Structure and function integrated high-carbon damping vibration attenuation steel and preparation method thereof

A high-carbon, functional technology, applied in the field of structural-function integrated engineering materials, can solve problems such as high production costs, inability to meet high-damping materials, and no discovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

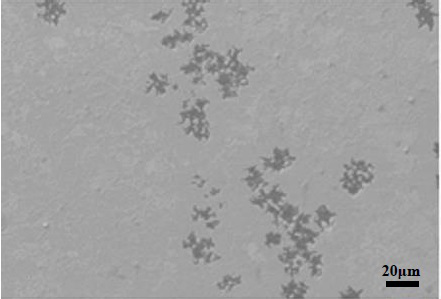

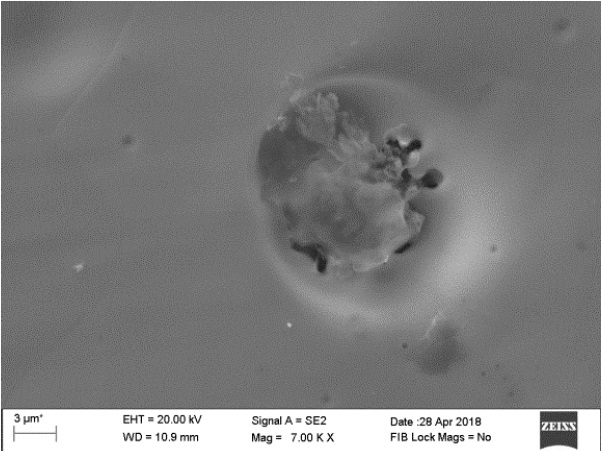

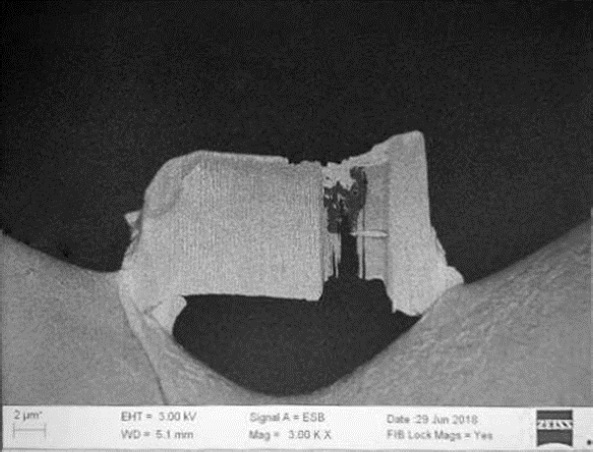

Image

Examples

Embodiment 1

[0033] Step 1: A high-carbon damping damping steel, the main elements in the steel are: C: 1.2%, Si: 1.6%, Mn: 0.210%, Ni: 2.2%, Al: 0.260%, balance: Fe . The batching was carried out according to the above-mentioned chemical composition, and a vacuum induction furnace was used for smelting, followed by gravity casting to prepare a 360kg steel ingot.

[0034] Step 2: Hot rolling the prepared ingot after homogenizing at high temperature, as follows: Process 1: Cut the ingot into a slab with a thickness of 60mm, heat it to 1150°C for 2 hours, and the initial rolling temperature is 1080°C, Carry out four passes of rough rolling first, with the lowering pressures being 15, 10, 7, and 5mm in turn, and the rolling temperatures in turn at 1080°C, 1010°C, 950°C, and 800°C, and finally rolled into a steel plate with a thickness of 26mm; process 2 : Carry out four passes of finish rolling, the down-pressing amount is 4, 3, 3, 2mm in turn, the rolling temperature is 780°C, 770°C, 760°C,...

Embodiment 2

[0040] Step 1: A high-carbon damping damping steel, the main elements in the steel are: C: 1.2%, Si: 1.6%, Mn: 0.210%, Ni: 2.2%, Al: 0.260%, balance: Fe . The batching was carried out according to the above-mentioned chemical composition, and a vacuum induction furnace was used for smelting, followed by gravity casting to prepare a 360kg steel ingot.

[0041] Step 2: Hot rolling the prepared ingot after homogenizing at high temperature, as follows: Process 1: Cut the ingot into a slab with a thickness of 60mm, heat it to 1150°C for 2 hours, and the initial rolling temperature is 1080°C, Carry out four passes of rough rolling first, with the lowering pressures being 15, 10, 7, and 5mm in turn, and the rolling temperatures in turn at 1080°C, 1010°C, 950°C, and 800°C, and finally rolled into a steel plate with a thickness of 26mm; process 2 : Carry out four passes of finish rolling, the down-pressing amount is 4, 3, 3, 2mm in turn, the rolling temperature is 780°C, 770°C, 760°C,...

Embodiment 3

[0045] Step 1: A high-carbon damping damping steel, the main elements in the steel are: C: 1.2%, Si: 1.6%, Mn: 0.210%, Ni: 2.2%, Al: 0.260%, balance: Fe . The batching was carried out according to the above-mentioned chemical composition, and a vacuum induction furnace was used for smelting, followed by gravity casting to prepare a 360kg steel ingot.

[0046] Step 2: Hot rolling the prepared ingot after homogenizing at high temperature, as follows: Process 1: Cut the ingot into a slab with a thickness of 60mm, heat it to 1150°C for 2 hours, and the initial rolling temperature is 1080°C, Carry out four passes of rough rolling first, with the lowering pressures being 15, 10, 7, and 5mm in turn, and the rolling temperatures in turn at 1080°C, 1010°C, 950°C, and 800°C, and finally rolled into a steel plate with a thickness of 26mm; process 2 : Carry out four passes of finish rolling, the down-pressing amount is 4, 3, 3, 2mm in turn, the rolling temperature is 780°C, 770°C, 760°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com