Technology for fusing carbon-carbon bonds of carbon nanotubes by means of electron beam irradiation

An electron beam irradiation, carbon nanotube technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as excessive melting, relative position and contact gap effects, carbon nanotube damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

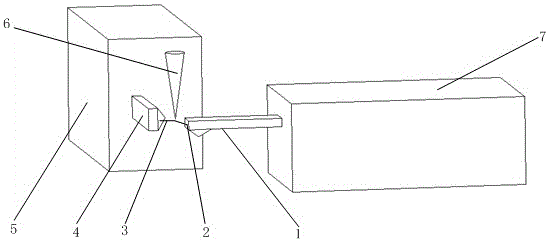

[0047] The present invention provides a technology for fusing carbon nanotubes by irradiating carbon-carbon bonds with electron beams, including:

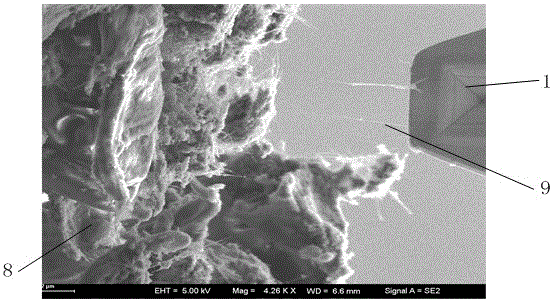

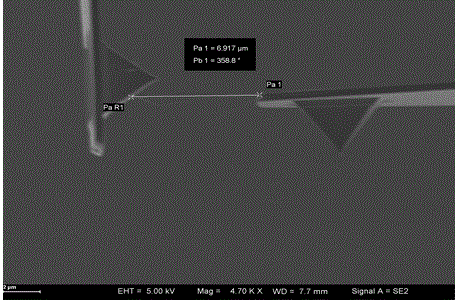

[0048] a) extracting multi-walled carbon nanotubes (9) using atomic force microscope probe 1 (1);

[0049] b) Lap the multi-walled carbon nanometer (9) onto the atomic force microscope probe 2 (4), and pull it off;

[0050] c) Two sections of multi-walled carbon nanotubes are in contact with each other, and the focused electron beam is irradiated at the joint through a scanning electron microscope. The electron energy of the irradiated electron beam is partially converted into the electron energy of the electrons outside the carbon nucleus, and the carbon is made according to the law of energy conservation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com