Two-way prestressing semicircular steel plate online flawless stabilizing concrete cylinder method

A reinforced concrete and prestressed technology, applied in the direction of building maintenance, construction, building structure, etc., can solve the problem of asynchronous stress between the old and new parts, poor stress of the reinforced specimen, and poor overall stress of the reinforced specimen, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative example 1

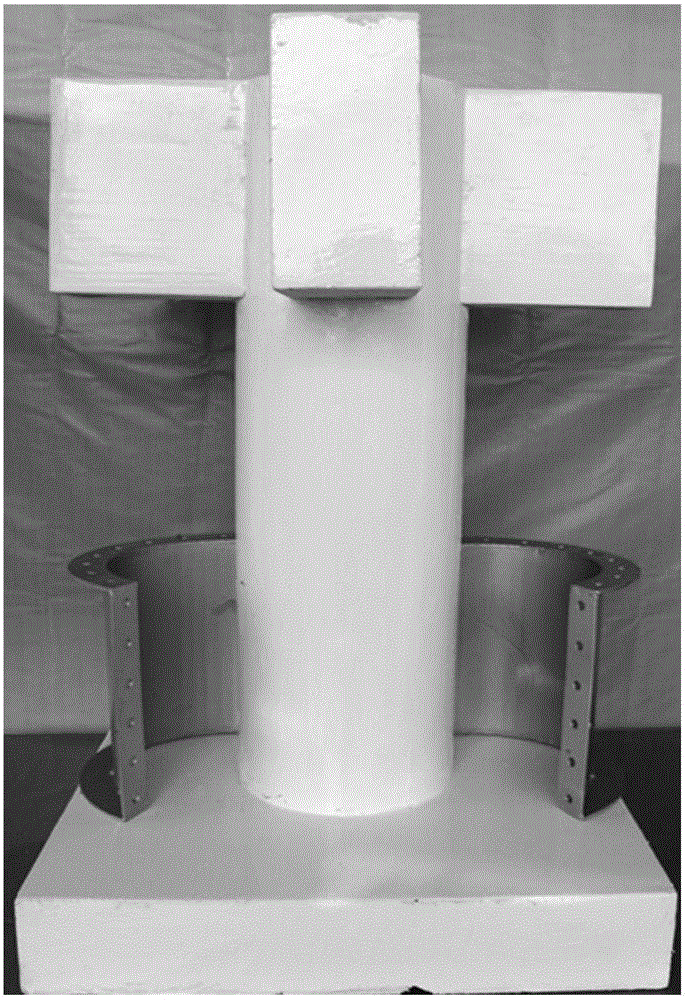

[0124] See attached Image 6 , Reinforce the outer diameter of the column to d=700mm, open holes in the original column, and implant radiation steel bars 12 steel bars, welded at the ends of the radial steel bars Ring stirrups, the spacing of the stirrups can be extended to s 1 =200mm, 12 longitudinal reinforcements for reinforcement C30 is also used for post-adding concrete. At this time, the parameters of the new column are as follows (attached Image 6 ):

[0125] The parameters of the new bar are: f c =14.3N / mm 2 , f cy =20.1N / mm 2 ; f yv =300N / mm 2 ; f ys =400N / mm 2 ; A s3 —The cross-sectional area of all the longitudinal bars of the original column under compression, A s3 =1884mm 2 ; f yt —Standard value of yield strength of welded stirrup, f yt =335N / mm 2 . d' cor =700-2×30=640mm, Cross-sectional area of a single stirrup, A' s2 =A s2 =113.1mm 2 , the longitudinal spacing of stirrups s = 200mm, the converted cross-sectional area of weld...

Embodiment approach 3

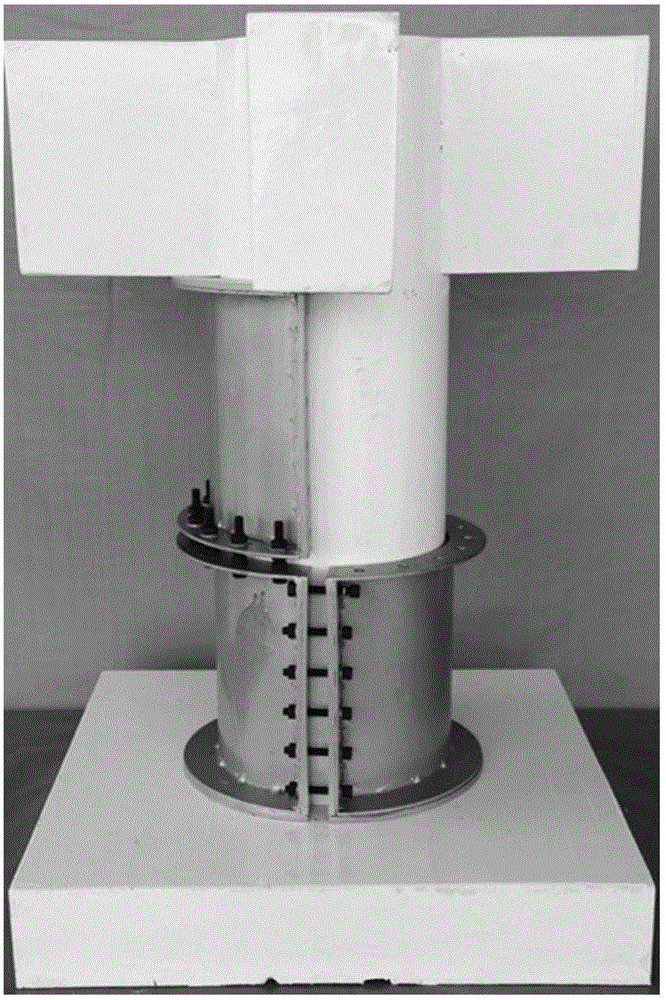

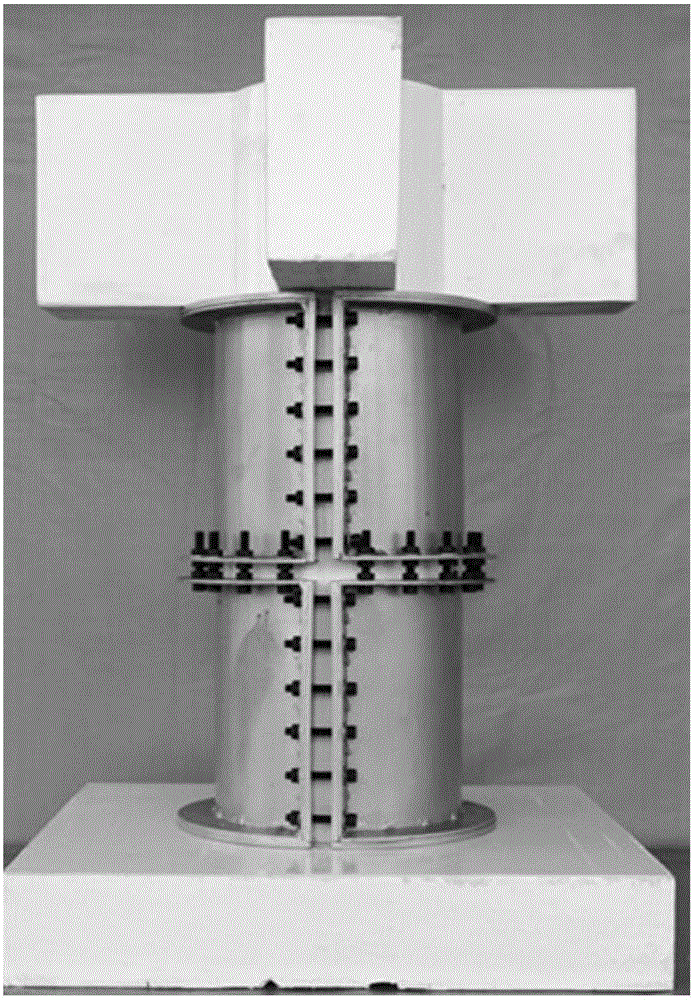

[0221] 3.3 Embodiment scheme 3 (both hoop prestress and axial prestress are added, and the hoop force is the same as scheme 2)

[0222] The semicircular steel plate is prestressed in the axial direction of the concrete column until the steel cylinder column formed by the semicircular steel plate reaches the critical axial pressure of the column or the yield strength of the steel plate, and the prestress is applied in the circumferential direction to make the semicircular steel plate reach the yield strength.

[0223] After the prestressed semi-circular steel plates are closed to reinforce the concrete column, the steel cylinder formed by the semi-circular steel plates may be unstable. The thickness of the steel plate is 10mm, the inner diameter of the steel cylinder d=500mm, the outer diameter D=520mm, and its cross-sectional area A s1 =πdt=3.14×500×10=15700mm 2 , Section moment of inertia Ⅰ=520855350mm 2 , the radius of inertia r=182.14mm for the cross section of the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com