Compound SrCdGeS4 and preparation method thereof, and infrared nonlinear optical crystal as well as preparation method and application thereof

A technology of nonlinear optics and compounds, applied in nonlinear optics, germanium compounds, chemical instruments and methods, etc., to achieve the effects of low cost, fast growth, easy processing and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

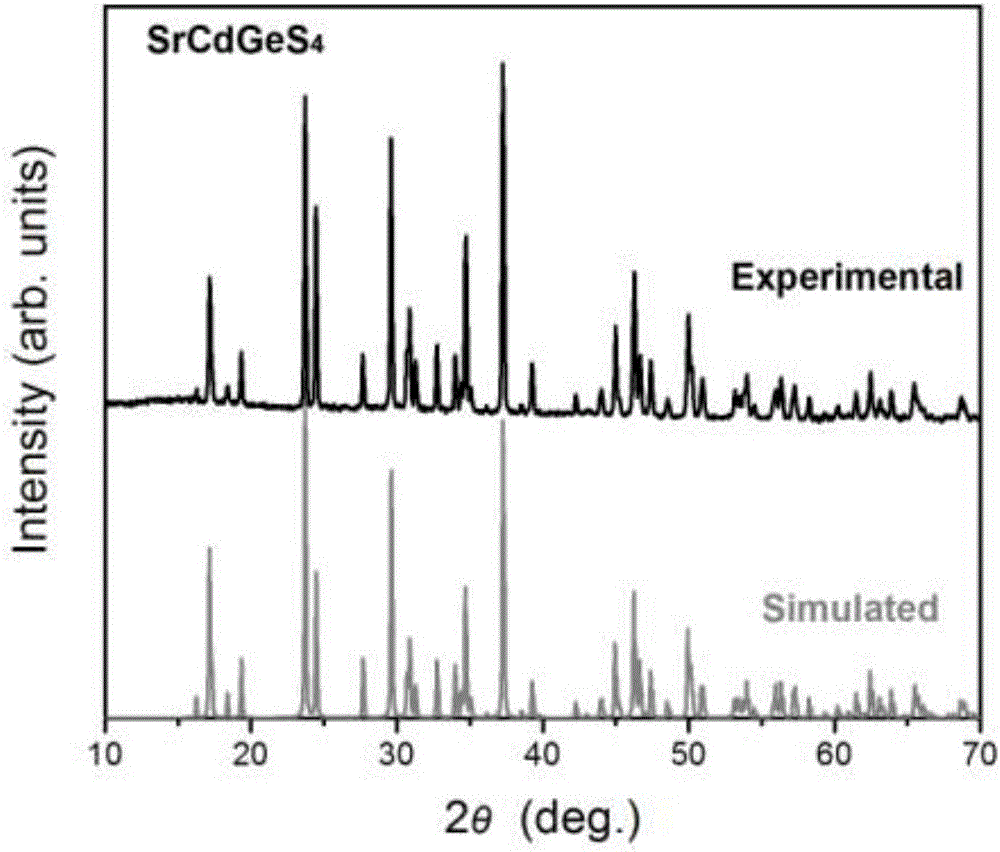

[0033] Embodiment 1 prepares powdery SrCdGeS 4 compound

[0034] Using SrS+CdS+GeS 2 =SrCdGeS 4 Preparation of SrCdGeS by High Temperature Solid State Reaction 4 Compound; The SrS is 5.985 grams, the CdS is 7.224 grams, and the GeS 2 It is 6.837 grams; that is, SrS:CdS:GeS 2 =0.05mol:0.05mol:0.05mol.

[0035] The specific operation steps are: weigh the reagents according to the above dosage in the glove box, put them into a mortar, mix and grind them, then put them into a Φ19mm×25mm quartz tube, and evacuate them to 10 -3 After Pa, the quartz tube was melted and packaged with a hydrogen-oxygen flame, put into a muffle furnace, raised to 800 °C at a rate of 40 °C / h, and kept for 96 hours. After cooling, the sample was taken out, ground and mixed, and then placed in the quartz tube Vacuum-encapsulated in the middle, sintered in a muffle furnace at 750°C for 48 hours, the sample shrunk into a block; take it out, put it into a mortar, crush and grind it to obtain powdered Sr...

Embodiment 2

[0036] Embodiment 2 prepares powdery SrCdGeS 4 compound

[0037] Using SrS+Cd+Ge+3S=SrCdGeS 4 Preparation of SrCdGeS by High Temperature Solid State Reaction 4 Compound; the SrS is 5.985 grams, the Cd is 5.621 grams, the Ge is 3.631 grams, and the S is 4.810 grams, that is, SrS:Cd:Ge:S=0.05mol:0.05mol:0.05mol:0.15mol ;

[0038] The specific operation steps are to weigh the reagents in the glove box according to the above doses, put them into a Φ19mm×25mm quartz tube, and evacuate to 10 -3 After Pa, the quartz tube was melted and packaged with a flame, put into a muffle furnace, slowly raised to 850°C, the heating rate was 20°C / h, and kept for 96h, after cooling, the sample was taken out, ground and mixed, and then placed in the quartz tube Vacuum-encapsulated in a tube, sintered in a muffle furnace at 750°C for 48 hours, the sample shrank into a block; it was taken out, crushed and ground in a mortar to obtain powdered SrCdGeS 4 compound.

Embodiment 3

[0039] Embodiment 3 prepares powdery SrCdGeS 4 compound

[0040] Using SrS+Cd+GeS 2 +S=SrCdGeS 4 Preparation of SrCdGeS by High Temperature Solid State Reaction 4 Compound; The SrS is 5.985 grams, the Cd is 5.621 grams, and the GeS 2 is 6.837 grams, and the S is 1.603 grams, namely SrS:Cd:GeS 2 :S=0.05mol:0.05mol:0.05mol:0.05mol;

[0041] The specific operation steps are to weigh the reagents in the glove box according to the above doses, put them into a Φ19mm×25mm quartz tube, and evacuate to 10 -3 After Pa, the quartz tube was melted and packaged with a flame, put into a muffle furnace, slowly raised to 800°C, the heating rate was 20°C / h, and kept for 96h. After cooling, take it out, take out the sample, grind and mix, and then place Vacuum-encapsulated in a tube, sintered in a muffle furnace at 750°C for 48 hours, the sample shrank into a block; it was taken out, crushed and ground in a mortar to obtain powdered SrCdGeS 4 compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com