Ordered double-layer film micro-spherical shell structure glass and manufacturing method thereof

A manufacturing method, technology of shell structure, applied in the direction of final product manufacturing, sustainable manufacturing/processing, coating, etc., can solve problems such as low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

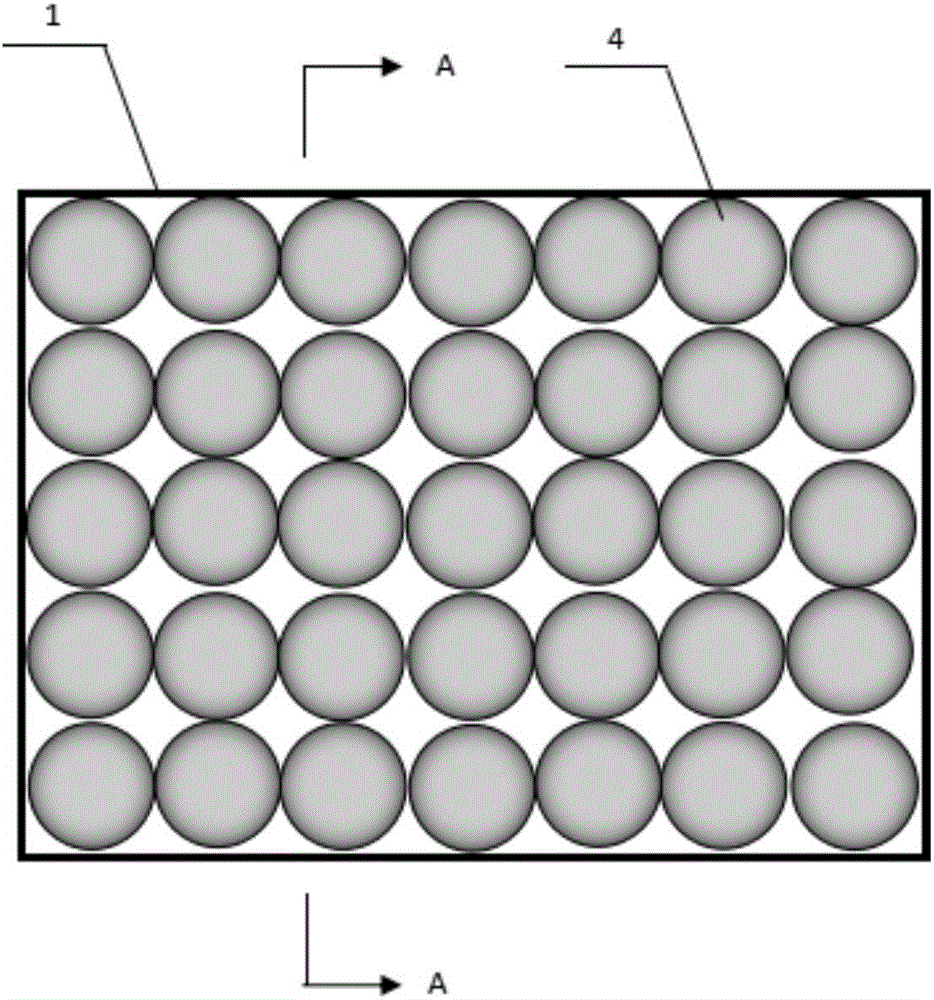

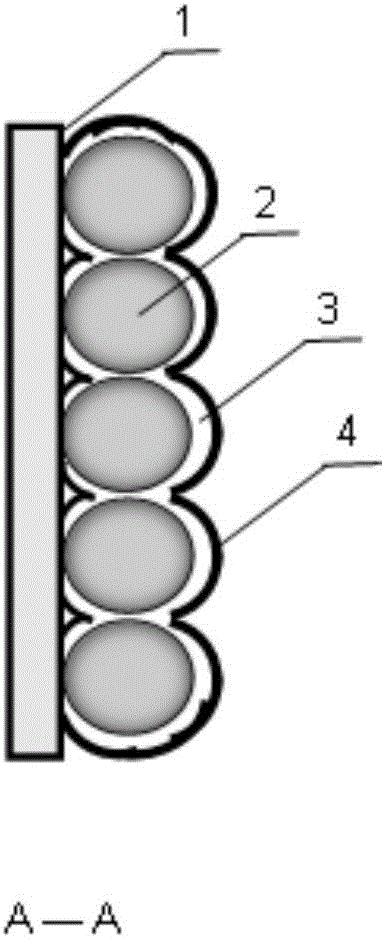

[0070] refer to figure 1 , figure 2 , the present embodiment is the ICS / AZO double-layer film microsphere shell structure glass of orderly and dense arrangement, and the microsphere shell structure glass plate (1) is flat plate, and its area is 560 square centimeters; SiO 2 The scale of the microsphere 2 is 0.6 micron; the thickness of the first spherical shell ICS is 150 nanometers; the thickness of the second spherical shell AZO is 180 nanometers. The coverage area of the first layer of spherical shell ICS is the surface area of the complete microsphere; the coverage area of the second layer of spherical shell AZO is the surface area of the complete microsphere.

[0071] A method for manufacturing ICS / AZO double-layer film microsphere shell structure glass with ordered and dense arrangement, comprising the following steps:

[0072] Step 1, prepare a layer of closely arranged SiO microspheres:

[0073] The silicon-containing ethanol reaction solution is synthesize...

Embodiment 2

[0091] refer to figure 1 , figure 2 , the present embodiment is the ICS / AZO double-layer film microsphere shell structure glass of orderly and dense arrangement, and the microsphere shell structure glass plate (1) is flat plate, and its area is 560 square centimeters; SiO 2 The scale of the microsphere 2 is 0.6 micron; the thickness of the thin film ICS is 130 nanometers; the thickness of the thin film AZO is 160 nanometers. The coverage area of the first layer of spherical shell ICS is the surface area of the complete microsphere; the coverage area of the second layer of spherical shell AZO is the surface area of the complete microsphere.

[0092] A method for manufacturing ICS / AZO double-layer film microsphere shell structure glass with ordered and dense arrangement, comprising the following steps:

[0093] Step 1, prepare a layer of closely arranged SiO microspheres:

[0094] The silicon-containing ethanol reaction solution is synthesized by hydrolysis polyconde...

Embodiment 3

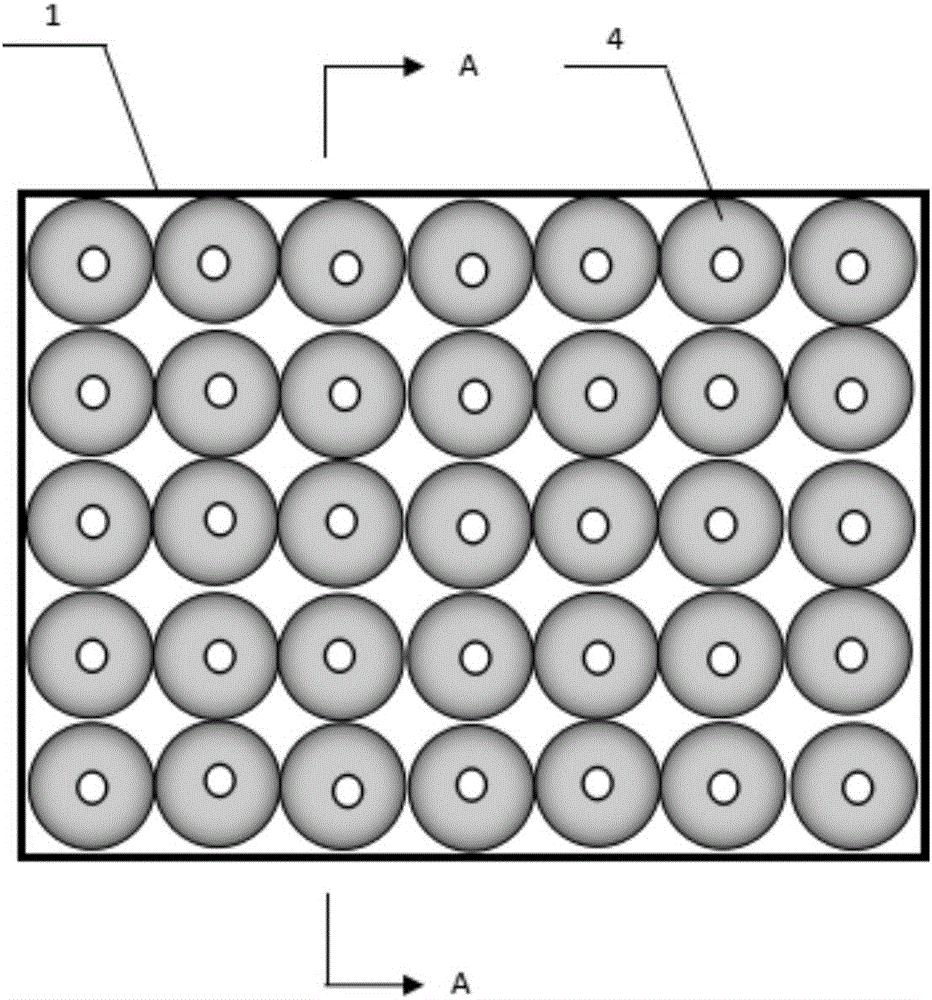

[0112] refer to image 3 , Figure 4 , the present embodiment is the ICS / AZO double-layer film microsphere shell structure glass of orderly and dense arrangement, and the microsphere shell structure glass plate (1) is flat plate, and its area is 560 square centimeters; SiO 2 The scale of the microspheres is 0.6 microns; the thickness of the thin film ICS is 165 nm; the thickness of the thin film AZO is 188 nm. The coverage area of the first layer of spherical shell ICS is the surface area of the complete microsphere minus the top 1 / 8 spherical cap of the upper surface of the microsphere; the coverage area of the second layer of spherical shell AZO is the surface area of the complete microsphere minus The upper surface of the microsphere is topped by a 1 / 8 spherical cap.

[0113] A method for manufacturing ICS / AZO double-layer film microsphere shell structure glass with ordered and dense arrangement, comprising the following steps:

[0114] Step 1, prepare a layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com