Water-soluble fluorescent whitening agent for coarse whiting powder as well as preparation method and application thereof

A technology of heavy calcium carbonate powder and fluorescent whitening agent, applied in the field of fluorescent whitening agent, can solve the problems of fluorescent whitening materials lacking heavy calcium carbonate powder, etc., and achieves strong ultraviolet absorption performance, good water solubility, Good fluidity and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

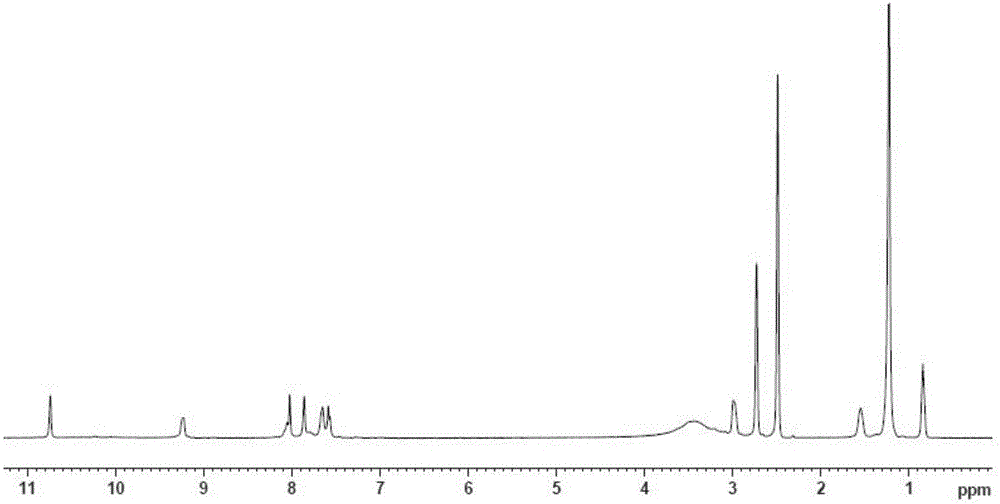

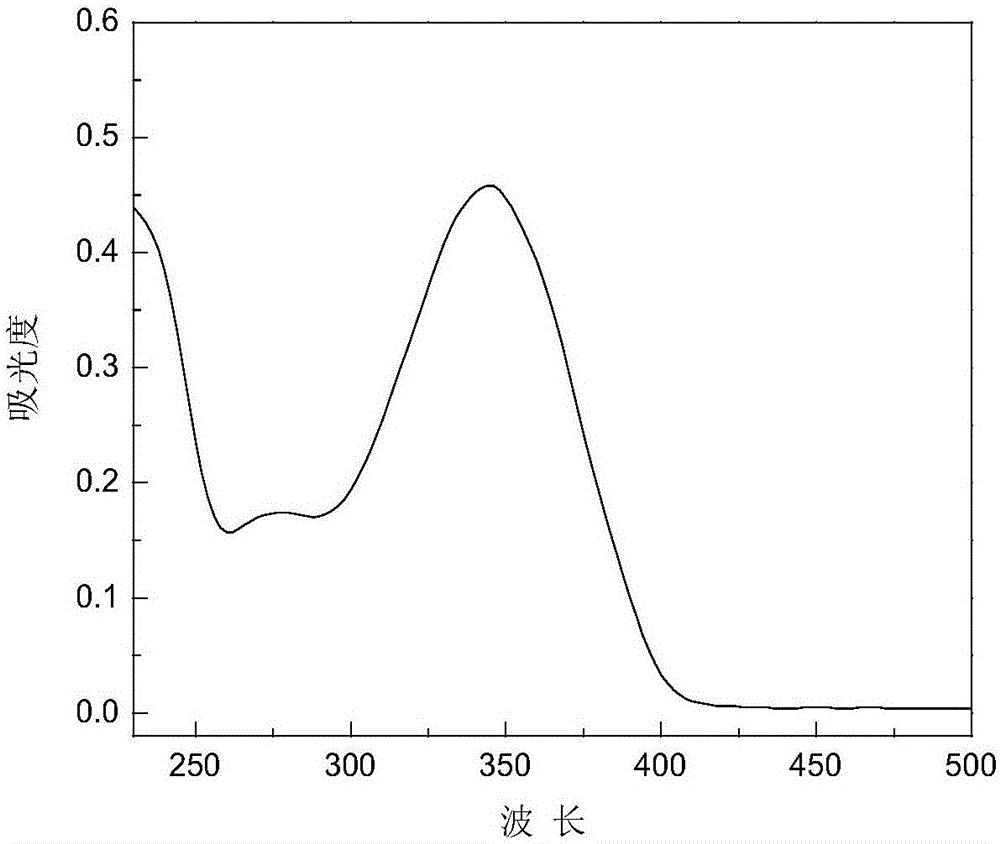

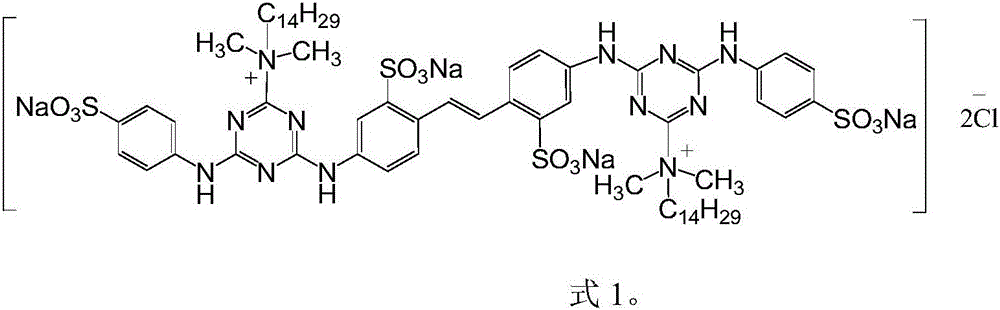

Embodiment 1

[0034] Add 20mmol cyanuric chloride to 200mL ice water, ice bath. Then dropwise add a mixture of 10mmol 4,4'-diaminostilbene-2,2'-disulfonic acid (DSD acid) and 200mL distilled water (add 20mmol Na 2 CO 3 ), stirred at 0-5°C, and reacted for 2h. Heat up to 30~40℃, add 20mmol Na 2 CO 3 . Then, a mixture of 20 mmol of tetradecyl dimethyl tertiary amine and 10 mL of dimethylformamide was added dropwise, and the reaction was carried out under temperature control for 10 h. Heat up to 80-90°C, add 20mmol p-aminobenzenesulfonic acid, add dropwise 10% Na 2 CO 3 The solution maintains the pH of the system at 8-9, and the temperature is controlled for 8 hours. Cool to room temperature, add 60 g of sodium chloride, stir, filter with suction, and dry in vacuum to obtain a water-soluble heavy calcium carbonate powder fluorescent whitening agent with a yield of 90%.

Embodiment 2

[0036] Add 19mmol cyanuric chloride to 250mL ice water, ice bath. Then dropwise add a mixture of 11mmol 4,4'-diaminostilbene-2,2'-disulfonic acid (DSD acid) and 195mL distilled water (add 20mmol Na 2 CO 3 ), stirred at 0-5°C, and reacted for 2h. Heat up to 30~40℃, add 20mmol Na 2 CO 3 . Then, a mixture of 21 mmol of tetradecyl dimethyl tertiary amine and 9 mL of dimethylformamide was added dropwise, and the reaction was carried out under temperature control for 10 h. Heat up to 80-90°C, add 22mmol p-aminobenzenesulfonic acid, add dropwise 10% Na 2 CO 3 The solution maintains the pH of the system at 8-9, and the temperature is controlled for 8 hours. Cool to room temperature, add 60 g of sodium chloride, stir, filter with suction, and dry in vacuum to obtain a water-soluble heavy calcium carbonate powder fluorescent whitening agent with a yield of 88%.

Embodiment 3

[0038] Add 21mmol cyanuric chloride to 225mL ice water, ice bath. Then dropwise add a mixture of 9mmol 4,4'-diaminostilbene-2,2'-disulfonic acid (DSD acid) and 205mL distilled water (add 20mmol Na 2 CO 3 ), stirred at 0-5°C, and reacted for 2h. Heat up to 30~40℃, add 20mmol Na 2 CO 3 . Then, a mixture of 18 mmol of tetradecyl dimethyl tertiary amine and 11 mL of dimethylformamide was added dropwise, and the reaction was carried out under temperature control for 10 h. Heat up to 80-90°C, add 18mmol p-aminobenzenesulfonic acid, drop 10% Na 2 CO 3 The solution maintains the pH of the system at 8-9, and the temperature is controlled for 8 hours. Cool to room temperature, add 60 g of sodium chloride, stir, filter with suction, and dry in vacuum to obtain a water-soluble ground calcium carbonate powder fluorescent whitening agent with a yield of 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com