Coking gas desulfurization and denitrification integrated equipment centralized management and control system

A management and control system, centralized management and control technology, applied in general control system, control/regulation system, adaptive control, etc., can solve unfavorable modeling, optimization and control, few data sources in desulfurization and denitrification section, and no fusion analysis of coking production section And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

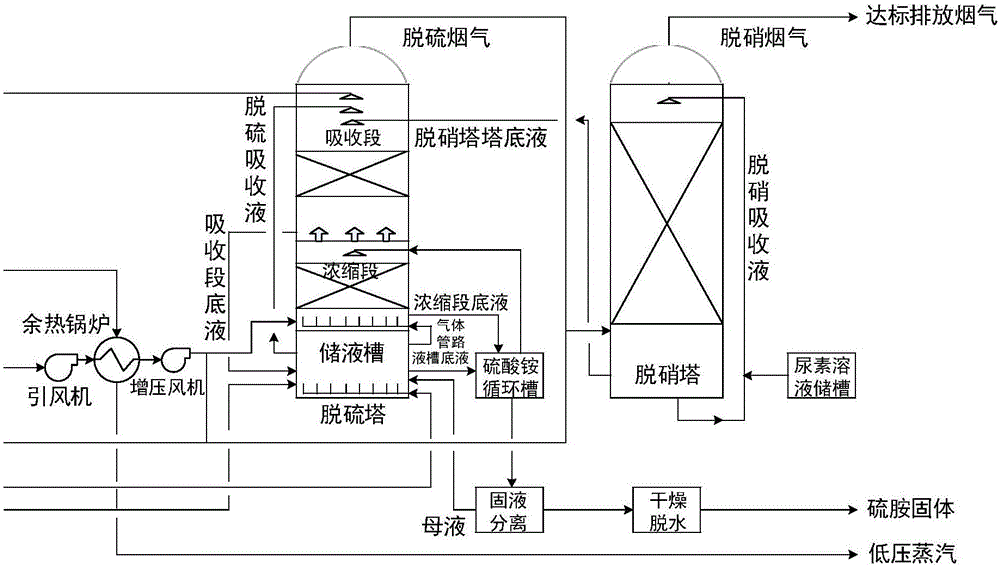

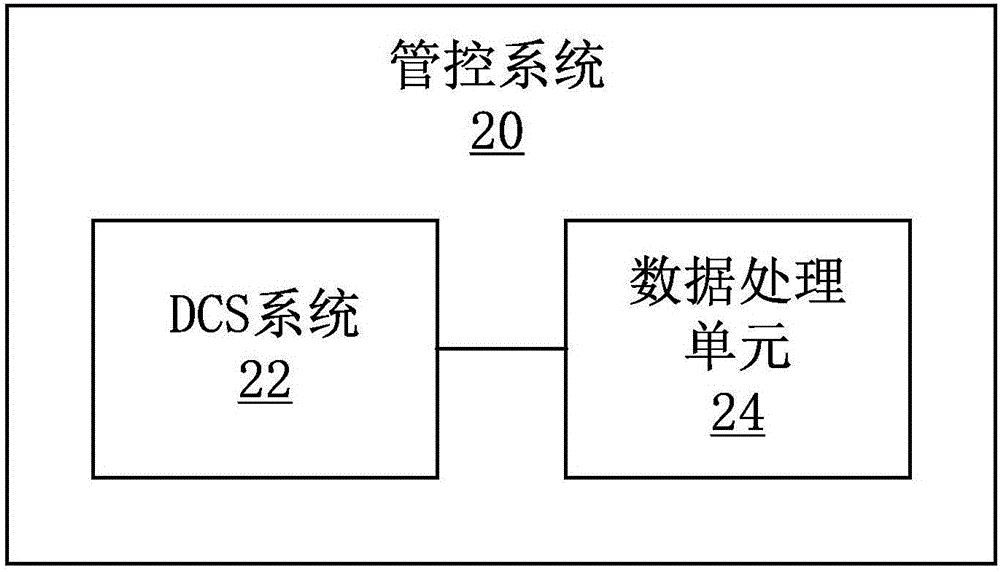

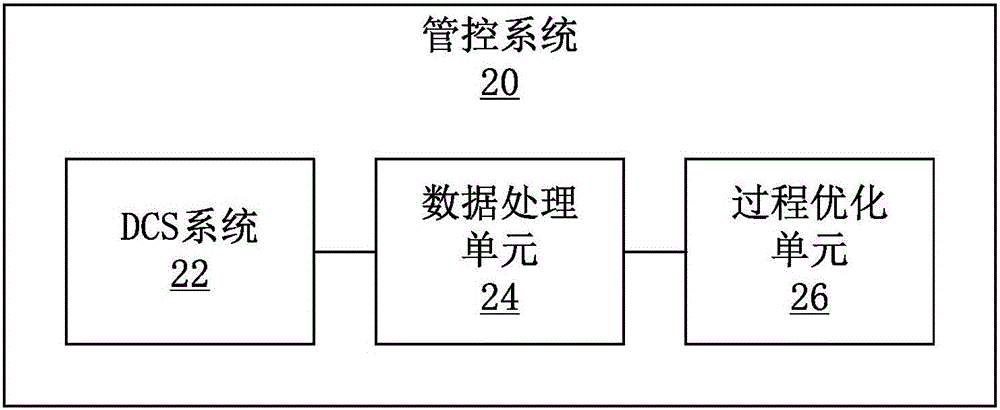

[0054] An embodiment of the present invention provides a centralized management and control system for coking flue gas desulfurization and destocking integrated equipment. Such as figure 2 As shown, the system 20 may include: a DCS system 22 and a data processing unit 24 in the coking production section and the integrated desulfurization and denitrification engineering section. Among them, the data processing unit 24 is used to collect the coking production process data and the production data, energy data and operating parameters of the flue gas desulfurization and denitrification integration process through the DCS system 22 of the coking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com