Method for adsorbing phenylethyl alcohol

A technology of phenylethanol and adsorbent, which is applied in the field of separation and enrichment of natural components, can solve the problems of lack of simple and feasible methods for separating and purifying natural 2-phenylethanol, and achieve high selectivity, high separation efficiency and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) under stirring condition, put 1.57ml 2-phenylethanol in 3000ml deionized water, seal, stir 48h at room temperature, be mixed with the fermentation liquid that contains 2-phenylethanol, the concentration of 2-phenylethanol in the described fermentation liquid is 521.2mg / kg, which is close to the concentration of phenylethanol in real fermentation broth.

[0022] (2) the fermented liquid that step (1) obtains and adsorbent SiO 2 -P is mixed in contact, and the dosage ratio during mixing is: every 250mL of fermentation broth corresponds to 0.25g of adsorbent.

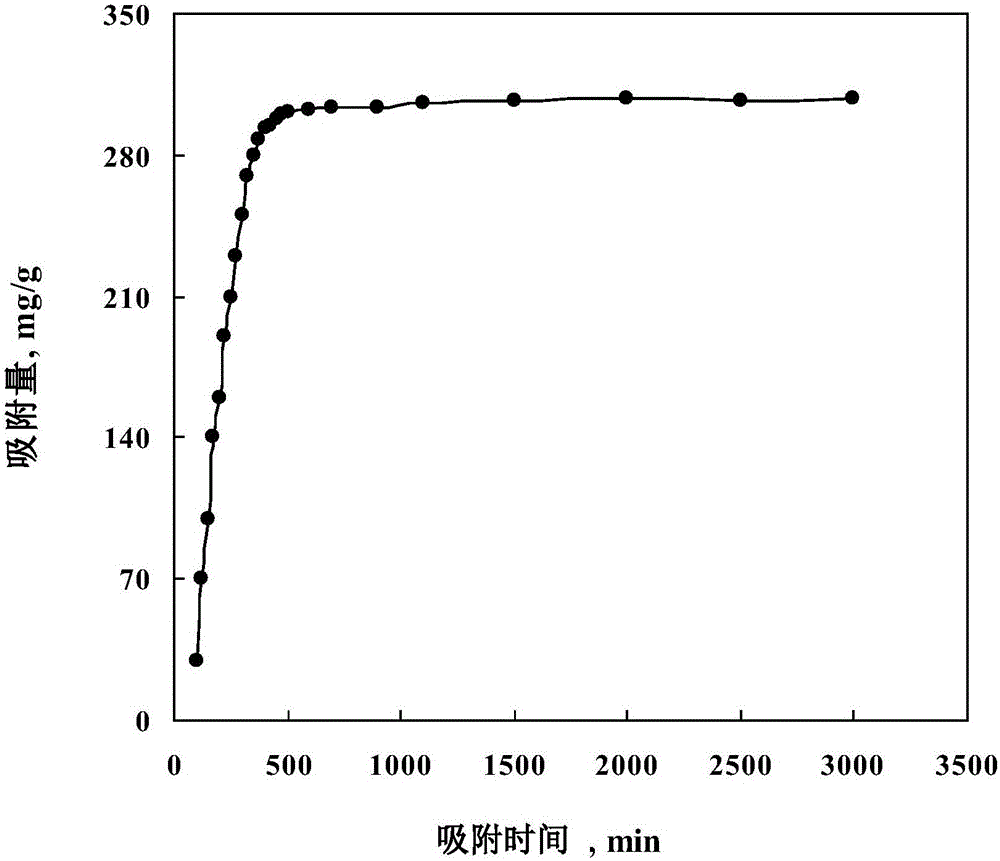

[0023] (3) Carry out adsorption experiment on the mixed solution obtained in step (2) on a TAITECMM-10 type oscillator, the oscillation rate of the oscillator is 120rpm, operate at room temperature 298K, pipette 2ml solution at regular intervals, and filter through a microporous membrane , measure the concentration of phenethyl alcohol in the filtrate by HPLC, and calculate SiO accordingly 2 -Absorptive amount...

Embodiment 2

[0026] (1) under stirring condition, put 1.35ml 2-phenylethanol in 3000ml deionized water, seal, stir 48h at room temperature, be mixed with the fermented liquid that contains 2-phenylethanol, the concentration of 2-phenylethanol in the described fermented liquid is 448.2mg / kg, which is close to the concentration of phenylethanol in real fermentation broth.

[0027] (2) the fermented liquid that step (1) obtains and adsorbent SiO 2 -P is mixed in contact, and the dosage ratio during mixing is: every 250mL of fermentation broth corresponds to 0.25g of adsorbent.

[0028] (3) Carry out adsorption experiment on the mixed solution obtained in step (2) on a TAITECMM-10 type oscillator, the oscillation rate of the oscillator is 120rpm, operate at room temperature 298K, pipette 2ml solution at regular intervals, and filter through a microporous membrane , measure the concentration of phenethyl alcohol in the filtrate by HPLC, and calculate SiO accordingly 2 -Absorptive amount of P....

Embodiment 3

[0031] (1) under stirring condition, put 1.79ml 2-phenylethanol in 3000ml deionized water, seal, stir 48h at room temperature, be mixed with the fermentation liquid that contains 2-phenylethanol, the concentration of 2-phenylethanol in the described fermentation liquid is 594.2mg / kg, which is close to the concentration of phenylethanol in real fermentation broth.

[0032] (2) the fermented liquid that step (1) obtains and adsorbent SiO 2 -P is mixed in contact, and the dosage ratio during mixing is: every 250mL of fermentation broth corresponds to 0.25g of adsorbent.

[0033] (3) Carry out the adsorption experiment on the mixed solution obtained in step (2) on the TAITECMM-10 type oscillator, the oscillation rate of the oscillator is 150rpm, operate under the room temperature of 298K, pipette 2ml solution at regular intervals, and filter through the microporous membrane , measure the concentration of phenethyl alcohol in the filtrate by HPLC, and calculate SiO accordingly 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com