Steel Concrete Composite Bridge Deck and Its Construction Method

A construction method and composite bridge technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of long construction period, difficult construction, heavy weight, etc., and achieve short construction period, short construction method period and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

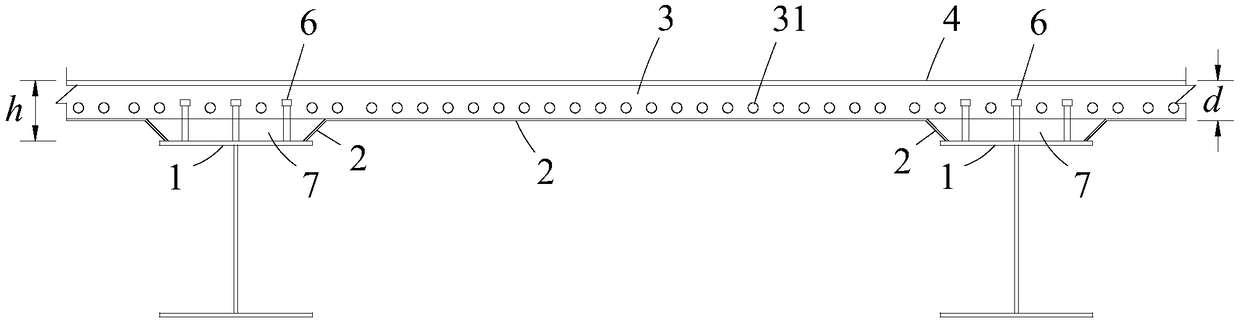

[0049] Such as Figure 1-6 As shown, a steel-concrete composite bridge deck includes:

[0050] The bottom steel plate 2 is set on the steel lattice beam 1 composed of longitudinal beams and cross beams. The bottom steel plate 2 located in the supporting area 7 of the steel lattice beam 1 is a curved shape adapted to the supporting outer wall. The thickness of the bottom steel plate 2 is 8-10mm;

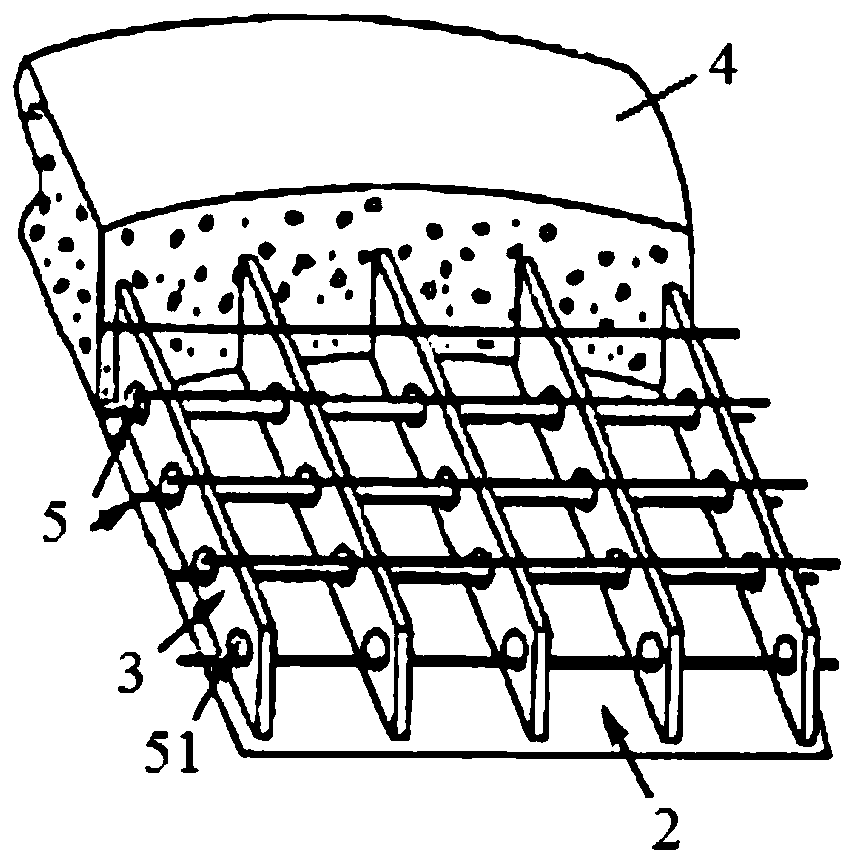

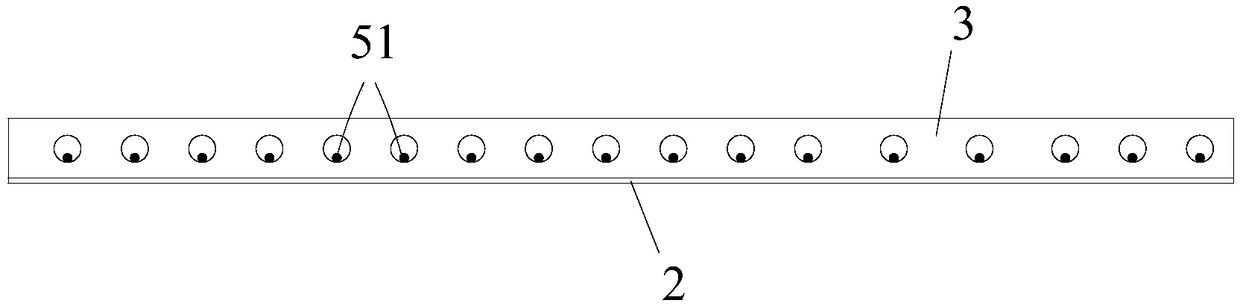

[0051] Several shear plates 3 are vertically connected on the bottom steel plate 2;

[0052] The concrete layer 4 contains the steel mesh 5 passing through the shear plate 3, the concrete layer 4 is poured on the bottom steel plate 2, and covers the shear plate 3 and the steel mesh 5;

[0053] The thickness d of the combined bridge deck is 10-15cm.

[0054] All the above-mentioned shear plates 3 are provided with several holes 31 , and the concrete layer 4 contains transverse steel bars 51 which can pass through the shear plates 3 transversely. By arranging holes 31 on the shear p...

Embodiment 2

[0070] The present invention also provides a construction method for a steel-concrete composite bridge deck, comprising the following steps:

[0071] Step 1, welding the shear plates 3, all the shear plates 3 are vertically welded on the bottom steel plate 2 in the factory, so that all the shear plates 3 are equidistantly arranged in parallel with each other along the longitudinal direction of the lattice beam;

[0072] Step 2. Weld the bottom steel plate 2, transport the bottom steel plate 2 to the construction site, lay the bottom steel plate 2 on the steel lattice beam 1, and weld and fix it on the beam or longitudinal beam. When it is located in the supporting area 7 of the steel lattice beam 1 , the bottom steel plate 2 is bent and attached to the outer wall of the supporting area 7 and fixed by welding;

[0073] Step 3, pouring the concrete layer 4, binding the steel mesh 5 between the shear plates 3, the transverse reinforcement 51 of the steel mesh 5 passes through eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com