High-efficiency denitrification device and method capable of releasing self-reinforced solid carbon source

A solid carbon source and high-efficiency technology, applied in anaerobic digestion treatment, sustainable biological treatment, waste fuel, etc., can solve problems such as excessive concentration of organic matter in effluent, incomplete reduction of nitrate, and difficulty in regulating carbon source dosage, etc., to achieve Enhanced release efficiency, improved reaction rate and nitrite accumulation rate, and improved carbon source utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

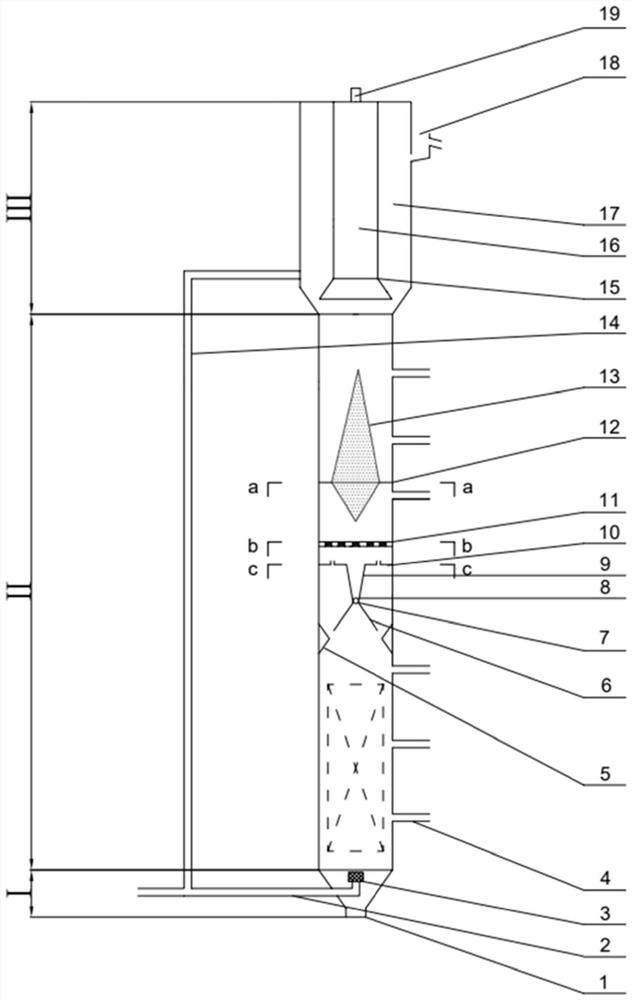

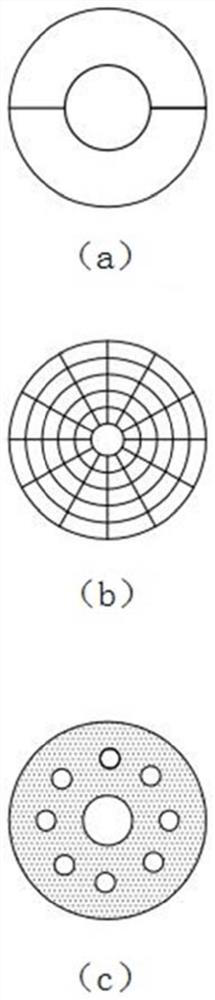

[0031] The present invention will be further elaborated and described below with reference to the accompanying drawings and specific embodiments. The technical features of the various embodiments of the present invention can be combined correspondingly on the premise that there is no conflict with each other.

[0032] like figure 1 As shown in the figure, it is a high-efficiency denitrification device released from a self-strengthening solid carbon source provided by the present invention. The high-efficiency denitrification device includes a water distribution and sludge discharge device I, a reaction device II and a three-phase separation device III, which are sequentially connected from bottom to top. . The structure and connection mode of each device will be described in detail below.

[0033] The water distribution and sludge discharge device 1 is a structure in which the lower part is gradually reduced and has an inner cavity, and the bottom is provided with a mud discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com