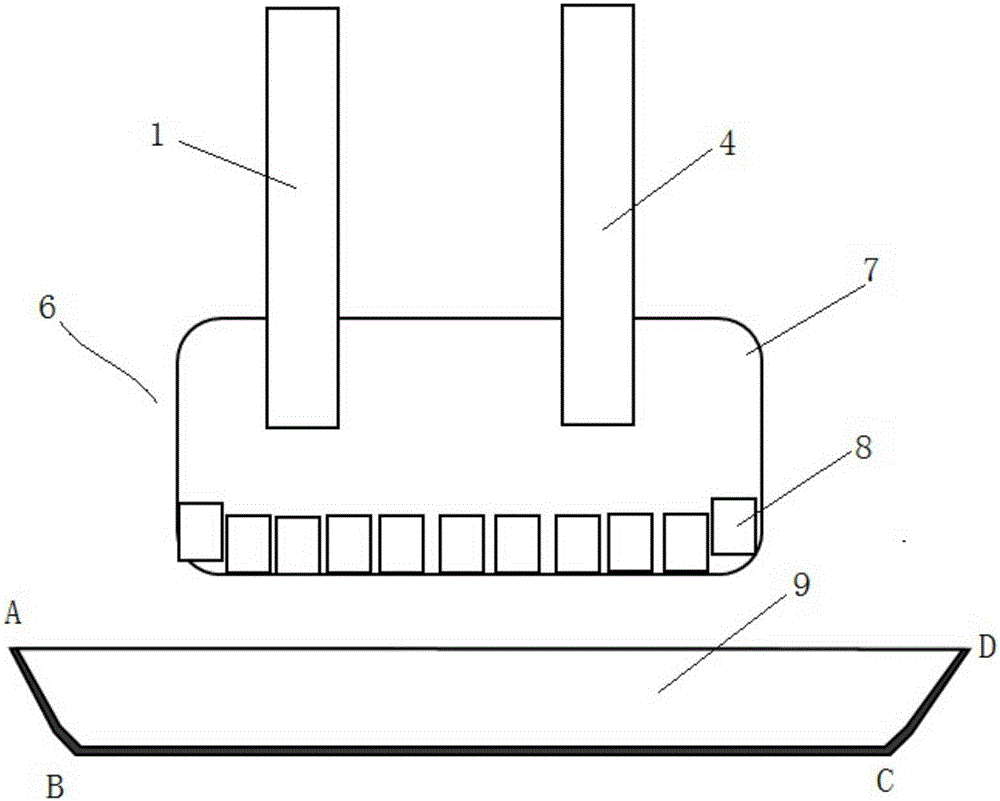

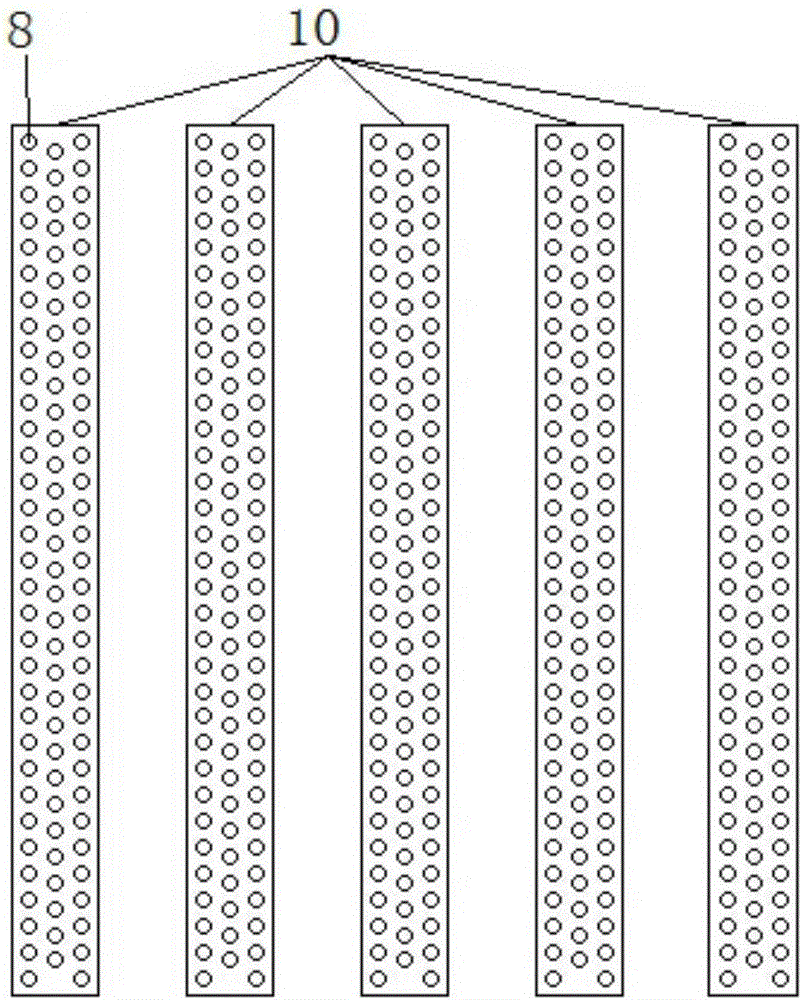

[0031] figure 1 A structure diagram of an inkjet printing system for a 3D curved glass cover is given. In this embodiment, the inkjet printing system includes an ink supply system 1 , an inkjet head transfer and printing mechanism 2 , a multi-axis robot arm 3 and a control system 4 . The control system 4 is also called a man-machine interface, and has signal links with the ink supply system 1 , the inkjet head transfer and printing mechanism 2 , and the multi-axis robot arm 3 . As a preference of this embodiment, the inkjet printing system further includes a product loading and unloading system, the product loading and unloading system is used to transfer the 3D curved glass cover plate 9 to be printed, and the product loading and unloading system The system also establishes data communication with the control system 4 . The operating instructions of the control system 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com