High-intensity transparent bonding agent and preparation method thereof

An adhesive and high-strength technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems such as difficult to meet the bonding requirements of parts, high and low temperature resistance, poor aging yellowing resistance, etc., to achieve High strength, excellent high and low temperature resistance and weather resistance, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 high-strength transparent adhesive and preparation method thereof

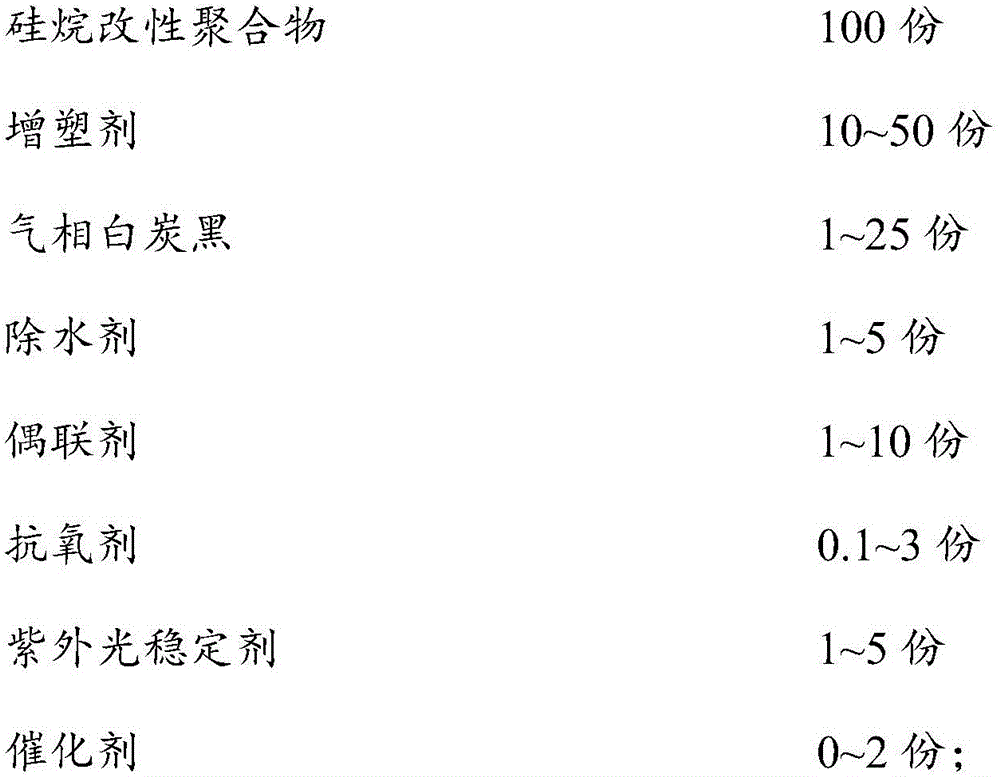

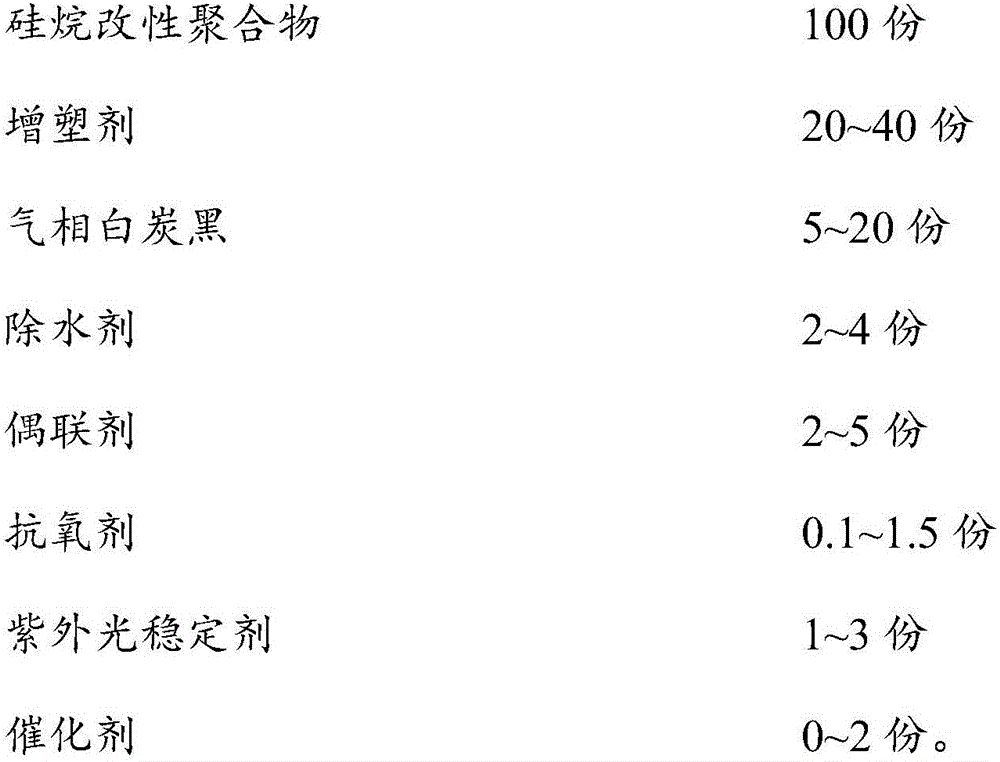

[0031] The high-strength transparent adhesive of the present embodiment is prepared from the following raw materials in parts by weight:

[0032]

[0033]

[0034] A kind of preparation method of high-strength transparent adhesive of the present embodiment comprises the steps:

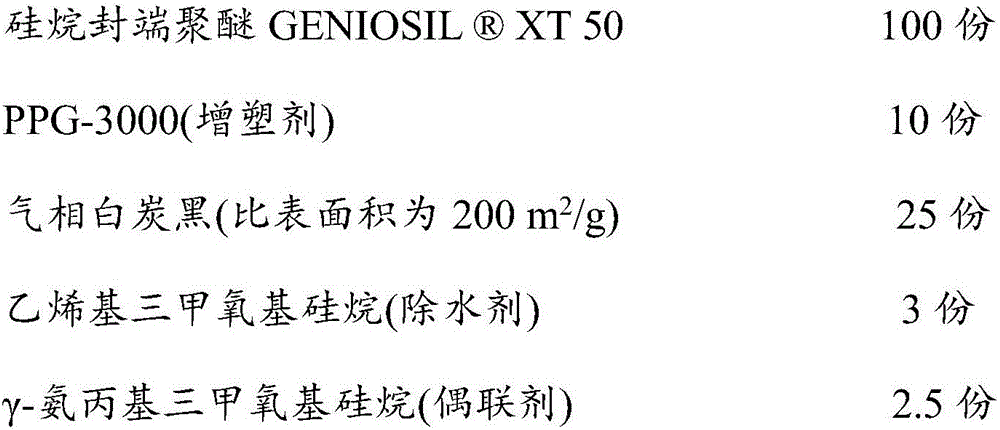

[0035] a) At room temperature, 100 parts by weight of silane-terminated polyether XT 50, 10 parts by weight PPG-3000, 25 parts by weight The specific surface area is 200m 2 / g of fumed silica is placed in a planetary mixer, and stirred at a high speed under vacuum until uniformly dispersed;

[0036] b) Add 3 parts by weight of vinyltrimethoxysilane, 2.5 parts by weight of γ-aminopropyltrimethoxysilane, 1.5 parts by weight of γ-glycidyl etheroxypropyl trimethoxysilane, 0.5 parts by weight of BASF IRGANOX1135, 1 part by weight 1 part by weight of BASFTINUVIN571, 1 part by weight of BASF TINUVIN765, 0.5 part...

Embodiment 2

[0037] Embodiment 2 high-strength transparent adhesive and preparation method thereof

[0038] The high-strength transparent adhesive of the present embodiment is prepared from the following raw materials in parts by weight:

[0039]

[0040]

[0041] A kind of preparation method of high-strength transparent adhesive of the present embodiment comprises the steps:

[0042] a) At room temperature, 100 parts by weight of silane-modified polyether KANEKA SAX400, 40 parts by weight of diisononyl phthalate, and 5 parts by weight of a specific surface area of 200m 2 / g of fumed silica is placed in a planetary mixer, and stirred at a high speed under vacuum until uniformly dispersed;

[0043] b) Add 2 parts by weight of vinyltrimethoxysilane, 3 parts by weight of γ-aminopropyltrimethoxysilane, 0.5 parts by weight of BASF IRGANOX1135, 1 part by weight of BASF TINUVIN571, and 1 part by weight of dibutyltin oxide, in a vacuum of 0.095 MPa, under the rotation speed of 200rpm, st...

Embodiment 3

[0044] Embodiment 3 high-strength transparent adhesive and preparation method thereof

[0045] The high-strength transparent adhesive of the present embodiment is prepared from the following raw materials in parts by weight:

[0046]

[0047]

[0048] The preparation method of a kind of high-strength transparent adhesive of the present embodiment comprises the following steps:

[0049] a) At room temperature, 80 parts by weight of silane-terminated polyurethane prepolymer SPUR + Y-15990, 20 parts by weight of silane-terminated polyether STP-E10, 20 parts by weight of diisononyl phthalate, 5 parts by weight of specific surface area of 200m 2 / g of fumed silica is placed in a planetary mixer, and stirred at a high speed under vacuum until uniformly dispersed;

[0050] b) Add 3 parts by weight of vinyltrimethoxysilane, 1.5 parts by weight of γ-aminopropyltrimethoxysilane, 2.5 parts by weight of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 0.5 Parts by weight of B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com