Method for realizing maximal accumulation of nitrite in sludge fermentation coupling denitrification process

A nitrite and denitrification technology, applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as long start-up time, unstable accumulation of nitrite, complicated control process, etc. , to achieve the effects of short start-up time, stable nitrite accumulation, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

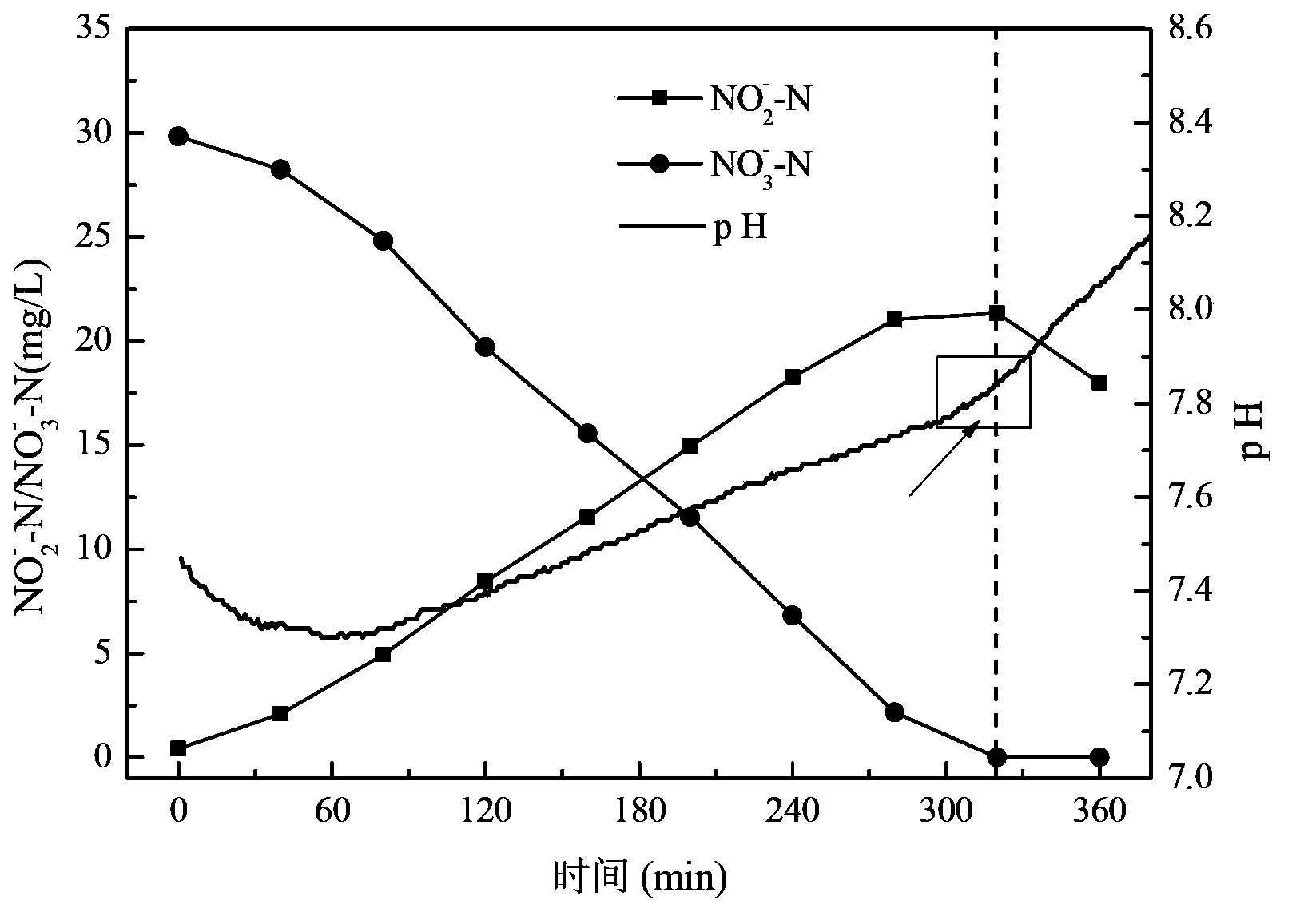

[0026] This method is further described in conjunction with specific experimental examples and accompanying drawings:

[0027] The SBR reactor was used for the nitrite accumulation test in the denitrification process, and the effective capacity of the reactor was 5L; each cycle of the SBR reactor included water inflow for 10 minutes, anoxic stirring for 240-400 minutes, precipitation for 60 minutes, and then the supernatant was discharged. 50%.

[0028] The specific test includes the following steps:

[0029] (1) Inoculate the sludge of the sludge fermentation coupling denitrification system, and control the sludge concentration MLSS after influent to 2000-2500mg / L; Activated sludge in the nitrification reactor, the sludge fermentation coupling denitrification reactor adopts alternate anaerobic / anoxic operation mode, the sludge age SRT is 20-28 days; each cycle of anaerobic stirring fermentation is 6-8h, and then the pump NO 3 - -N wastewater, where NO 3 - -N=35~55mg / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com