Urban comprehensive sewage treatment process

A sewage treatment and process technology, applied in the field of urban comprehensive sewage treatment process, can solve the problems of large surplus sludge output, high operating costs, high energy consumption, etc., and achieve the effect of saving sludge treatment costs and improving effluent water quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

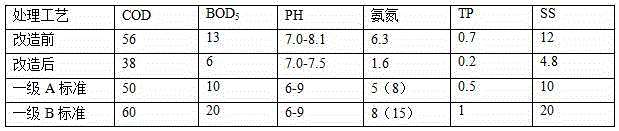

[0061] Jiangyin Yuantong Comprehensive Sewage Treatment Co., Ltd., the water treatment volume is 10,000 tons / day, and the influent concentration before treatment is COD≤440mg / L, BOD 5 ≤260mg / L, PH≤4, ammonia nitrogen≤35mg / L, TP≤5.5mg / L, SS≤300mg / L.

[0062] The effluent of the original process is required to meet the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" GB18918-2002 Class I B standard. Now the standard has been upgraded, and the treated effluent can meet the "Urban Sewage Treatment Plant Pollutant Discharge Standards" GB18918-2002 Class A A standard .

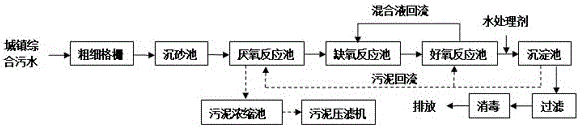

[0063] The original treatment process mainly adopts the AAO method combined with the enhanced physical and chemical method. Now it is modified according to this process. The process flow is as follows

[0064] Steps:

[0065] (1) The comprehensive urban sewage pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com