Construction Method of Tension Formed Composite Structure Arch Bridge

A technology of combined structure and construction method, applied in arch bridges, bridge construction, bridges, etc., can solve the problems of large welding workload, many arch rib joints, large amount of brackets, etc., to achieve fast construction, improve bearing capacity, easy hoisting and The effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

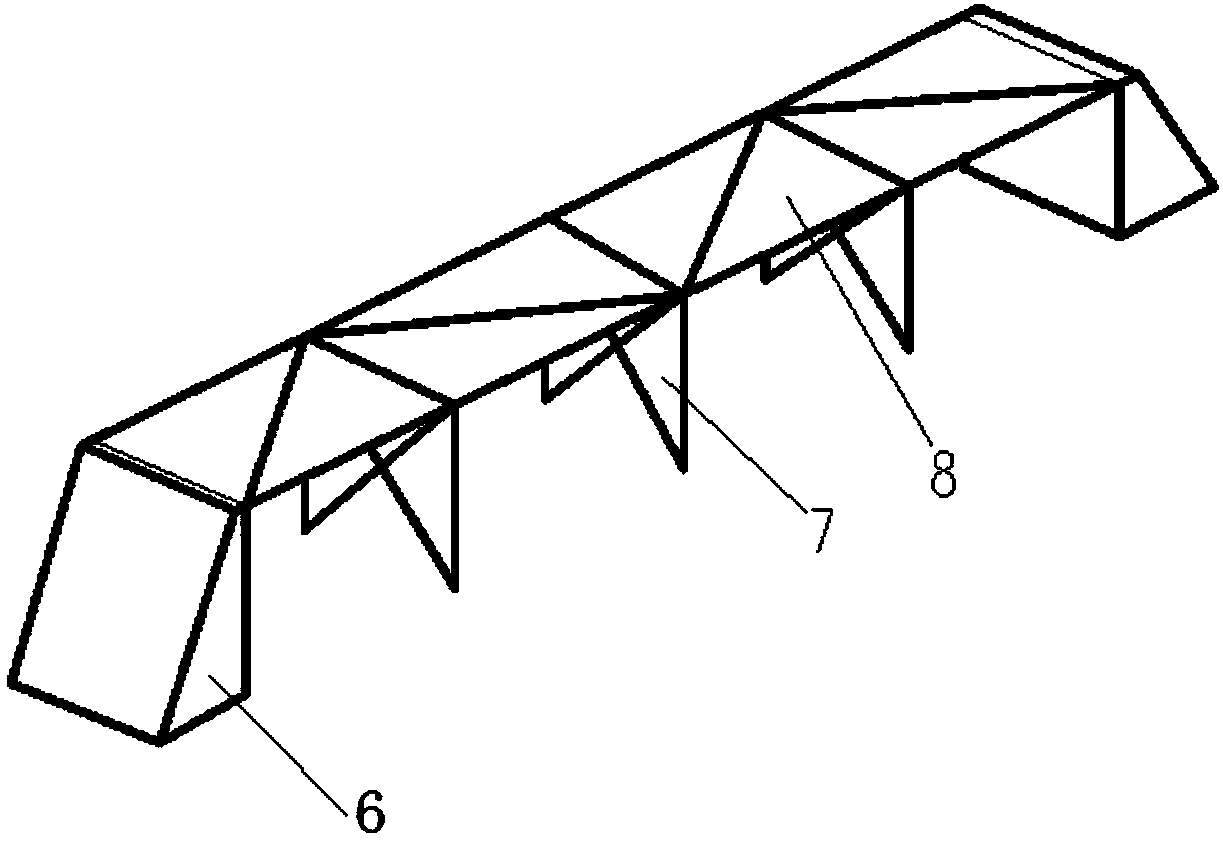

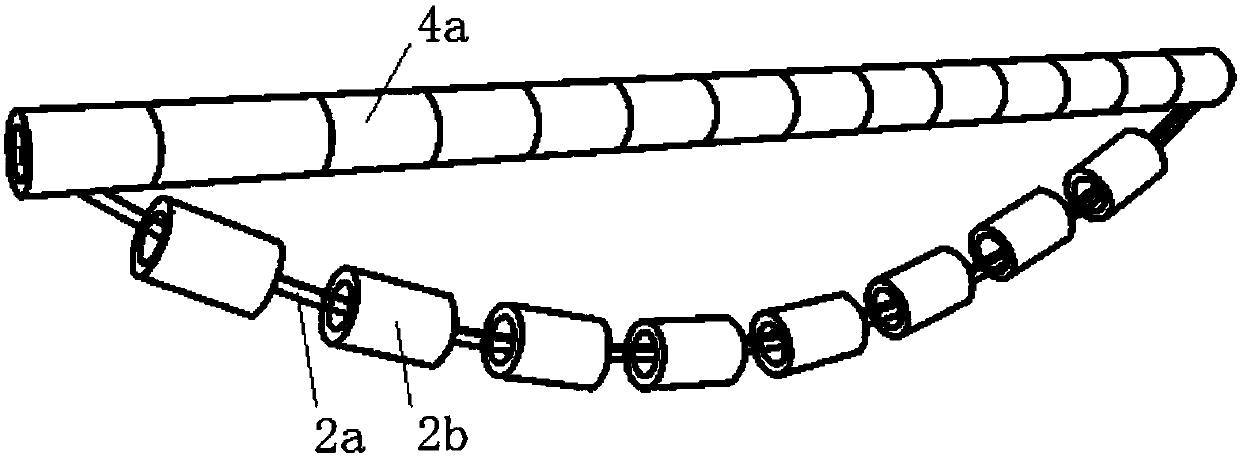

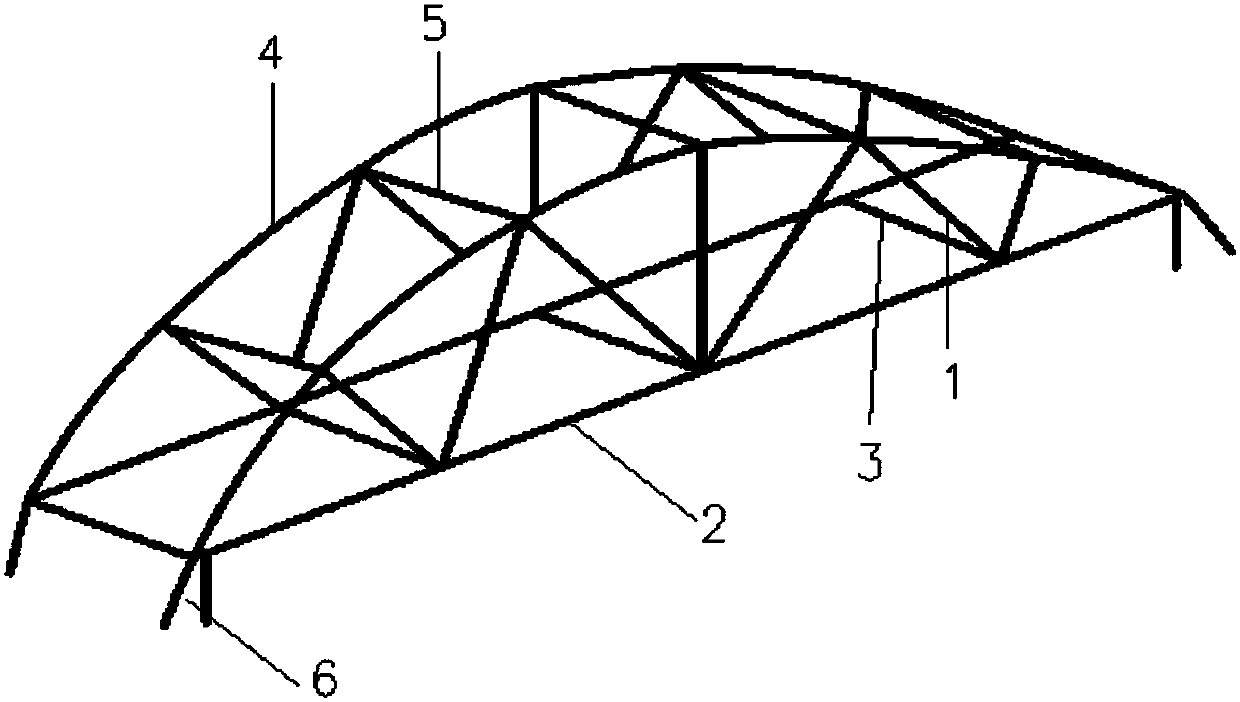

[0024] like image 3 As shown, the tension forming composite structure arch bridge of the present invention comprises at least two flat lower chords 2 parallel to each other, at least two upper chords 4 parallel to each other on the arch, and a group of transversely connected adjacent two upper chords. Cross brace 5, a set of web bars (also called suspenders) connected between the upper and lower chords on the same side 1, a set of beams 3 connected between two adjacent lower chords; After laying, it becomes a bridge deck for pedestrians and vehicles. The lower chord is composed of a group of lower chord tubes 2b sequentially threaded on the lower chord steel cables 2a, and adjacent lower chord tubes are connected by flange bolts. The upper chord is welded sequentially by the upper chord tube 4a. The upper chord can be a whole tube, but usually the span of the bridge is relatively large, and several tubes need to be welded together. Micro-expansion mortar or concrete is pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com