Method for treating residual silt in slope shoulder position through blasting silt extrusion

A technology of blasting silt and silt, which is applied in blasting, soil protection, construction, etc. It can solve the problems of incomplete quality requirements, poor treatment effect, and reduced silt thickness, so as to shorten the construction period, improve construction efficiency, and improve construction efficiency. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

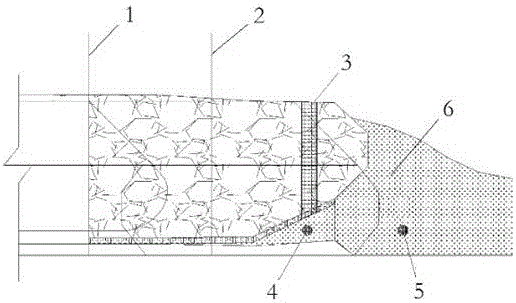

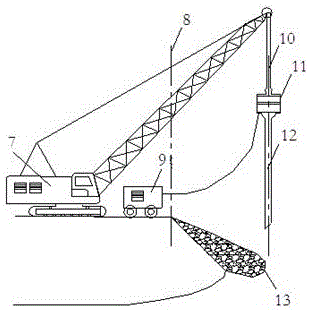

[0030] A method of blasting silting to deal with the residual silt at the slope shoulder. The hole is drilled by impact drilling on land, and the explosives are directly placed in the residual silt of the slope shoulder, and the explosives are deployed on the sea side at the same time. Blast, and deal with the residual silt at the slope shoulder.

[0031] The blasting and silting construction involved in this example is as follows: the total length of the permanent revetment is 6390m, the backfilling of the 45m wide embankment core stone inside the revetment has been completed in the early stage, and the outer 15m is treated with controlled loading blasting and silting replacement method for soft foundation treatment, and blasting silting treatment The soil layer is the first large layer of soil on the surface, and the thickness of the soil layer is 15m.

[0032] Construction quality requirements: The first large layer of soil on the surface is treated by blasting and silting,...

Embodiment 2

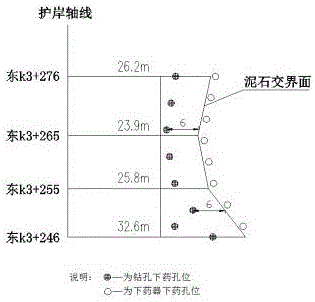

[0064] The operation of each step of a method for treating residual silt at the shoulder position by blasting described in this embodiment is the same as that in Embodiment 1, and the different technical parameters are:

[0065] 1) Determine the location of the percussion drilled hole as 5m away from the mud-rock interface;

[0066] 2) The distance between the charge holes of each row of explosives is 3.5m;

[0067] 3) When installing, reserve a distance of 5m between the hole wall and the outside of the bellows;

[0068] 4) Six sections of non-electric millisecond detonators are connected between the drilling charge and the detonating cord of the charge device;

[0069] 5) Perform 135ms differential blasting.

Embodiment 3

[0071] The operation of each step of a method for treating residual silt at the shoulder position by blasting described in this embodiment is the same as that in Embodiment 2, and the different technical parameters are:

[0072] 1) Determine the location of the percussion drilling hole to be 7m away from the mud-rock interface;

[0073] 2) The distance between the charge holes of each row of explosives is 4.5m;

[0074] 3) When installing, reserve a distance of 10m between the hole wall and the outside of the bellows;

[0075] 4) 8 sections of non-electric millisecond detonators are connected between the drilling charge and the detonating cord of the charge device;

[0076] 5) Carry out 160ms differential blasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com