A kind of synthetic method and application of cationic modified gamma-polyglutamic acid

A technology of polyglutamic acid and synthesis method, which is applied in the field of water treatment, can solve the problems of carcinogenicity, aggravation, and mutagenesis, and achieve the effect of promoting flocculation and sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

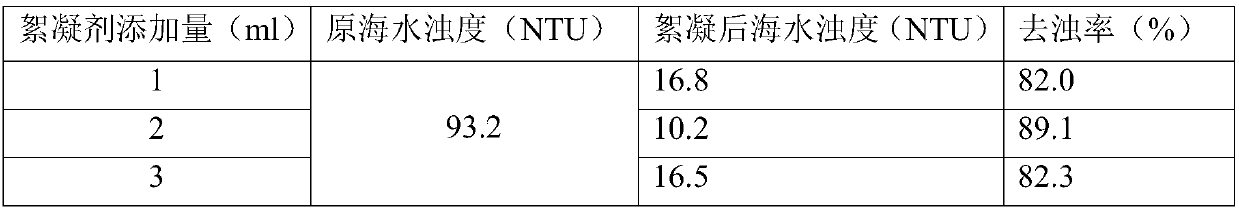

Embodiment 1

[0026] The nucleophilic substitution reaction between γ-polyglutamic acid and 3-chloro-2-hydroxypropyltrimethylammonium chloride occurs, NaOH is used as a catalyst, and the reaction is carried out in water phase.

[0027] Synthesis of Cationic Modified γ-Polyglutamic Acid

[0028] Weigh 1g of γ-polyglutamic acid and add 10ml of distilled water into a 250ml round bottom flask, and stir evenly.

[0029] Weigh 20.26g of 3-chloro-2-hydroxypropyltrimethylammonium chloride solution (65% aqueous solution) (containing 0.07mol 3-chloro-2-hydroxypropyltrimethylammonium chloride) and place it in a beaker, spare.

[0030] Weigh 0.091mol (3.64g) of NaOH and add 10ml of water to dissolve in a beaker. spare.

[0031] Fix the round-bottomed flask dissolved in γ-polyglutamic acid aqueous solution in a collector-type constant temperature heating magnetic stirrer, the reaction temperature is 50°C, swell for 1 hour, and then use a dropper to drop the etherification agent for 5 minutes. After 5...

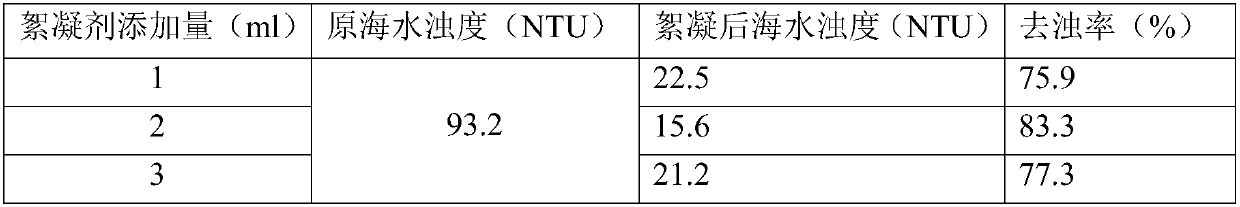

Embodiment 2

[0037] The nucleophilic substitution reaction between γ-polyglutamic acid and 3-chloro-2-hydroxypropyltrimethylammonium chloride occurs, NaOH is used as a catalyst, and the reaction is carried out in water phase.

[0038] Synthesis of Cationic Modified γ-Polyglutamic Acid

[0039] Weigh 1g of γ-polyglutamic acid and add 10ml of distilled water into a 250ml round bottom flask, and stir evenly.

[0040] Weigh 0.04mol (11.57g) of 3-chloro-2-hydroxypropyltrimethylammonium chloride (65% aqueous solution) into a beaker and set aside.

[0041] Weigh 0.052mol (2.08g) of NaOH and add 10ml of water to dissolve in a beaker. spare.

[0042] Fix the round-bottomed flask dissolved in γ-polyglutamic acid aqueous solution in a collector-type constant temperature heating magnetic stirrer, the reaction temperature is 50°C, swell for 1 hour, and then use a dropper to drop the etherification agent for 5 minutes. After 5 minutes, Add the NaOH solution dropwise in another 3 minutes, and react fo...

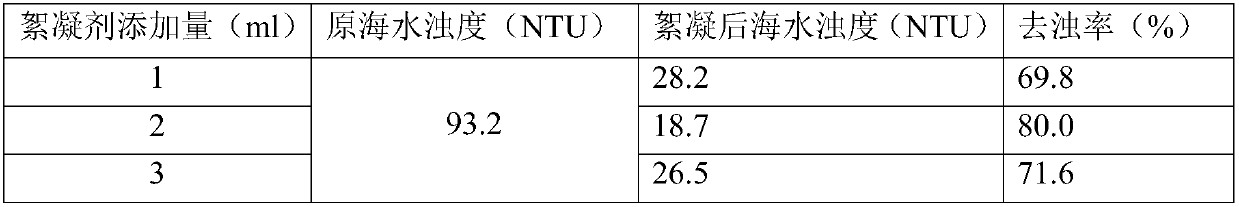

Embodiment 3

[0049] The nucleophilic substitution reaction between γ-polyglutamic acid and 3-chloro-2-hydroxypropyltrimethylammonium chloride occurs, NaOH is used as a catalyst, and the reaction is carried out in water phase.

[0050] Synthesis of Cationic Modified γ-Polyglutamic Acid

[0051] Weigh 1g of γ-polyglutamic acid and add 10ml of distilled water into a 250ml round bottom flask, and stir evenly.

[0052] Weigh 0.07mol (20.26g) of 3-chloro-2-hydroxypropyltrimethylammonium chloride (65% aqueous solution) into a beaker and set aside.

[0053] Weigh 0.091mol (3.64g) of NaOH and add 10ml of water to dissolve in a beaker. spare.

[0054] Fix the round-bottomed flask dissolved in γ-polyglutamic acid aqueous solution in a collector-type constant temperature heating magnetic stirrer, the reaction temperature is 50°C, swell for 1 hour, and then use a dropper to drop the etherification agent for 5 minutes. After 5 minutes, Add NaOH solution dropwise in 3 minutes and react for 3 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com