Preparation method of spray drying equipment

A technology of drying equipment and nozzle, which is applied in the field of preparation of spray drying equipment, can solve the problems of low capacity utilization efficiency, poor process control conditions, and small application range, and achieve safe and reliable working principle, fewer atomization process steps, The effect of easy control of atomization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

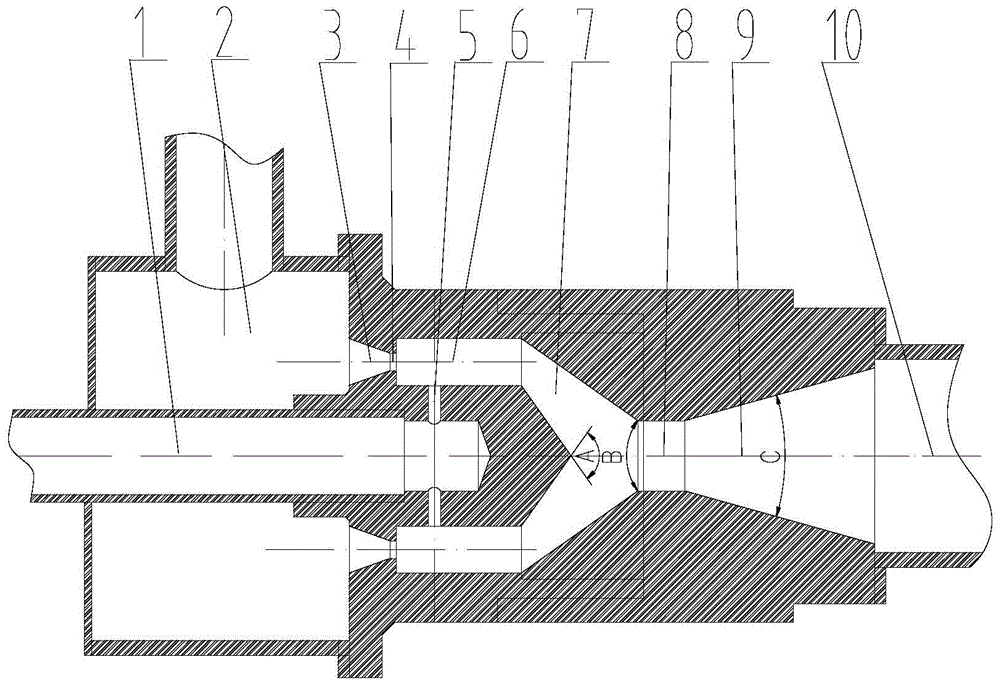

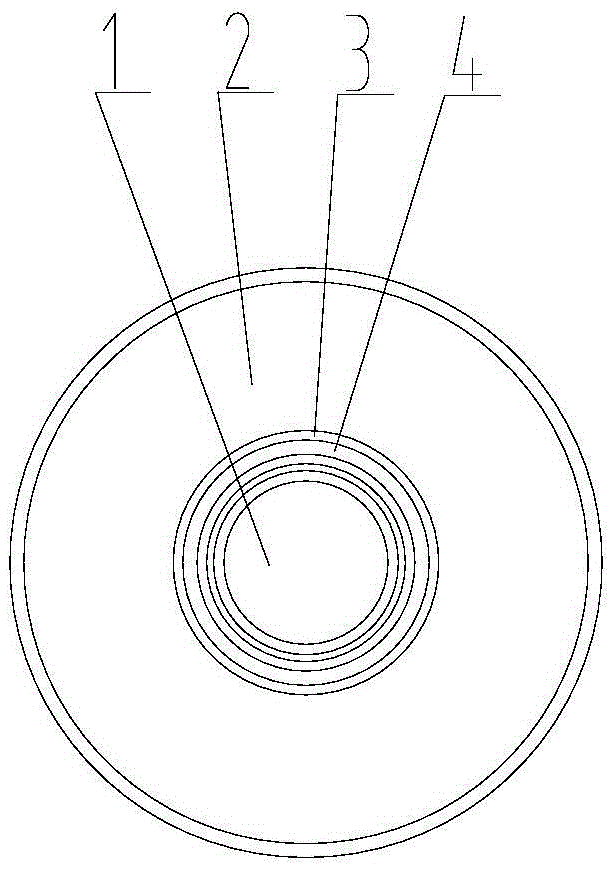

[0016] In this embodiment, an appropriate steam is used to carry out spray atomization drying to the resin solution, and the resin solution is a resin solution containing polycarbonate with a mass fraction of 10%-30% in dichloromethane; the steam feed is a mass fraction of 229.5kg / h , the steam inlet pressure is 1.45MPa, the mass fraction of the resin solution is 500kg / h, the mass fraction of polycarbonate in the resin solution is 20.3%, the diameter of the feed pipe 1 is 25mm, the diameter of the steam chamber 2 is 108mm, and the nozzle shrinkage part 3 The diameters of the two ends are 12mm and 4mm respectively, the nozzle throat 4 is 4mm, the diameter of the round hole 5 on the side wall of the feed pipe is 2mm, the number of the holes is 2, the diameter of the atomization chamber 6 is 12mm, and the angle A of the impact cone 7 is 109 °, the angle B is 60 °, the diameter of the discrete vertebral body straight pipe section 8 is 20 mm, the discrete vertebral body expansion se...

Embodiment 2

[0018] The steam feed of present embodiment is quality 230kg / h, and steam inlet pressure is 1.47MPa, and the quality of resin solution is 700kg / h, and the mass fraction of polycarbonate is 19.19% in the resin solution, and feed pipe 1 diameter is 25mm, and steam The diameter of the chamber 2 is 108 mm, the diameters of the two ends of the nozzle contraction part 3 are 12 mm and 4 mm respectively, the nozzle throat 4 is 4 mm, the diameter of the feed pipe side wall circular hole 5 is 2.5 mm, the number is 2, and the atomization chamber 6 The diameter is 12mm, the angle A of the impacting vertebral body 7 is 109°, the angle B is 60°, the diameter of the straight pipe section 8 of the discrete vertebral body is 20mm, the angle C of the expanding section 9 of the discrete vertebral body is 15°, and the diameter of the outlet 10 is 50mm; The distribution of particles at the outlet is obtained (percentage is mass percentage): the percentage of >4mm particles is 5.77, the percentage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com