A kind of quick-drying water-based color correction agent base material and preparation method thereof

A color-correcting agent, water-based technology, applied in the field of quick-drying water-based color-correcting agent base material and its preparation, can solve the problems of increasing production time and increasing production cost, and achieves the effect of saving construction time, fast drying speed and small odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

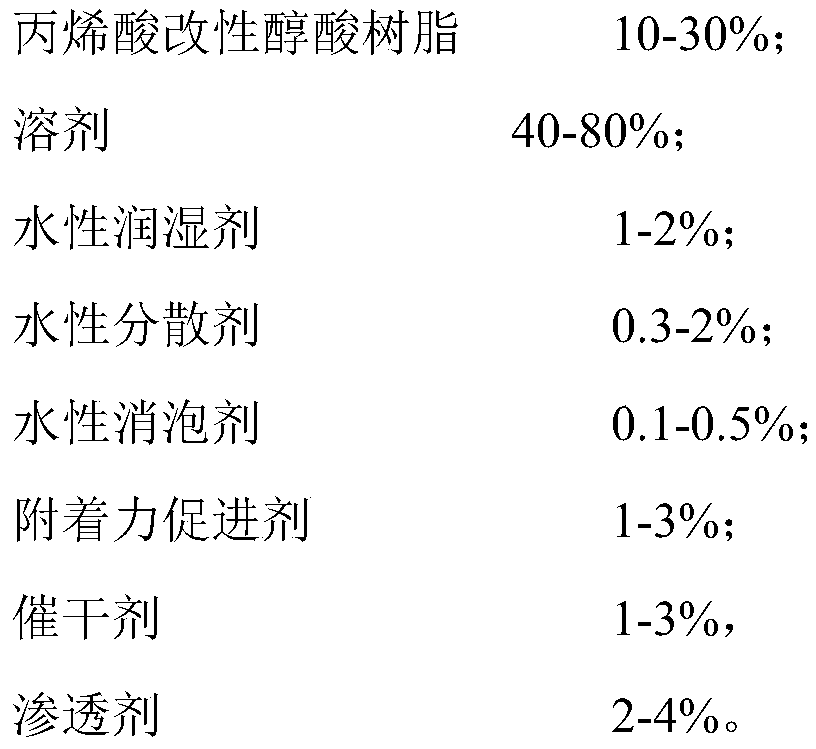

Method used

Image

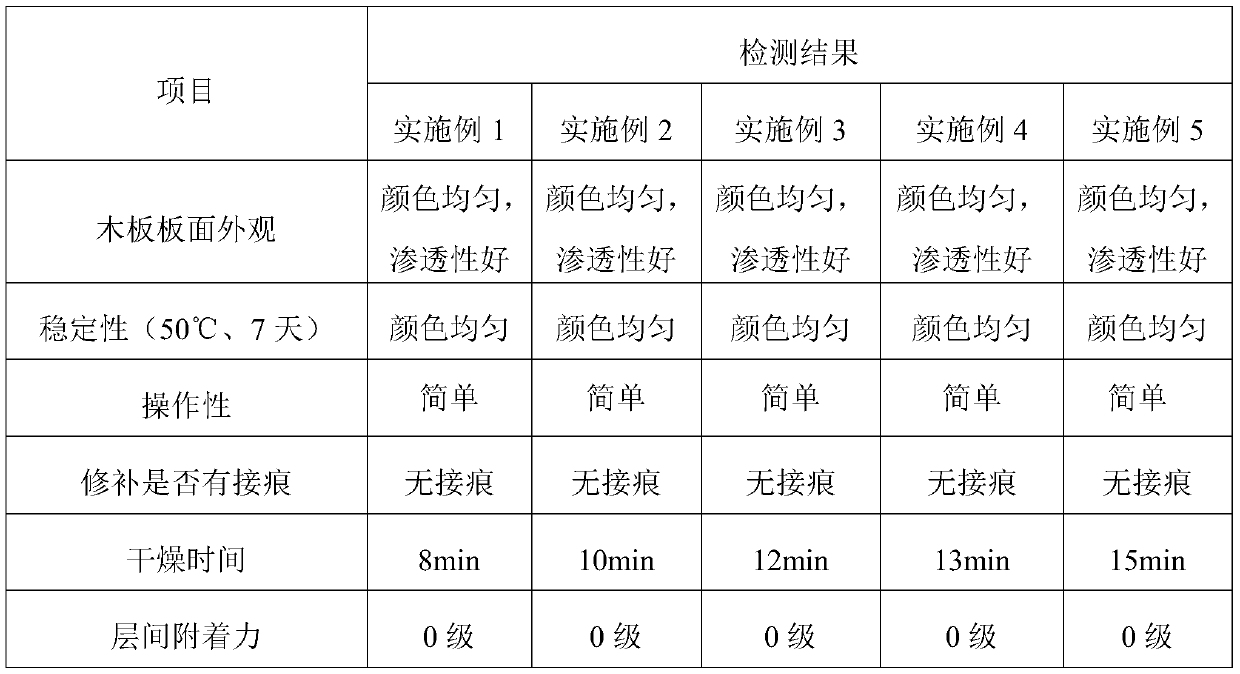

Examples

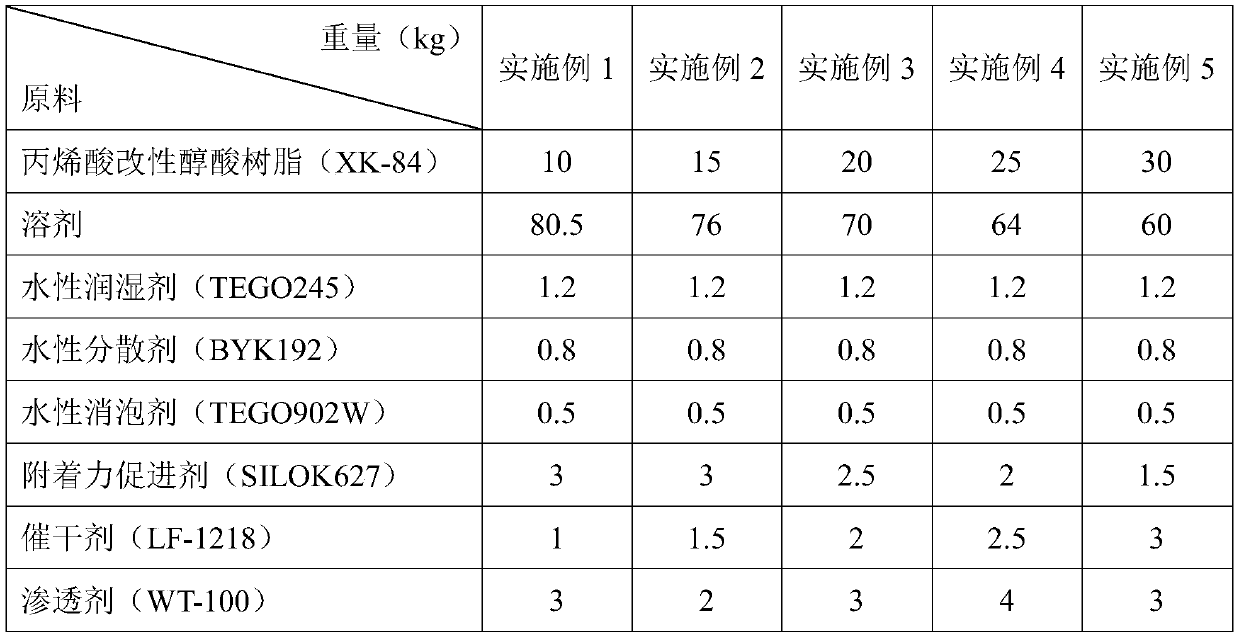

Embodiment 1

[0029] First add 10kg of DSM XK-84 acrylic modified alkyd resin into the mixer, start stirring, and control the stirring speed at 400r / min; then add 1.2kg of TEGO245 water-based wetting agent, 80.5kg of solvent, 0.8kg BYK192 water-based dispersant, 0.5kg of TEGO902W water-based defoamer and 3kg of SILOK627 adhesion promoter, stir evenly, add 1kg of LF-1218 drier, increase the stirring speed to 700r / min, disperse for 6min, and then Reduce the stirring speed to 400r / min, add 3kg of WT-100 penetrant, stir evenly, and obtain a quick-drying water-based color correction agent base material.

Embodiment 2

[0031] First add 15kg of DSM XK-84 acrylic modified alkyd resin into the mixer, start stirring, and control the stirring speed at 400r / min; then add 1.2kg of TEGO245 water-based wetting agent, 76kg of solvent, 0.8kg of BYK192 water-based dispersant, 0.5kg of TEGO902W water-based defoamer and 3kg of SILOK627 adhesion promoter, stir evenly, add 1.5kg of LF-1218 drier, increase the stirring speed to 700r / min, disperse for 7min, and then Reduce the stirring speed to 400r / min, add 2kg of WT-100 penetrant, stir evenly, and obtain a quick-drying water-based color correction agent base material.

Embodiment 3

[0033] First add 20kg of DSM XK-84 acrylic modified alkyd resin into the mixer, start stirring, and control the stirring speed at 430r / min; then add 1.2kg of TEGO245 water-based wetting agent, 70kg of solvent, 0.8kg of BYK192 water-based dispersant, 0.5kg of TEGO902W water-based defoamer and 2.5kg of SILOK627 adhesion promoter, stir evenly, add 2kg of LF-1218 drier, increase the stirring speed to 700r / min, disperse for 7min, and then Reduce the stirring speed to 430r / min, add 3kg of WT-100 penetrant, stir evenly, and obtain a quick-drying water-based color correction agent base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com