High-rigidity oxidation-resistant polypropylene synergistically regulated and controlled by molecular sieve/phosphate sodium salt and preparation method thereof

A technology of sodium phosphate and polypropylene is applied in the fields of polypropylene composite material and its preparation, high-rigidity oxidation-resistant polypropylene and its preparation, which can solve problems such as high price and affect toughness, and achieve low production cost and high thermal and oxygen stability. The effect of improving the stability of thermo-oxidative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

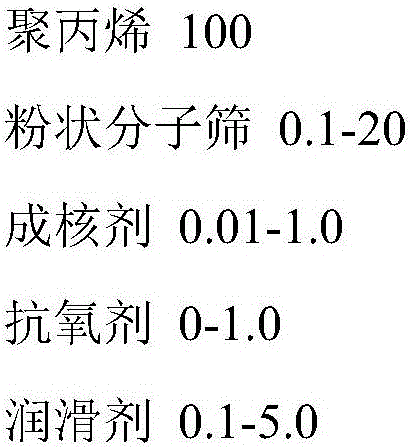

Method used

Image

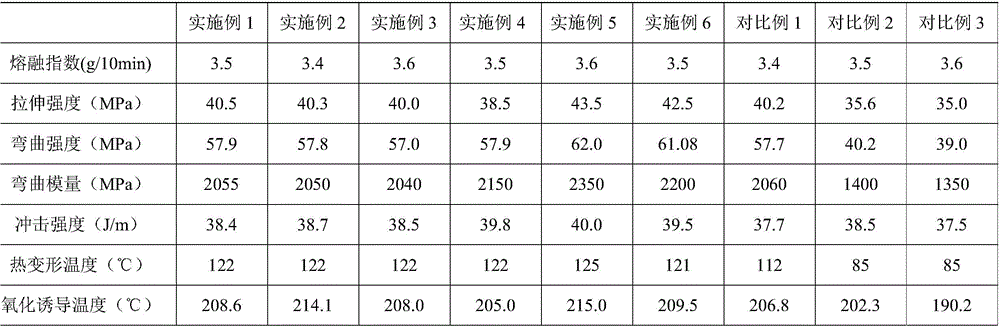

Examples

Embodiment 1

[0039] The raw materials used are as follows: 100 parts of homopolypropylene with a melt flow rate of 0.5-20g / min (test conditions: 230°C, 2.16Kg); 0.04 parts of 13X molecular sieve with a particle size of 3-4 microns, Shanghai Jiuzhou Chemical Co., Ltd. Company; 0.16 parts of NA-40 nucleating agent, Shanghai Shengpan New Material Technology Co., Ltd.; 0.05 part of Irganox1010 antioxidant, BASF Company; 0.05 part of Irgafos168 auxiliary antioxidant, BASF Company; 0.05 part of calcium stearate.

[0040] First, mix the resin and various additives in a high-speed mixer for 5-10 minutes, and then carry out melt extrusion and granulation in a twin-screw extruder at 220°C. The polypropylene particles granulated according to the above method were dried in a vacuum oven at 100° C. for 2 hours, and then the dried particles were injection-molded on an injection molding machine to prepare samples.

Embodiment 2

[0042] The amount of molecular sieve in Example 1 was changed to 0.1 part, and the amount of nucleating agent was changed to 0.1 part. All the other raw material consumptions are the same as in Example 1.

Embodiment 3

[0044] The antioxidant consumption in embodiment 1 is changed into 0. All the other raw material consumptions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com