Two-component decoration sealant and preparation method thereof

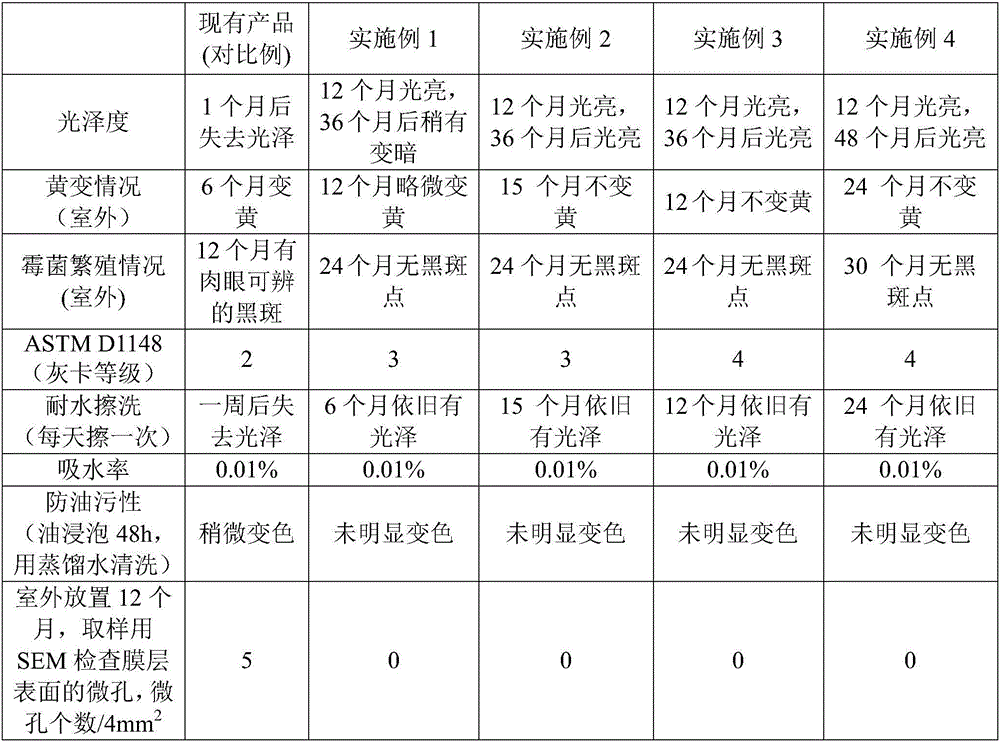

A joint-beautifying agent, a two-component technology, applied in the field of caulking agent, can solve problems such as short duration of brightness, easy yellowing after a long time, and not resistant to water scrubbing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0081] Preparation of Modified Curing Agent I: Isophorone Diamine (IPDA)

[0082] Add 30 parts by weight of E-51 epoxy resin (epoxy equivalent: 185-190g / eq) dropwise to 23 parts by weight of isophoronediamine (molecular weight: 170) within 1.5h, and control the reaction temperature to 50°C , and reacted for 2h to obtain the modified curing agent I.

preparation example 2

[0084] Preparation of Modified Curing Agent II:

[0085] Add 35 parts by weight of E-51 epoxy resin to 18 parts by weight of diaminomethylcyclohexane (molecular weight: 142) dropwise within 1.5 hours, control the reaction temperature to 50°C, and react for 2 hours to obtain modified curing agent II.

preparation example 3

[0087] Preparation of modified curing agent III:

[0088] Add 23 parts by weight of 30 parts of epoxy resin dropwise to isophorone diamine within 1.5 hours, control the reaction temperature to 50° C., react for 2 hours, and mix the mixture. Then add 1.5 parts by weight of benzyl alcohol into the mixture and stir to obtain the modified curing agent III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com