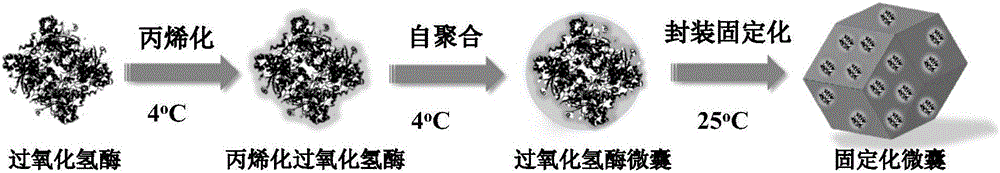

Preparation method of compound biomimetic mineralization nano biocatalyst

A biocatalyst, biomimetic mineralization technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the difficult recovery of nano-microcapsules and the rapid loss of enzyme activity and other problems, to achieve the effects of increasing solvent stability and use stability, less enzyme damage, and reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

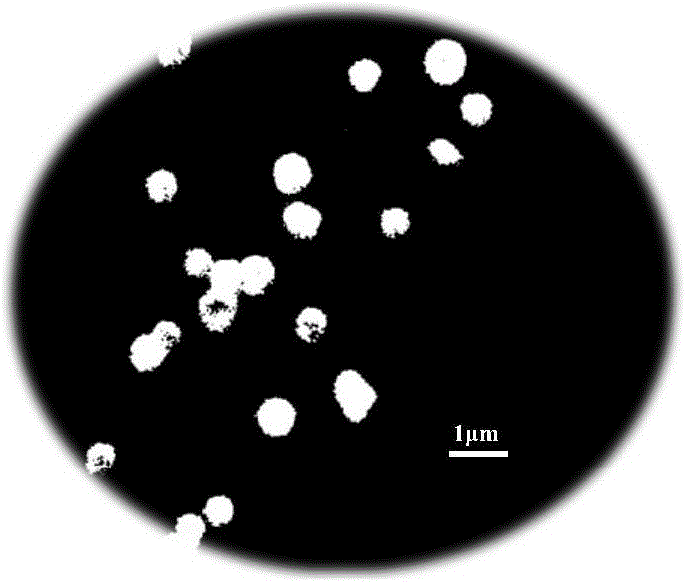

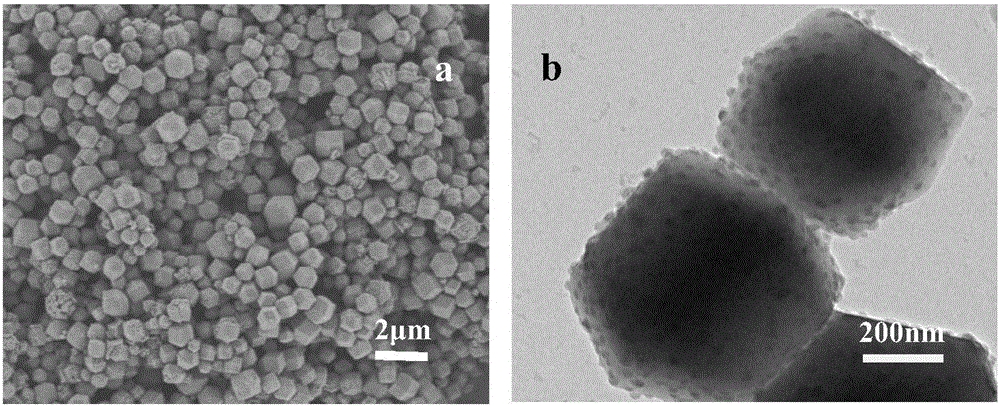

[0039] According to the molar ratio of 30mg catalase: N-acryloyloxysuccinamide (NASM)=1:5, mix 30mg (0.5μmol) catalase with N-acryloyloxysuccinamide (NASM) (2.5μmol) was dissolved in 20mL of PBS to start the acylation reaction. The reaction vessel was a 100mL three-neck flask, kept in a constant temperature water bath at 4°C, and simultaneously reacted with 520r / min magnetic stirring for 2h. Add the pre-modified PGA to the monomer acrylamide (AAM) and N-(3-aminopropyl)-methacryl ester (APM) sequentially at a molar ratio of 1:2500:500:200, crosslinking agent N, N '-methylene acrylamide (BIS). After stirring evenly, 60 mg of ammonium persulfate (APS) and 50 μL of tetramethylethylenediamine (TEMED) were added as triggers, and the reaction was carried out in a constant temperature water bath at 4°C while magnetically stirring at 520 r / min for 4 h. Transfer 20mL of the obtained brown-yellow solution to a 50mL dialysis bag, place it in a beaker of 1000mL pure water to start dialysi...

Embodiment 2

[0046] Dissolve 30 mg of catalase (0.5 μmol) and N-acryloyloxysuccinamide (NASM) (2.5 μmol) in 20 mL of PBS at a molar ratio of 1:5 to start the acylation reaction. The flask was placed in a constant temperature water bath at 4°C while magnetically stirring at 520r / min for 2h. Add the pre-modified PGA to the monomer acrylamide (AAM) and N-(3-aminopropyl)-methacryl ester (APM) sequentially at a molar ratio of 1:2500:500:200, crosslinking agent N, N '-methylene acrylamide (BIS). After stirring evenly, 60 mg of ammonium persulfate (APS) and 50 μL of tetramethylethylenediamine (TEMED) were added as triggers, and the reaction was carried out in a constant temperature water bath at 4°C while magnetically stirring at 520 r / min for 4 hours. Transfer the resulting 20mL brown-yellow solution to a 50mL dialysis bag, place it in a beaker of 1000mL pure water to start dialysis, the dialysis should be carried out in a water bath at 15°C, give 200r / min stirring to accelerate the dialysis, d...

Embodiment 3

[0050]Dissolve 30 mg of catalase (0.5 μmol) and N-acryloyloxysuccinamide (NASM) (2.5 μmol) in 20 mL of PBS at a molar ratio of 1:5 to start the acylation reaction. The flask was placed in a constant temperature water bath at 4°C while magnetically stirring at 520r / min for 2h. Add the pre-modified PGA to the monomer acrylamide (AAM) and N-(3-aminopropyl)-methacryl ester (APM) sequentially at a molar ratio of 1:2500:500:200, crosslinking agent N, N '-methylene acrylamide (BIS). After stirring evenly, 60 mg of ammonium persulfate (APS) and 50 μL of tetramethylethylenediamine (TEMED) were added as triggers, and the reaction was carried out in a constant temperature water bath at 4°C while magnetically stirring at 520 r / min for 4 hours. Transfer the resulting 20mL brown-yellow solution to a 50mL dialysis bag, place it in a beaker of 1000mL pure water to start dialysis, the dialysis should be carried out in a water bath at 20°C, give 200r / min stirring to accelerate the dialysis, du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com