Electric net hardware fitting coated with dual-ingredient waterborne epoxy anticorrosive paint and preparation method of anticorrosive paint

A technology of water-based epoxy and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as environmental pollution, endangering construction and user health, fire hazards, etc., and achieve the effect of reducing VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

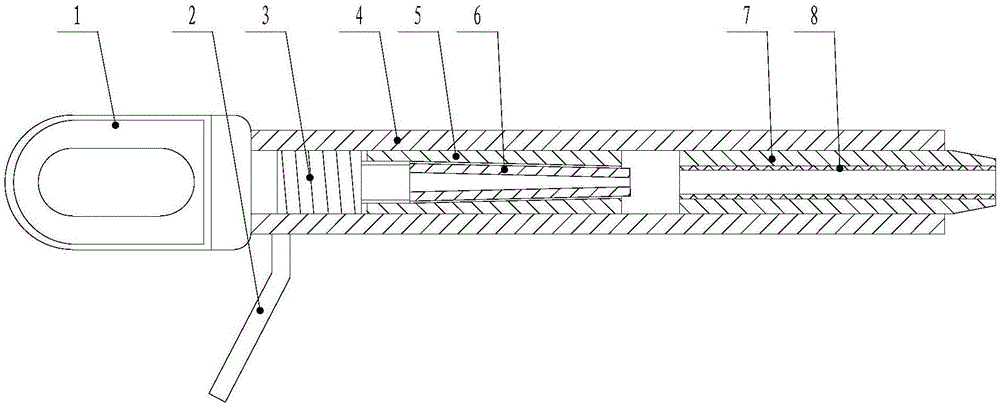

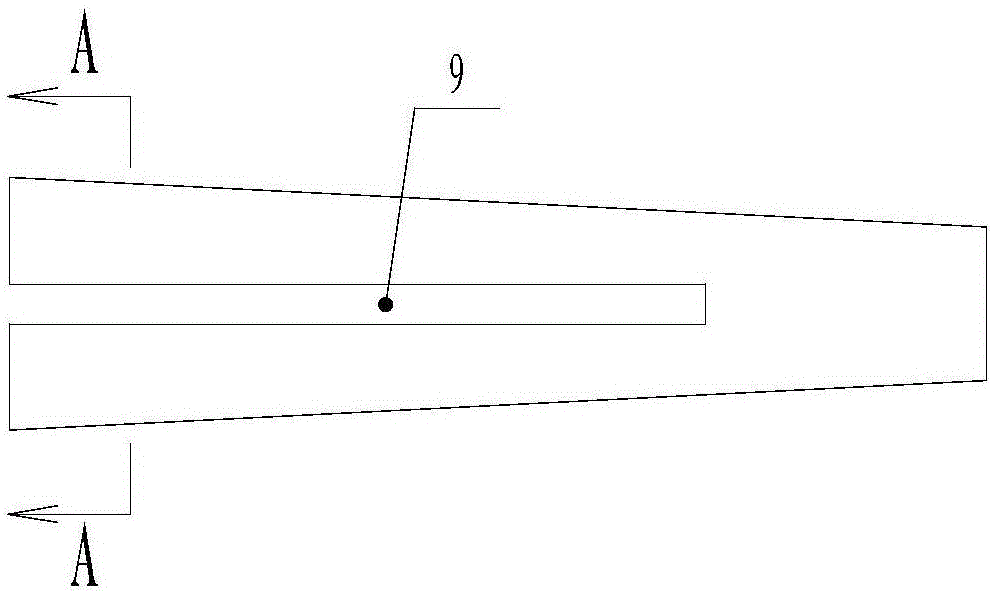

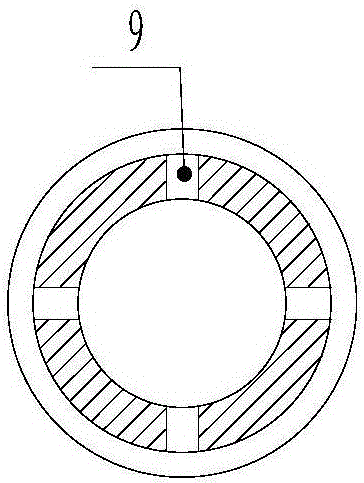

[0027] Such as Figure 1 to Figure 3 As shown, a power grid fitting coated with a two-component water-based epoxy anti-corrosion coating includes a tension clamp body 4, a steel anchor 1, a drainage plate 2, an inner liner 5, a wedge clamp 6, and an aluminum sleeve 7. The tension clamp body 4 is hollow tubular, and the anchor rod 3 at the front end of the steel anchor 1 is passed through the end of the tension clamp body 4, and is connected with the inner lining in the tension clamp body 4. The pipe 5 is internally threaded, the diversion plate 2 is fixed on the tension clamp body 4, the wedge-shaped clamp 6 is provided with a plurality of strip-shaped cutouts 9, and the wedge-shaped clamp 6 of the power grid fittings is provided with strip-shaped cutouts 9 , when the strip-shaped cutout 9 shrinks, the mandrel is firmly fixed in the inner cavity of the wedge-shaped clamp 6, and the wedge-shaped clamp 6 and the aluminum sleeve 7 are solid-fused with a planted film friction with...

Embodiment 2

[0037] A two-component water-based epoxy anti-corrosion coating for power grid hardware, comprising A component and B component, A component is composed of the following materials by weight: 20 parts of water-based modified amine epoxy curing agent, low lead content antirust pigment 16 parts, 25 parts of deionized water, 0.5 parts of wetting agent, 0.5 parts of dispersant, 0.5 parts of defoamer, 20 parts of filler, 2 parts of silane coupling agent, 2 parts of alcohol ether additives, thickening rheological agent 0.8 parts, preservative 0.5 parts, PH regulator 0.5 parts, anti-flash rust agent 0.5 parts, water-based adhesion promoter 1.2 parts;

[0038] Component B is 60 parts of water-based epoxy resin emulsion;

[0039] The A component and the B component are mixed and used according to the weight ratio A:B=3:2.

[0040] Other technical contents of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0042] A two-component water-based epoxy anti-corrosion coating for power grid hardware, comprising A component and B component, A component is composed of the following materials by weight: 15 parts of water-based modified amine epoxy curing agent, low lead content antirust pigment 16 parts, 20 parts of deionized water, 0.5 parts of wetting agent, 0.5 parts of dispersing agent, 0.5 parts of defoamer, 15 parts of filler, 2 parts of silane coupling agent, 2 parts of alcohol ether additives, thickening rheological agent 1 part, 0.5 part of preservative, 0.5 part of PH regulator, 0.5 part of anti-flash rust agent, 1 part of water-based adhesion promoter;

[0043] Component B is 75 parts of water-based epoxy resin emulsion,

[0044] The A component and the B component are mixed and used according to the weight ratio A:B=1:1.

[0045] Other technical contents of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com