Antifogging detergent and preparation method thereof

The technology of a cleaning agent and an anti-fogging agent is applied in the field of anti-fogging cleaning agent and its preparation, which can solve the problem that the anti-fogging effect needs to be improved, and achieve the effect of strong decontamination ability and reasonable and scientific compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

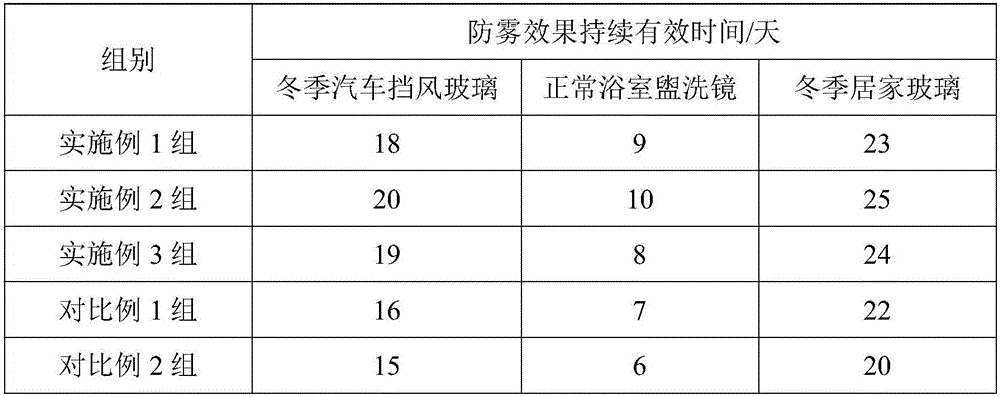

Examples

Embodiment 1

[0016] Embodiment 1 A kind of anti-fog cleaning agent

[0017] Described anti-fog cleaning agent is made up of following component and weight percentage thereof:

[0018] Polyoxyethylene Cocoate 4%, Alkylphenol Ethoxylates 2%, Sodium Lauryl Sulfate 4%, Methyl Acrylate 2%, Sorbitan Palmitate 2%, Coco Alkanolamide 1 %, protocatechuic acid 1%, propylene glycol ether 25%, glycerin 5%, ethanol 5%, borax 1% and water 48%.

[0019] Preparation method: first add ethanol and water, while stirring, add propylene glycol ether, polyoxyethylene cocoate, alkylphenol polyoxyethylene ether, sodium lauryl sulfate methyl acrylate, sorbitan palmitate and coconut Oil alkanolamide, finally add protocatechuic acid, glycerin and borax, stir until transparent, that is.

Embodiment 2

[0020] Embodiment 2 A kind of anti-fog cleaning agent

[0021] Described anti-fog cleaning agent is made up of following component and weight percentage thereof:

[0022] Polyoxyethylene Cocoate 6%, Alkylphenol Ethoxylates 3%, Sodium Lauryl Sulfate 6%, Methyl Acrylate 3%, Sorbitan Palmitate 3%, Coco Alkanolamide Spray 1.5%, protocatechuic acid 3%, propylene glycol ether 30%, glycerin 7.5%, ethanol 7.5%, borax 3% and water 26.5%.

[0023] The preparation method is similar to Example 1.

Embodiment 3

[0024] Embodiment 3 A kind of anti-fog cleaning agent

[0025] Described anti-fog cleaning agent is made up of following component and weight percentage thereof:

[0026] Polyoxyethylene Cocoate 8%, Alkylphenol Ethoxylates 4%, Sodium Lauryl Sulfate 8%, Methyl Acrylate 4%, Sorbitan Palmitate 4%, Coco Alkanolamide Spray 2%, protocatechuic acid 5%, propylene glycol ether 35%, glycerin 10%, ethanol 10%, borax 5% and water 5%.

[0027] The preparation method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com