Selenium-enriched plant nutrient for injection

A technology of selenium-enriched plants and nutrients, applied in the direction of application, fertilizer mixture, organic fertilizer, etc., can solve the problems of excessive heavy metal content in fruits, achieve the effects of reducing fruit morbidity and shedding rate, promoting fruit growth, and facilitating transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

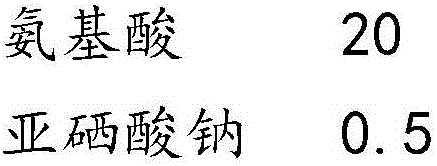

Embodiment 1

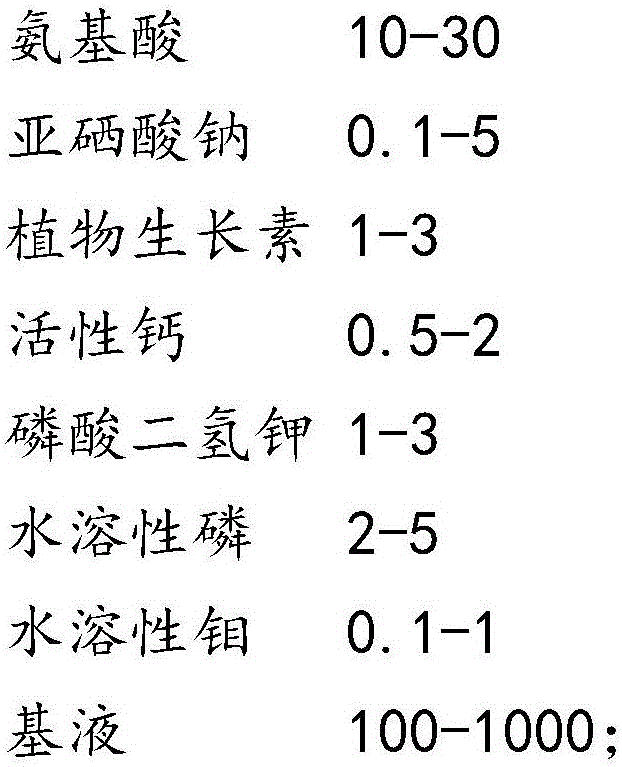

[0035] In the embodiment of the present invention, the production process of raw materials according to weight is as follows:

[0036] (1) Put 500kg of water into the reaction kettle, open the steam valve, heat up the reaction kettle, control the reaction temperature at 60-75°C, keep it for 15 minutes, then open the reaction kettle for stirring, and control the stirring speed at 260-280 rpm Minutes, then add 0.6kg of active calcium, 2kg of potassium dihydrogen phosphate and 0.5kg of sodium selenite from the high tank, and mix for 35 minutes to fully dissolve and mix the materials;

[0037] (2) After the stirring is completed, the materials in the reactor are lowered to normal temperature, and 20kg of amino acid, 1kg of plant auxin, 3kg of water-soluble phosphorus and 0.5kg of water-soluble molybdenum are put in, first stirred for 10-15 minutes, and then the temperature of the kettle is raised to control the temperature Stir continuously for 20 minutes at 70°C at 260-280 rpm; ...

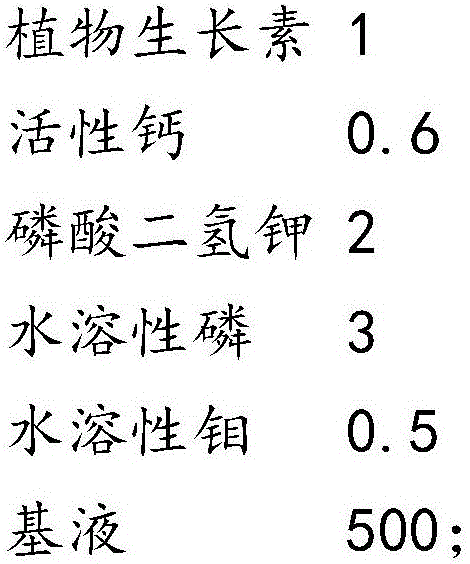

Embodiment 2

[0041] In the embodiment of the present invention, the production process of raw materials according to weight is as follows:

[0042] (1) Put 300kg of water and 300kg of organic enzyme solution into the reaction kettle, open the steam valve, heat up the reaction kettle, control the reaction temperature at 60-75°C, keep it for 15 minutes, then open the reaction kettle for stirring, and the stirring speed is controlled at 260-280 rpm, then add 0.5kg of active calcium, 2.5kg of potassium dihydrogen phosphate and 0.6kg of sodium selenite from the high tank, and mix for 35 minutes to fully dissolve and mix the materials;

[0043] (2) After the stirring is finished, the materials in the reactor are lowered to normal temperature, and 15kg of amino acids, 0.6kg of plant auxin, 2.5kg of water-soluble phosphorus and 0.8kg of water-soluble molybdenum are dropped into, first stirred for 10-15 minutes, and then the temperature of the kettle is raised. Control the temperature at 70°C, and ...

Embodiment 3

[0047] In the embodiment of the present invention, the production process of raw materials according to weight is as follows:

[0048] (1) Put 800kg of organic enzyme liquid into the reaction kettle, open the steam valve, heat up the reaction kettle, control the reaction temperature at 60-75°C, keep it for 15 minutes, then open the reaction kettle for stirring, and control the stirring speed at 260-280 R / min, then add 1.5kg of active calcium, 3kg of potassium dihydrogen phosphate and 0.7kg of sodium selenite from the high tank, and mix for 35 minutes to fully dissolve and mix the materials;

[0049] (2) After the stirring is finished, the materials in the reactor are lowered to normal temperature, and 25kg of amino acid, 2.5kg of auxin, 3kg of water-soluble phosphorus and 0.7kg of water-soluble molybdenum are put into the reactor, first stirred for 10-15 minutes, and then the temperature of the kettle is raised to control Stir continuously for 20 minutes at 260-280 rpm at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com