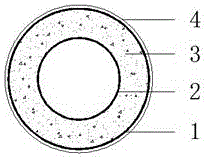

Method for compositely strengthening steel pipe column through external sleeveing of circular steel pipe concrete fibre composite materials

A technology of steel pipe concrete and reinforced steel pipes, which is applied in building maintenance, construction, building construction, etc., can solve the problems of increasing the cross-sectional area of the structure's self-weight, high installation and transportation costs, and reduced material utilization, so as to shorten the construction period and save engineering Cost, the effect of reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The self-stressing self-compacting concrete is composed of the following components in proportion by weight: cement: water: sand: stone = 1:0.33:0.85:0.97, and also includes 0.8% water reducing agent by weight.

Embodiment 2

[0043] The self-stressing self-compacting concrete is composed of the following components in proportion by weight: cement: water: sand: stone = 1:0.28:0.90:1.01, and also includes 1.2% water reducing agent by weight.

Embodiment 3

[0045] The self-stressing self-compacting concrete is composed of the following components in proportion by weight: cement: water: sand: stone = 1:0.23:1.08:1.09, and also includes 2.5% water reducing agent by weight.

[0046] Experimental measurements show that the fluidity of the self-stressing self-compacting concrete prepared in this patent is good, and the degree of expansion is in the range of 645-655mm. With the reduction of the water-cement ratio in the formulas of the above three groups of embodiments, the viscosity of the concrete slurry increases. Large, for the standard 150×150×150mm cube sample block, the cubic compressive strength increases, which are 45MPa, 54MPa, and 61MPa in turn.

[0047] The fiber-reinforced composite material is at least one of carbon fiber, aramid fiber, ultra-high molecular weight polyethylene fiber, glass fiber, basalt fiber, and aramid fiber. It is a light-weight and high-strength material that can make up for the poor corrosion resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com