Flexible material capable of saving fuel

A technology of flexible materials and functional materials, applied in the field of energy saving and environmental protection, can solve the problems of unscientific selection of negative ion materials, indirect effect on fuel-saving cards, and less filling of negative ion materials, so as to achieve simple and feasible preparation and installation, outstanding fuel-saving effect, Significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

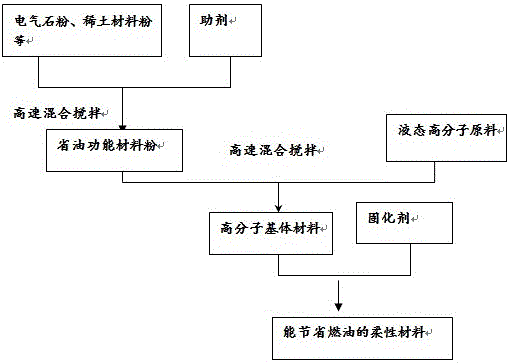

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.3 kg of tourmaline powder and rare earth material powder in a ratio of 1:1, stir and mix evenly, and add 0.03 kg of liquid coupling agent at the same time, and stop after 1 hour. Mix the above mixed powder with 2 kg of liquid neoprene base material, stir at high speed for 0.5 h, then add 0.1 kg of additives and cross-linking agents and stir at high speed for 0.1 h; molding, demoulding, and curing to obtain fuel-saving flexible materials .

[0032] Wrap the flexible material around the fuel pipeline of a Buick LaCrosse and around the fuel filler port of the fuel tank, and stick it firmly. After testing, the Buick LaCrosse's comprehensive fuel consumption (No. 93 gasoline) was 12.7L / 100km before using the fuel-saving package. After using the fuel-saving package, the Buick LaCrosse's comprehensive fuel consumption (No. 93 gasoline) was 11.0L / 100km, saving fuel. 12.1%.

Embodiment 2

[0034] Weigh 0.3 kg of tourmaline powder and rare earth material powder in a ratio of 1:1, stir and mix evenly, and add 0.03 kg of liquid coupling agent at the same time, and stop after 1 hour. Mix the above mixed powder with 2 kg of liquid polyethylene base material, stir at high speed for 0.5 h, then add 0.1 kg of additives and cross-linking agent and stir at high speed for 0.1 h; molding, demoulding, and curing to obtain fuel-saving flexible materials.

[0035] Wrap the flexible material around the fuel pipeline of a Buick LaCrosse and around the fuel filler port of the fuel tank, and stick it firmly. After testing, the Buick LaCrosse's comprehensive fuel consumption (No. 93 gasoline) was 12.7L / 100km before using the fuel-saving package. After using the fuel-saving package, the Buick LaCrosse's comprehensive fuel consumption (No. 93 gasoline) was 10.9L / 100km, saving fuel. 12.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com