Automobile tail gas purification treatment device

A technology for purification treatment and automobile exhaust, which is applied in the direction of exhaust treatment, exhaust device, noise reduction device, etc., and can solve the problems of non-existence and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

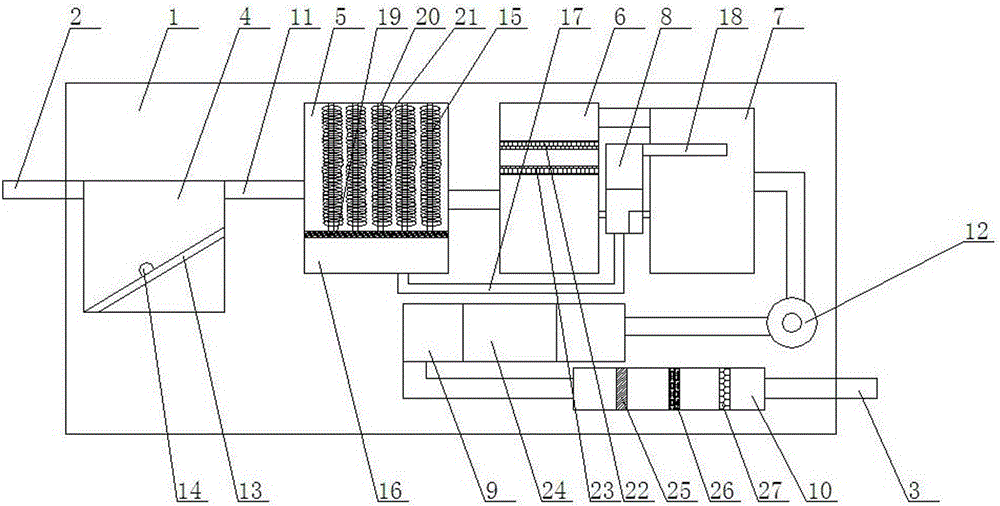

[0020] Such as figure 1 As shown, a kind of automobile exhaust purification treatment device comprises purification treatment box 1, air inlet pipe 2, exhaust pipe 3, and described air intake pipe 2 is installed at the upper left end of purification treatment box 1, and described exhaust pipe 3 is installed in the purification treatment Box 1 lower right end; said purification treatment box 1 internal device combustion chamber 4, condensation chamber 5, solid particle filter chamber 6, spray dedusting chamber 7, spray device 8, pre-processing chamber 9, post-processing chamber 10; said combustion chamber 4. Connect the condensation chamber 5 through the vent pipe 11, the condensation chamber 5 is connected to the solid particle filter chamber 6 through the vent pipe 11, the solid particle filter chamber 6 is connected to the spray dust removal chamber 7 through the vent pipe 11, and the spray dust removal chamber 7 passes through A ventilation pipe 11 with a suction fan 12 is ...

Embodiment 2

[0022] Such as figure 1 As shown, a fireproof board 13 and an electric spark plug 14 are arranged inside the combustion chamber 4 , and the electric spark plug 14 is installed on the fireproof board 13 .

Embodiment 3

[0024] Such as figure 1 As shown, the inner upper end of the condensation chamber 5 is provided with a heat exchange device 15, and the inner bottom end is provided with a liquid collection tank 16. Connect the spray dust chamber 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com