Method and system for filtering online monitored noise of steel rail cracks and judging cracks

A noise filtering and judging method technology, which is applied in processing detection response signals, using acoustic wave emission technology for material analysis, instruments, etc., can solve problems such as inability to decompose and express well, and achieve high separation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

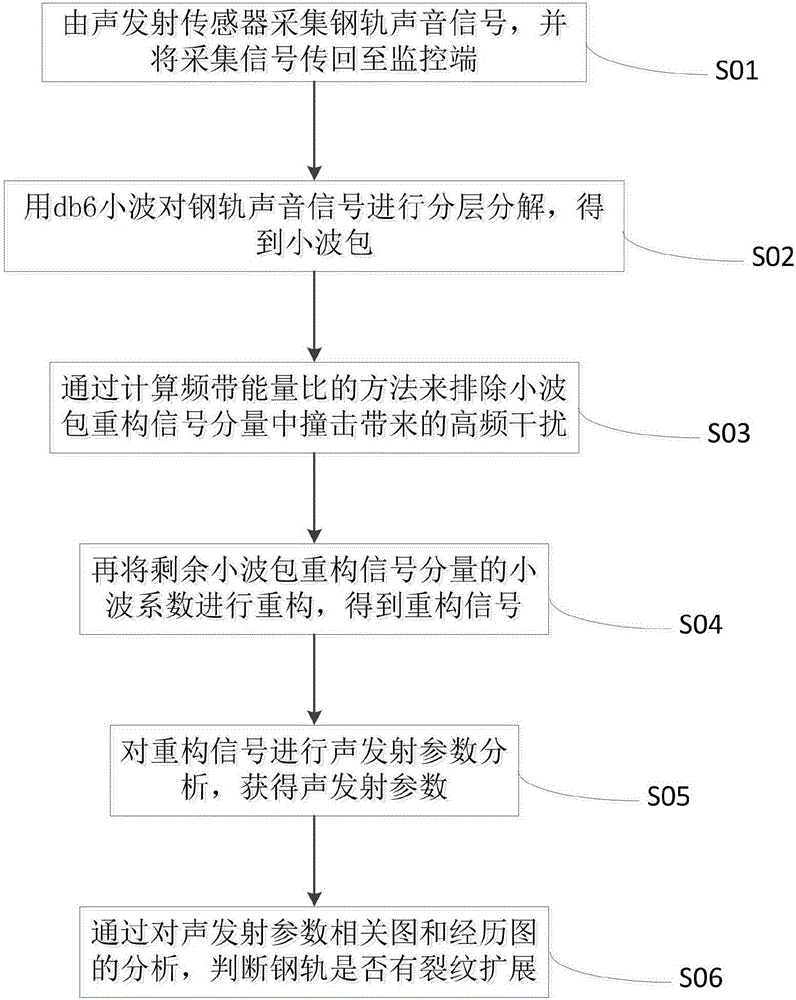

[0042] In the invention examples, see figure 1 As shown, the present invention proposes a rail crack online monitoring noise filtering and crack determination method, comprising steps:

[0043] S01: The acoustic emission sensor collects the rail sound signal, and sends the rail sound signal back to the monitoring end for processing.

[0044] Wherein, in step S01 , during the collection process, the duration of the rail sound signal is determined, and the rim abutment signal in the rail sound signal is excluded.

[0045] In step S01, if the rail sound signal is a signal in which convex peaks and valleys interact to form a concave-convex interlaced signal, and the peak peaks in the interlaced part emit a series of acoustic emission signals of elastic waves, then the rail s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com