Brushless double-fed motor super-synchronization speed control system and motor field orientation vector control method and motor direct torque control method for brushless double-fed motor super-synchronization speed control system

A technology of doubly-fed motor and speed control system, which is applied in the direction of connection with control/drive circuit, electronic commutator, magnetic circuit rotating parts, etc. The problem of high cost is to reduce the additional loss, improve the electromechanical energy conversion efficiency, and achieve the effect of high motor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

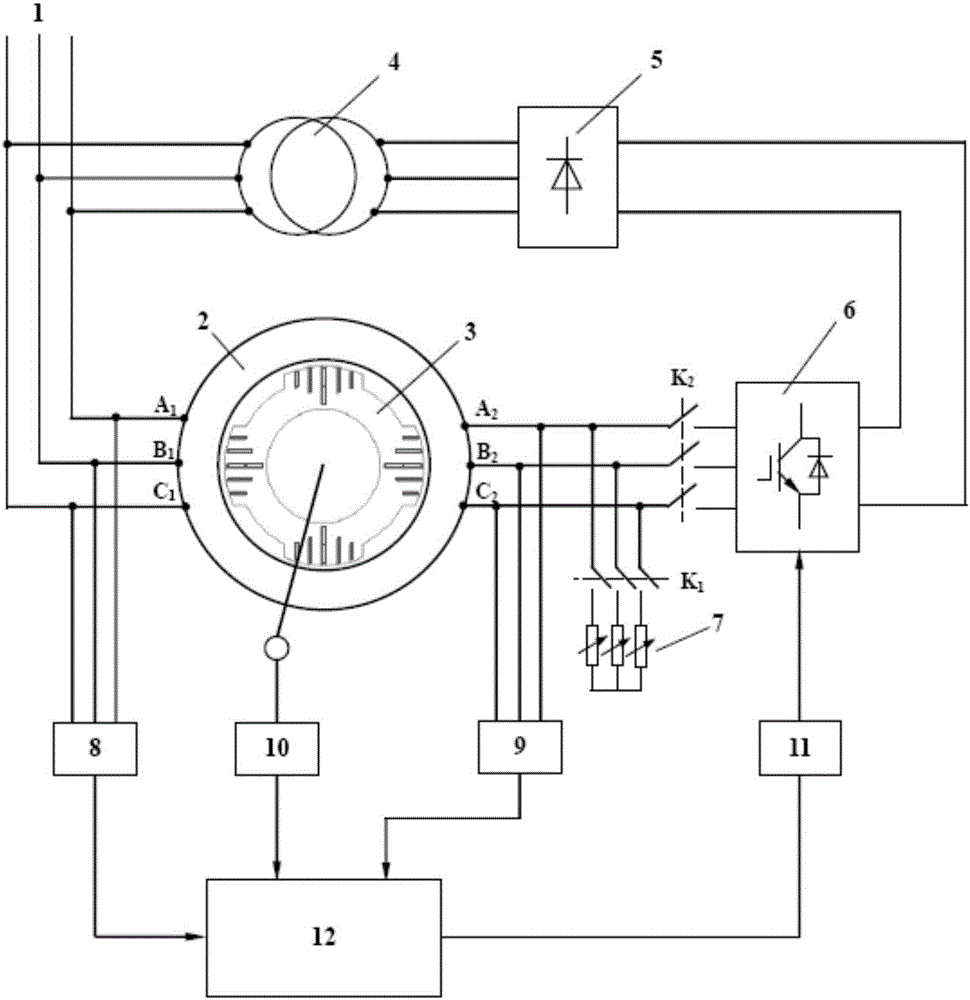

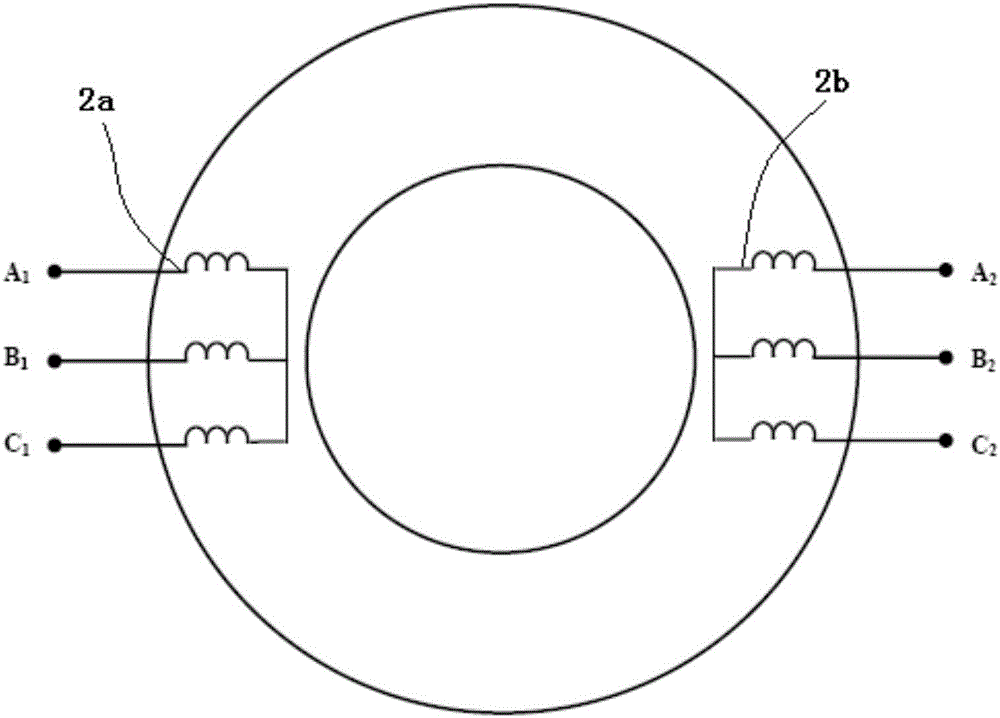

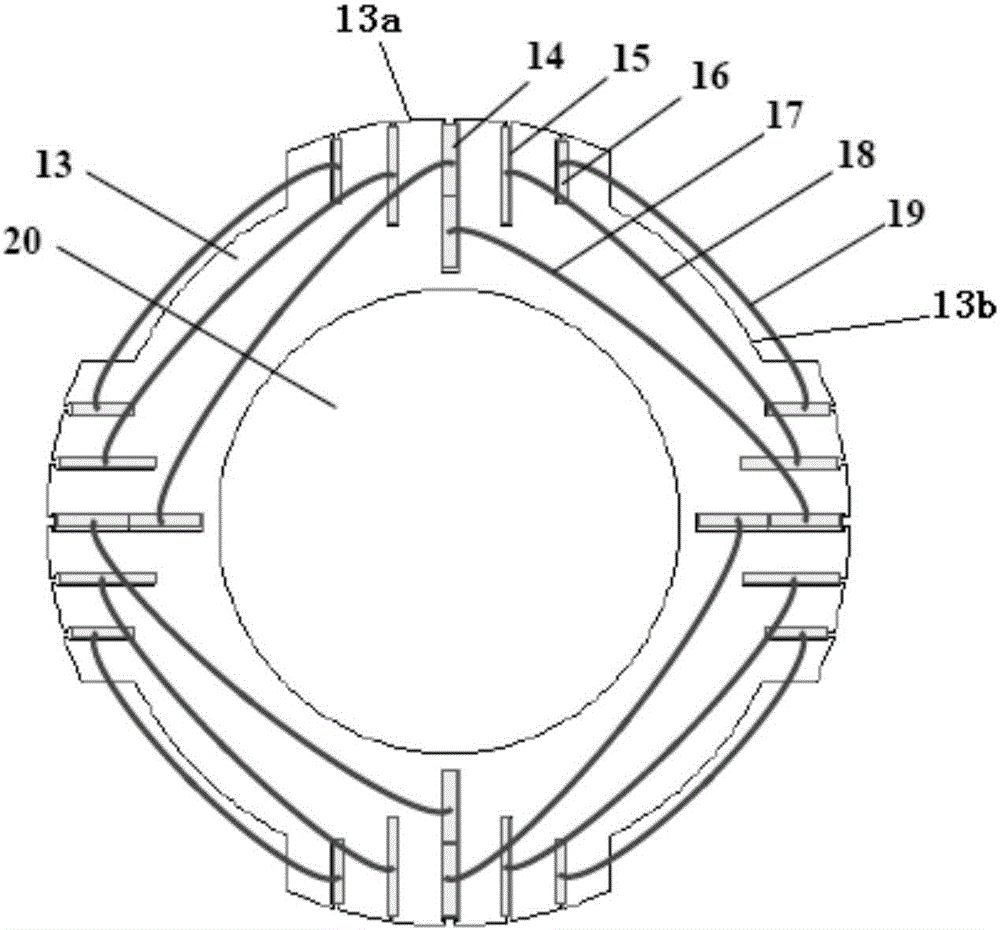

[0045] see Figure 1 to Figure 3 As shown, the present invention discloses a super-synchronous speed regulation system of a brushless double-fed motor. The speed regulation system includes a power supply 1, a brushless double-fed motor stator 2, a brushless double-fed motor rotor 3, a transformer 4, a rectifier 5, and a frequency converter 6. Starting resistor 7, drive unit 11, controller 12, switch K 1 and switch K 2 ; Two sets of independent three-phase symmetrical windings are placed in the iron core slot of the stator, respectively the main winding 2a and the auxiliary winding 2b, and the outgoing terminal A of the main winding 2a 1 , B 1 、C 1 Connected to the power supply 1, the outlet terminal A of the secondary winding 2b 2 , B 2 、C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com