An extreme ultraviolet single-stage diffraction grating

A single-order diffraction and extreme ultraviolet technology, applied in the field of micro-nano optics, can solve problems such as errors, reduced spectral accuracy, and inaccurate analysis results, and achieve the effects of reducing errors, improving signal-to-noise ratio, and improving spectral accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

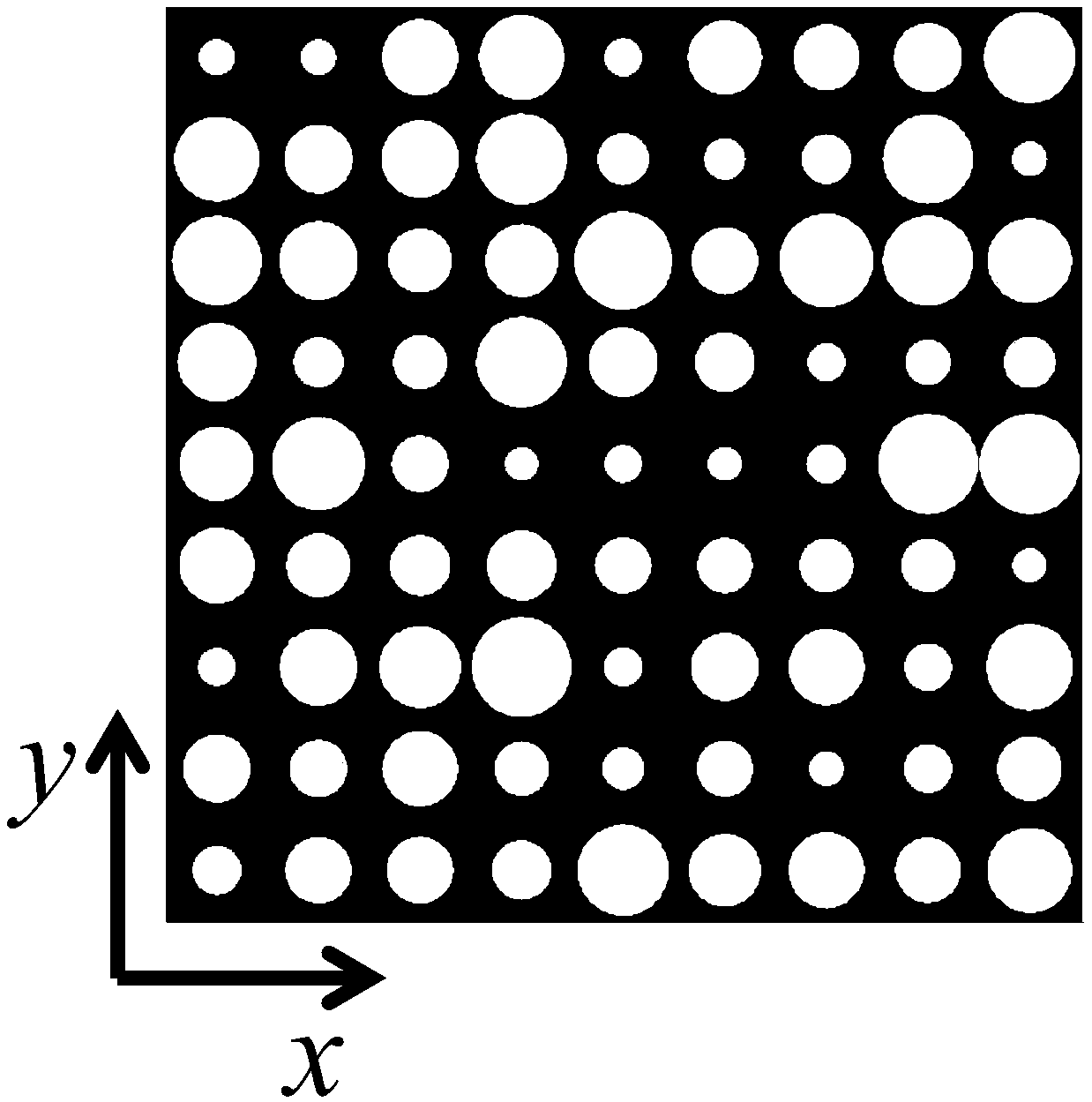

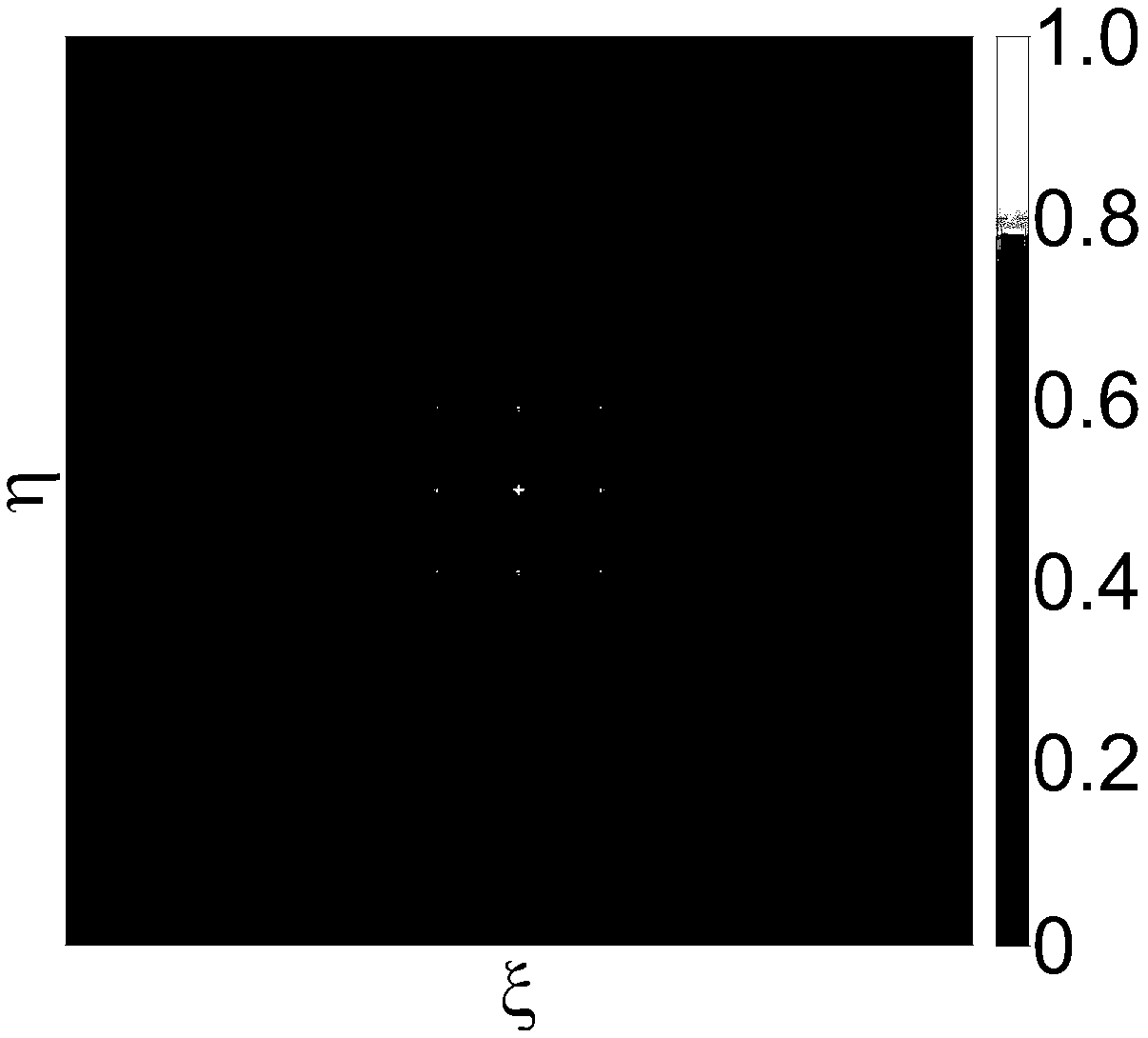

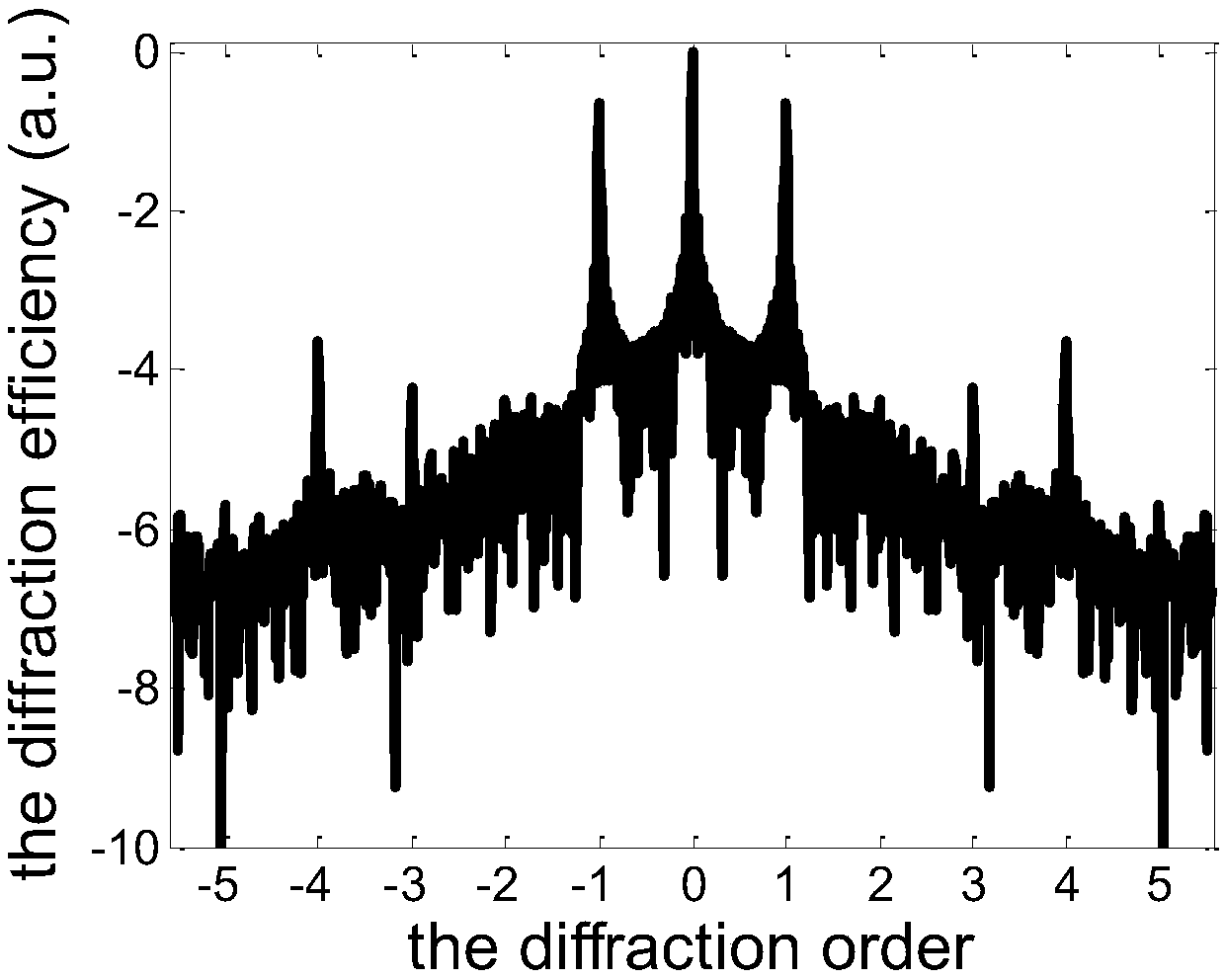

[0031] This embodiment provides an EUV single-stage diffraction grating, comprising: a light-transmitting substrate; an opaque film positioned on the light-transmitting substrate; holes; wherein, the circular light-transmitting through-holes are arranged on the opaque film in a periodic orthorhombic lattice distribution, the center of the circular light-transmitting through-holes is located at the center of the rhomboidal lattice, and the The radius of the circular light-transmitting hole is randomly distributed, and there is a maximum value R max and minimum R min ; In the plane where the opaque film is located, along the first direction, the period of the oblique grid is P x , along the second direction, the period of the orthorhombic lattice is P y , the first direction is perpendicular to the second direction; there is a preset ratio between the period of the rhombic lattice and the maximum and minimum radii of the circular light-transmitting holes.

[0032] See figure...

Embodiment 2

[0041] This embodiment provides an EUV single-stage diffraction grating, comprising: a light-transmitting substrate; an opaque film positioned on the light-transmitting substrate; holes; wherein, the circular light-transmitting through-holes are arranged on the opaque film in a periodic orthorhombic lattice distribution, the center of the circular light-transmitting through-holes is located at the center of the rhomboidal lattice, and the The radius of the circular light-transmitting hole is randomly distributed, and there is a maximum value R max and minimum R min ; In the plane where the opaque film is located, along the first direction, the period of the oblique grid is P x , along the second direction, the period of the orthorhombic lattice is P y , the first direction is perpendicular to the second direction; there is a preset ratio between the period of the rhombic lattice and the maximum and minimum radii of the circular light-transmitting holes.

[0042] See Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com