Enzyme treatment process for organic wastewater containing mercaptans and sulfides

An enzyme treatment and thioether technology, which is applied in the field of enzyme treatment technology, can solve the problems of difficult disposal and high treatment cost, and achieve the effects of reducing sludge production, reducing operating costs, and reducing the dosage of Fenton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

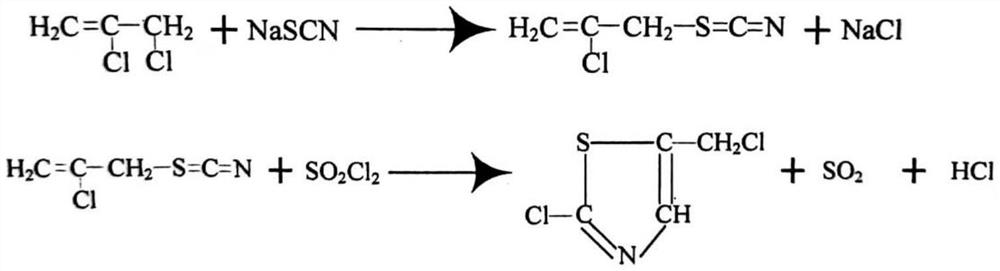

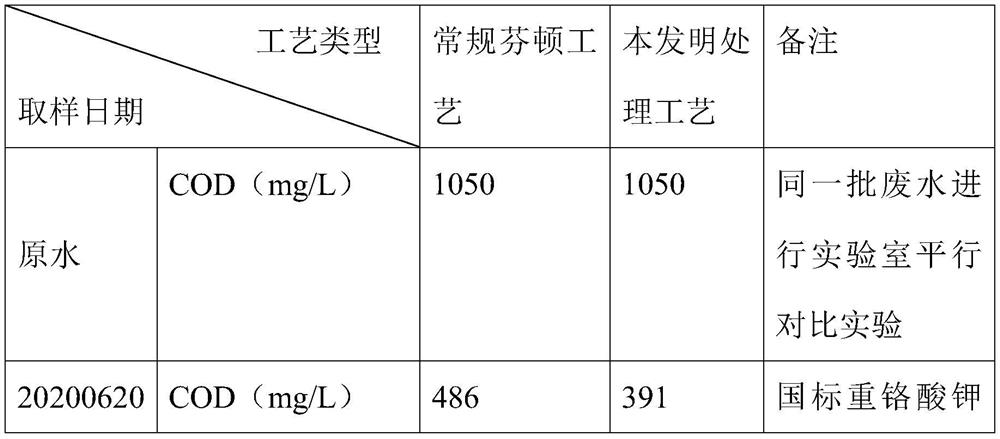

[0024] Embodiment 1: Enzyme treatment process of 2-chloro-5-chloromethylthiazole production process wastewater

[0025]

[0026] 2-Chloro-5-chloromethylthiazole production process wastewater contains sodium thiocyanide, methylthiazole intermediates, and a small amount of 2-chloro-5-chloromethylthiazole, sodium chloride, produced by conventional Fenton oxidation A large amount of chemical sludge needs to be disposed of as hazardous chemical waste, and the cost of sludge disposal in the later stage is high. Using the process route of the present invention can effectively improve the disposal efficiency and reduce the dosage of chemicals, thereby reducing the amount of sludge generated from the source.

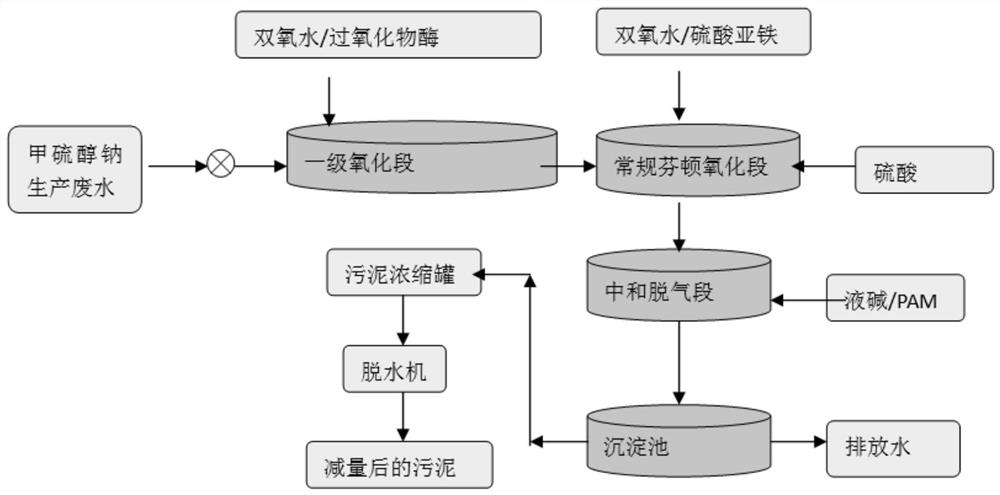

[0027] Such as figure 1 As shown, the specific operation steps:

[0028] (1) Take 1000ml of water sample, adjust the pH of the waste water at 5-6, the temperature at 40-60 degrees Celsius, the amount of peroxidase complex (enzyme activity index greater than 50,000 enzyme acti...

Embodiment 2

[0038] Example 2: Enzyme Treatment Process Containing Xanthate Wastewater

[0039] Wastewater containing xanthate is derived from the waste gas spray absorption tower in the production process of xanthate. The main component is non-methane total hydrocarbon sulfide (all volatile hydrocarbons other than methane, mainly C 2 -C 8 ), the COD concentration is 1000-5000mg / L.

[0040] Such as figure 1 As shown, the specific operation steps:

[0041] (1) Take 1000ml of water sample, adjust the pH of the waste water at 5-6, the temperature at 30-40 degrees Celsius, the amount of peroxidase complex (enzyme activity index greater than 50,000 enzyme activity units): 0.05% of the total amount of waste water , Peroxidase compound enzyme ratio: chloroperoxidase, Phanerochaete chrysosporium peroxidase mixed according to the weight ratio of 1:1, 30% hydrogen peroxide (COD and 30% hydrogen peroxide weight ratio: 1:0.25 ), using stirring form, the concentration of dissolved oxygen in wastewa...

Embodiment 3

[0051] Embodiment 3: Enzyme treatment process of methionine production wastewater

[0052] Methionine production wastewater contains methionine, methyl mercaptan, ethanethiol, dimethyl sulfide, diethyl sulfide, and dimethyl disulfide. After anaerobic-aerobic biochemical treatment, it enters the pilot test device for further The state of the water is continuous water inflow, COD=90-110mg / L.

[0053] Such as figure 1 As shown, the specific operation steps:

[0054] (1) Take 1000ml of water sample, adjust the pH of the waste water at 5-6, the temperature at 30-40 degrees Celsius, the amount of peroxidase complex (enzyme activity index greater than 50,000 enzyme activity units): 0.05% of the total amount of waste water , Peroxidase compound enzyme ratio: chloroperoxidase, Phanerochaete chrysosporium peroxidase mixed according to the weight ratio of 1:1, 30% hydrogen peroxide (COD and 30% hydrogen peroxide weight ratio: 1:0.3 , adopt stirring form, dissolved oxygen concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com