A low-temperature carbonization device for carbon fiber production

A low-temperature carbonization, carbon fiber technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of carbon fiber quality decline, poor spinning quality, lack of cooling links in the carbon spinning exit section, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the following detailed description is not considered to limit the present invention.

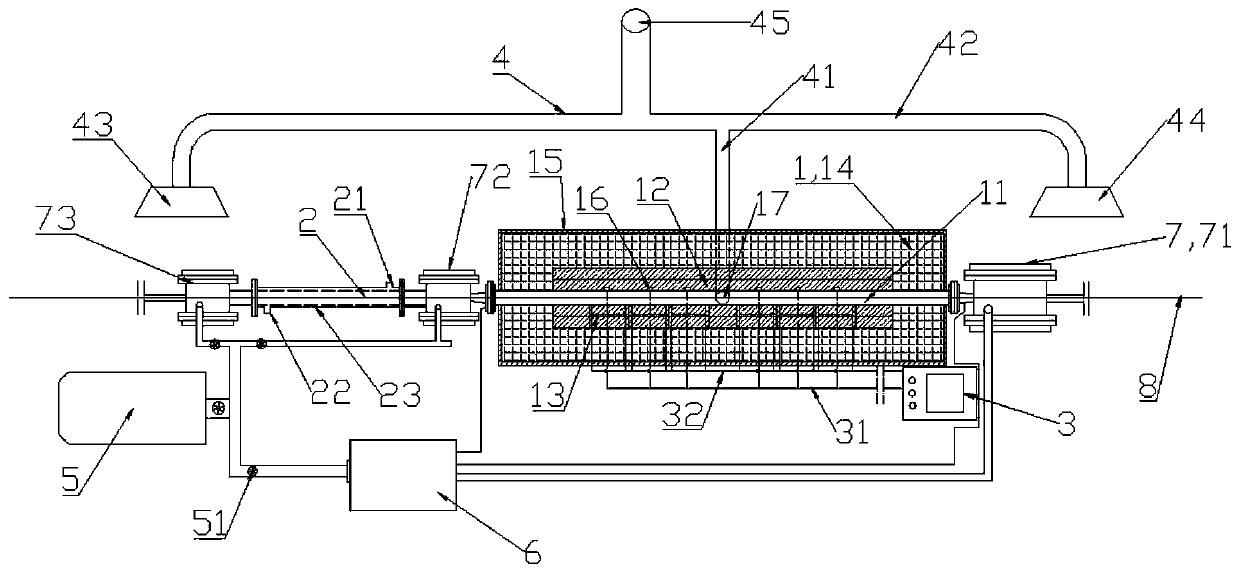

[0019] figure 1 It is a schematic diagram of the front view structure of the high-temperature carbonization device in a preferred solution of the present invention, in which the furnace body is partially cut away. From figure 1 It can be seen that the low-temperature carbonization furnace is composed of a furnace body 1, a cooling chamber 2, a temperature detection and control device 3, an exhaust system 4, a protective gas supply system 5, a protective gas heating device 6 and a sealing device 7.

[0020] Among them, the furnace body 1 consists of a furnace hearth 11 at the center, a semi-circular silicon carbide liner 12 wrapped outside the furnace body 11 , a heating device 13 and a temperature sensor 16 inside the silicon carbide liner 12 . Wrapped outside the silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com