Magnetic fluid double suspension driving and driven radial bearing

A radial bearing, active and passive technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problem of low bearing capacity, and achieve the effect of improving bearing capacity, reducing temperature rise and thermal deformation, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

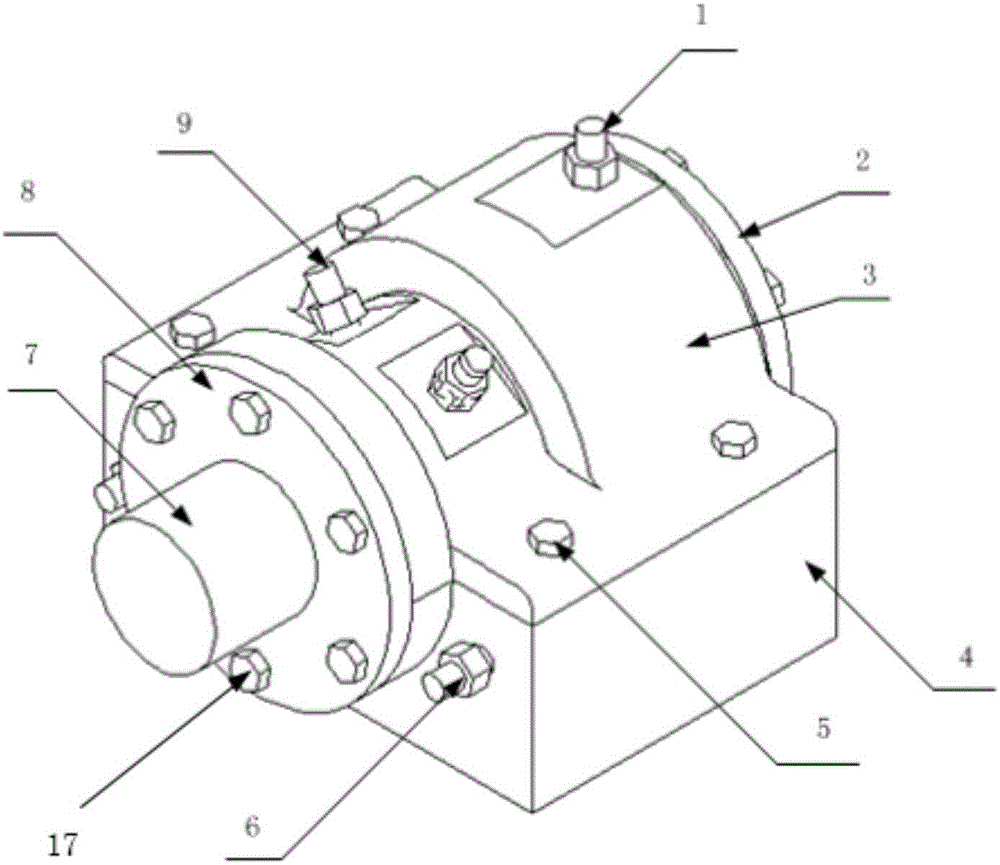

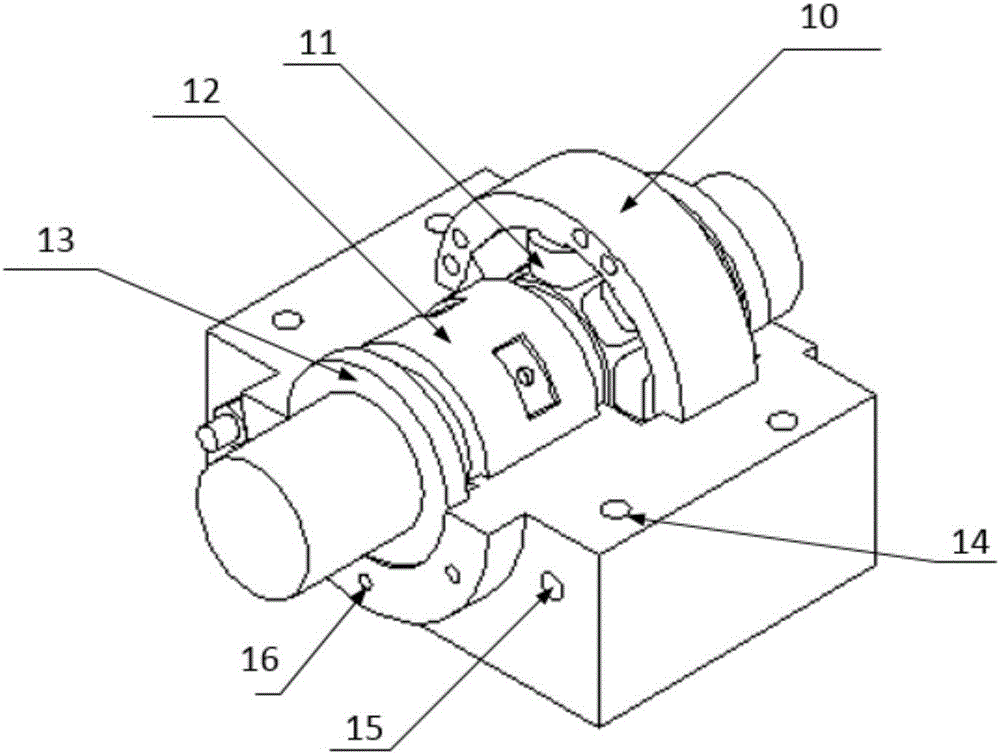

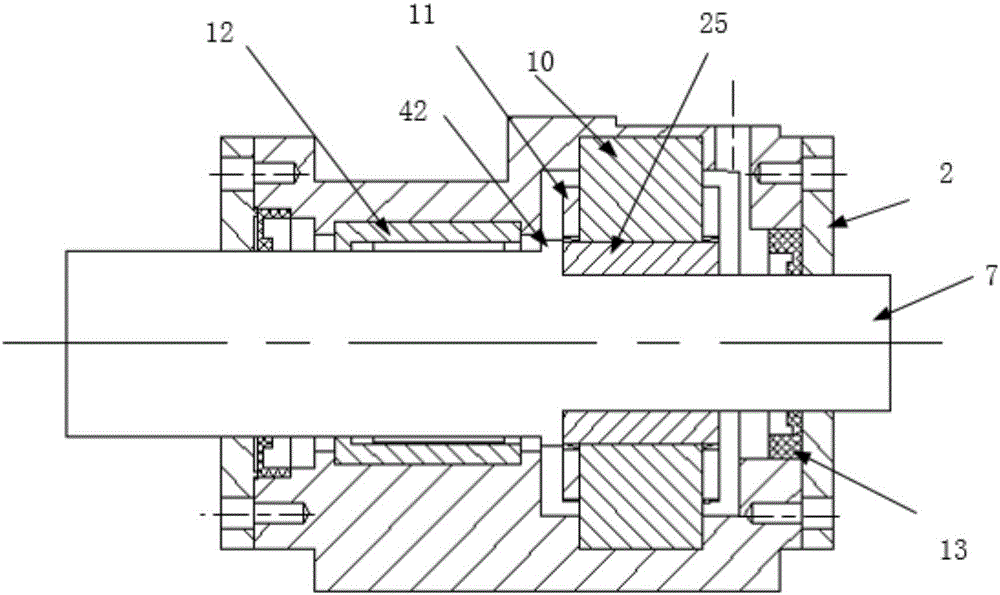

[0017] A magnetic fluid double suspension active and passive radial bearing according to an embodiment of the present invention includes two supporting systems of electromagnetic suspension and hydrostatic pressure. Such as Figure 1-7 As shown, the static pressure support system is mainly composed of the rotary shaft 7 and the hydrostatic support pad 12 . A gap of 30 to 50 μm is formed between the static pressure back-up pad 12 and the rotary shaft 7 . The electromagnetic levitation support system is mainly composed of a stator 10, an enameled wire 11, a magnetic sleeve 25, and a rotary shaft 7. The rotary shaft 7 and the magnetic sleeve 25 are interference fit.

[0018] The bearing base is processed with an annular groove 40 and an annular groove 41 . The annular groove 40 is used to fix the stator 10 . The stator 10 is made of laminated multi-layer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com