System of utilizing liquid nitrogen wash to produce syngas for synthetic ammonia and LNG

A technology for raw material gas and synthetic ammonia is applied in the field of systems for producing synthetic ammonia raw material gas and LNG, which can solve the problems of shortage, large amount of time and energy, and achieve the effect of ensuring stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

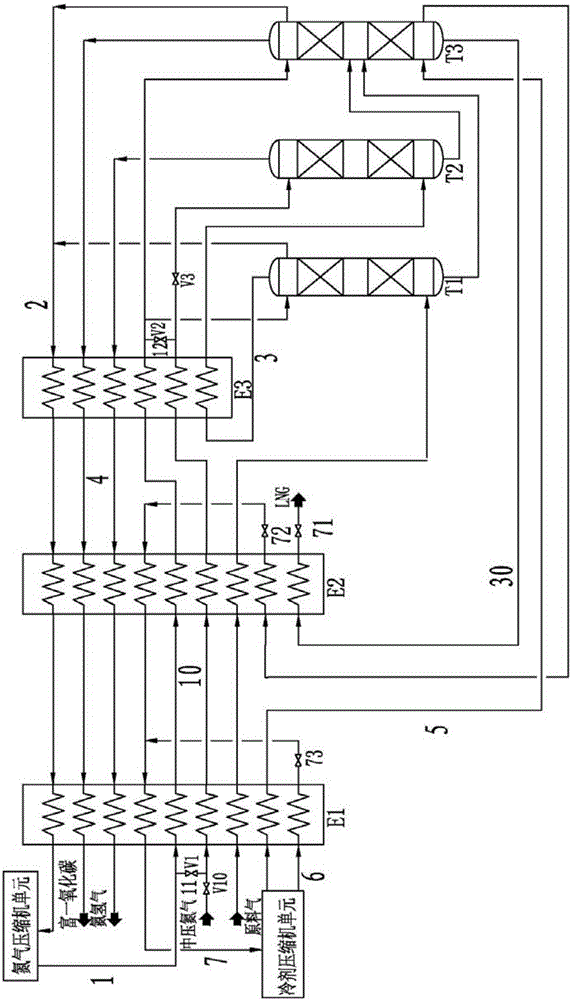

[0022] like figure 1 Shown, the system utilizing liquid nitrogen washing of the present invention to produce synthetic ammonia raw material gas and LNG comprises:

[0023] The first heat exchanger E1, which is used to initially cool down the raw material gas, is connected to the raw material gas source through pipelines;

[0024] The second heat exchanger E2, which is used to lower the temperature of the raw material gas initially cooled, is connected with the first heat exchanger E1 through a pipeline;

[0025] The dehydrogenation tower T1 used to dehydrogenate the raw material gas after cooling down again and separate the gas and liquid is connected to the second heat exchanger E2 through a pipeline;

[0026] Nitrogen washing tower T2, which is used to nitrogen wash the gas phase separated from the raw material gas and discharge nitrogen and hydrogen, is connected to the gas phase outlet of the dehydrogenation tower T1 through a pipeline;

[0027] The liquid phase separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com