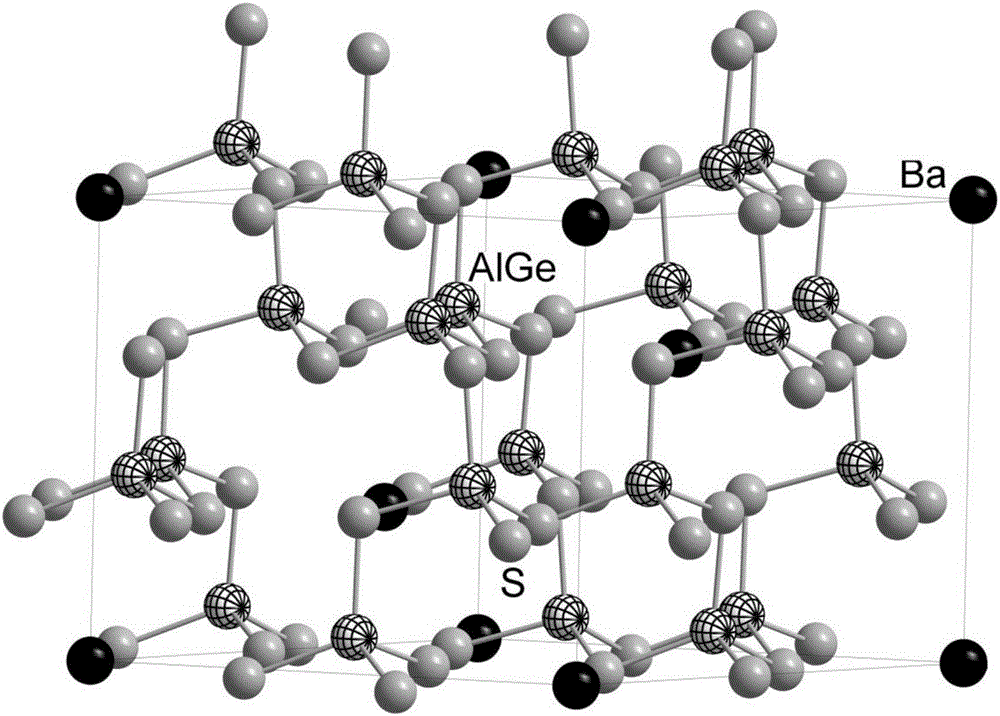

Sulfur-germanium-aluminum-barium compound, preparation method of sulfur-germanium-aluminum-barium compound, sulfur-germanium-aluminum-barium crystal and preparation method and application of sulfur-germanium-aluminum-barium crystal

A barium compound and compound technology, applied in germanium compounds, chemical instruments and methods, crystal growth and other directions, can solve the problems of difficult crystal growth, large anisotropic thermal expansion, low thermal conductivity, etc., and achieve easy processing, preservation, growth and so on. High speed and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Using BaS+2Al+GeS 2 +3S=BaAl 2 GeS 6 The reaction formula is to prepare sulfur germanium aluminum barium compound by high temperature solid state reaction method;

[0044] The BaS is 6.776 grams, the Al is 2.158 grams, the GeS 2 It is 5.470 grams; the S is 3.848 grams; namely BaS:Al:GeS 2 : S=0.04mol:0.08mol:0.04mol:0.12mol;

[0045] The specific operation steps are: weigh the reagents according to the above dosage in the glove box, put them into a mortar, mix and grind them, then put them into a Φ19mm×25mm quartz tube, and evacuate them to 10 -3 After Pa, the quartz tube was melted and packaged with a hydrogen-oxygen flame, put into a muffle furnace, raised to 900 °C at a rate of 40 °C / h, and kept for 96 hours. After cooling, the sample was taken out, ground and mixed, and then placed in the quartz tube Medium-pumped vacuum package, sintered in a muffle furnace at 800°C for 72h; take it out, put it into a mortar, crush and grind it to get powdered BaAl 2 GeS 6 c...

Embodiment 2

[0047] Adopt BaS+2Al+Ge+5S=BaAl 2 GeS 6 The reaction formula is to prepare sulfur germanium aluminum barium compound by high temperature solid state reaction method;

[0048] Described BaS is 6.776 grams, and described Al is 2.158 grams, and described Ge is 2.904 grams; Described S is 6.413 grams; Namely BaS:Al:Ge:S=0.04mol:0.08mol:0.04mol:0.20mol;

[0049] The specific operation steps are: weigh the reagents according to the above dosage in the glove box, put them into a mortar, mix and grind them, then put them into a Φ19mm×25mm quartz tube, and evacuate them to 10 -3 After Pa, the quartz tube was melted and packaged with a hydrogen-oxygen flame, put into a muffle furnace, raised to 850 °C at a rate of 30 °C / h, and kept for 96 hours. After cooling, the sample was taken out, ground and mixed, and then placed in the quartz tube Medium-pumped vacuum package, sintered in a muffle furnace at 800°C for 72h; take it out, put it into a mortar, crush and grind it to get powdered Ba...

Embodiment 3

[0051] Adopt Ba+2Al+Ge+6S=BaAl 2 GeS 6 The reaction formula is to prepare sulfur germanium aluminum barium compound by high temperature solid state reaction method;

[0052] Described Ba is 5.493 grams, and described Al is 2.158 grams, and described Ge is 2.904 grams; Described S is 7.696 grams; Namely Ba:Al:Ge:S=0.04mol:0.08mol:0.04mol:0.24mol;

[0053] The specific operation steps are to weigh the reagents in the glove box according to the above doses, put them into a Φ19mm×25mm quartz tube, and evacuate to 10 -3 After Pa, the quartz tube was melted and packaged with a flame, put into a muffle furnace, slowly raised to 900°C, the heating rate was 20°C / h, and kept for 96h. After cooling, take it out, take out the sample, grind and mix, and then place Vacuumize the package in a tube, sinter in a muffle furnace at 800°C for 72 hours; take it out, put it in a mortar, crush and grind it to obtain powdered BaAl 2 GeS 6 compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com