Construction method of unsealed concrete combined cofferdam under rock geological conditions

A technology of back-sealing concrete and geological conditions, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as difficulties in inserting steel pipe pile cofferdams, instability of cofferdam structural systems, failure to meet force requirements, etc., to reduce construction difficulty and engineering quantity, low construction difficulty and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, construction method of the present invention is described in more detail.

[0026] The construction method of the unsealed concrete combined cofferdam under the geological condition of the rock formation of the present invention comprises the following specific steps:

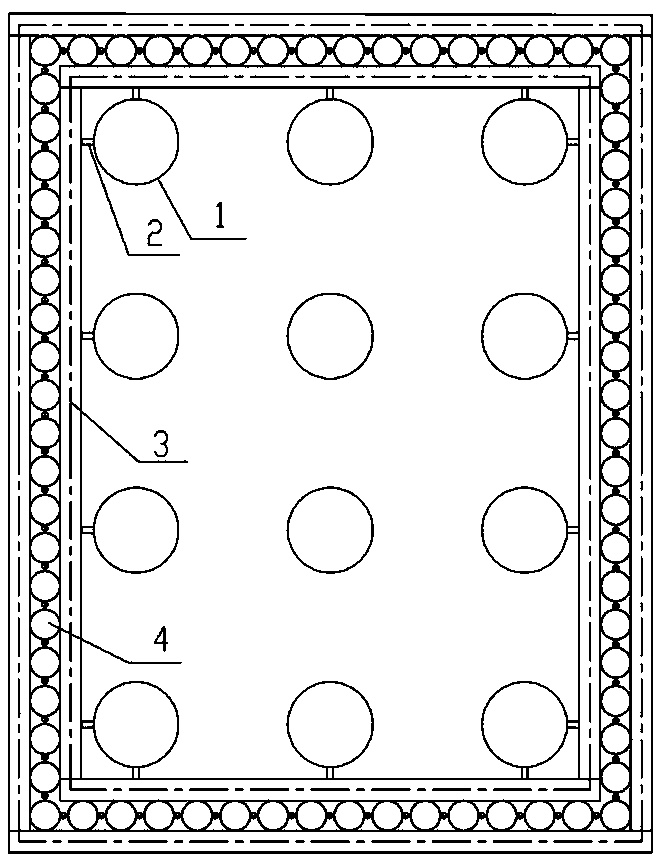

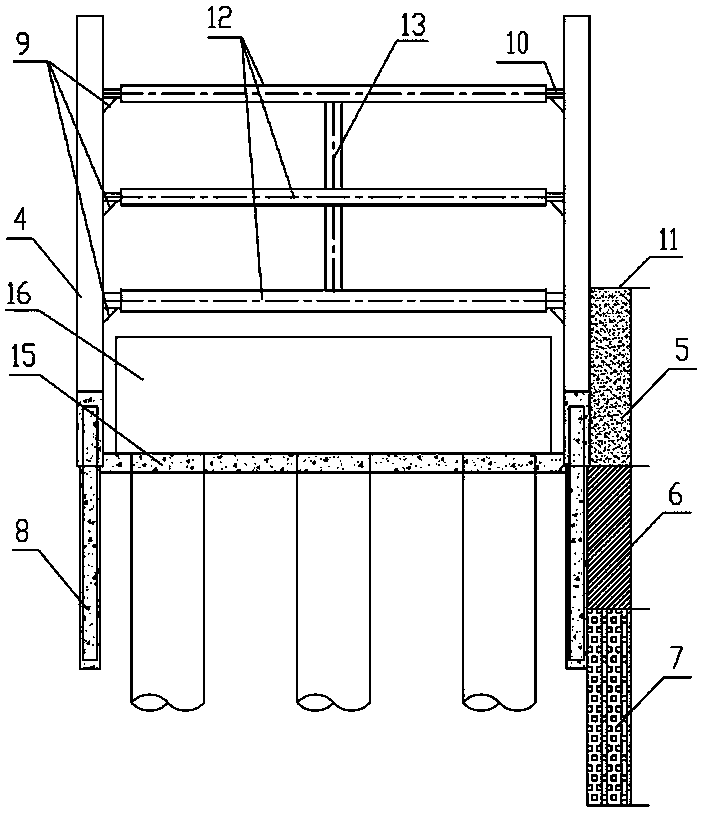

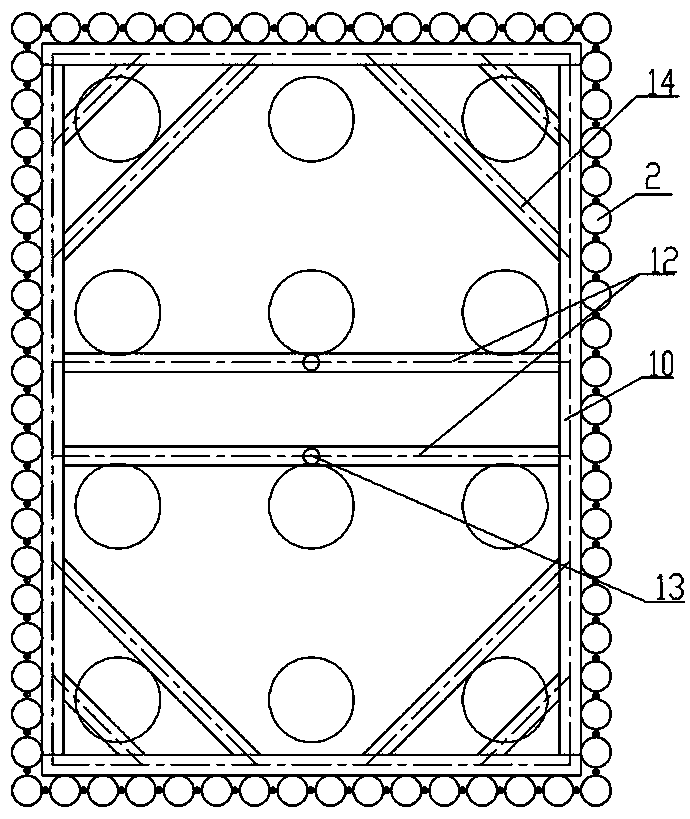

[0027] The first step is to use the crawler crane stationed on the trestle bridge to insert and drill the steel casing, and set up the drilling platform to construct the pile foundation of the main pier. After the construction of the pile foundation of the main pier is completed, the drilling platform is removed; Weld the support piece 2 on the outer surface of the steel casing 1, weld the rectangular guide frame 3 on the support piece 2, use the guide frame 3 to limit the position of the locking steel pipe pile to be inserted, and ensure the vertical direction of the locking steel pipe pile. undercutting, such as figure 1 As shown; the steel casing 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com