An adapter for bellows

A technology for adapters and pipes, applied in the direction of hose connection devices, pipes/pipe joints/pipes, equipment for connecting/terminating cables, etc., which can solve the problem of protection level, poor environmental tolerance, expensive production and material costs, and impact on sealing. and other problems, to achieve the effect of good environmental tolerance and pullout resistance, easy assembly or disassembly, and reliable sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

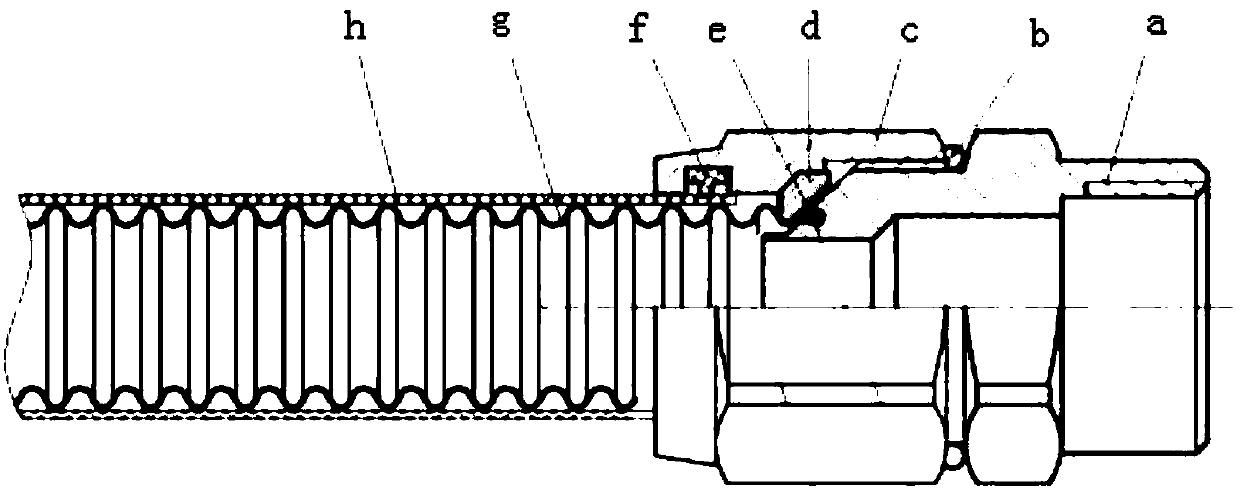

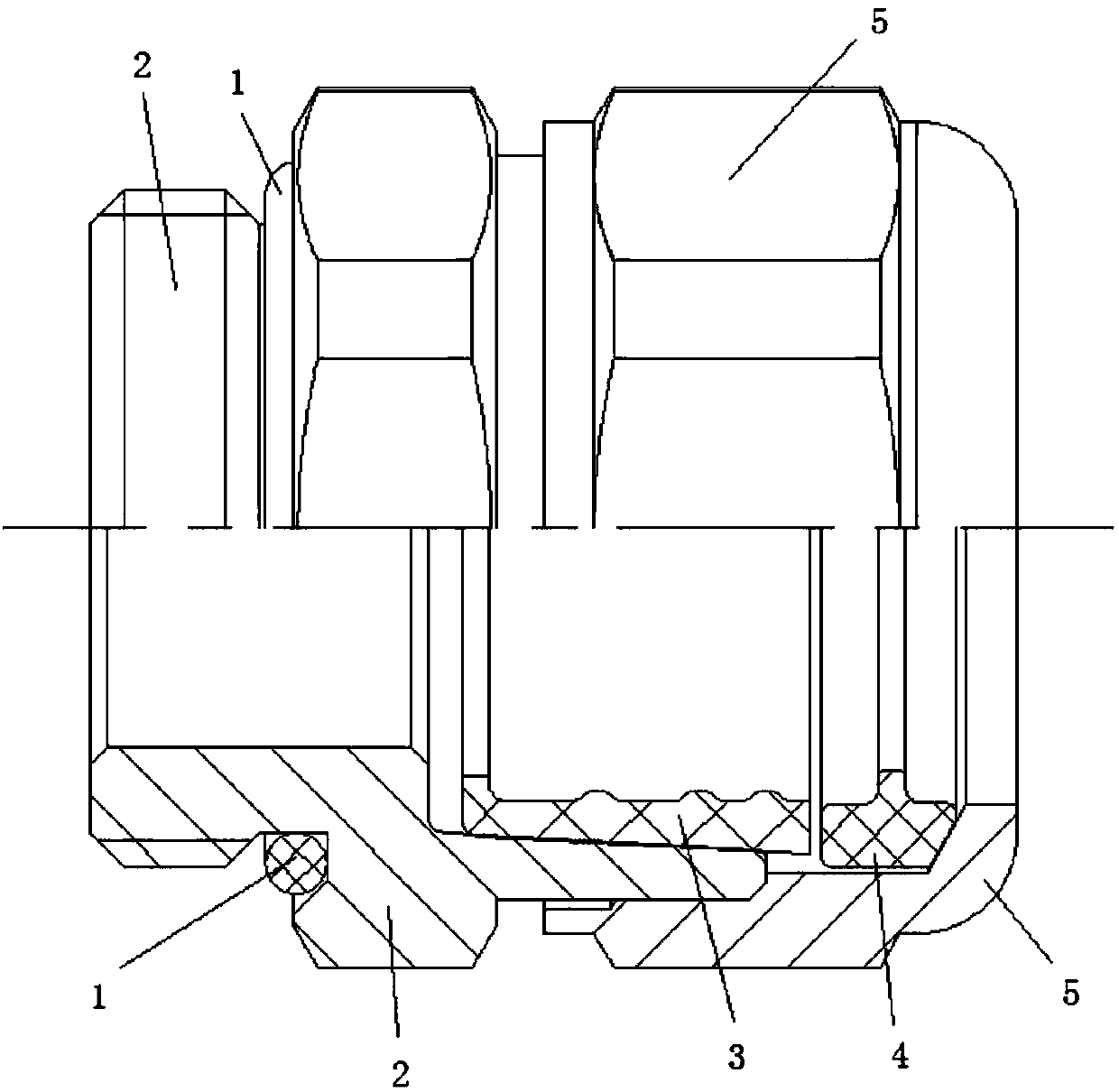

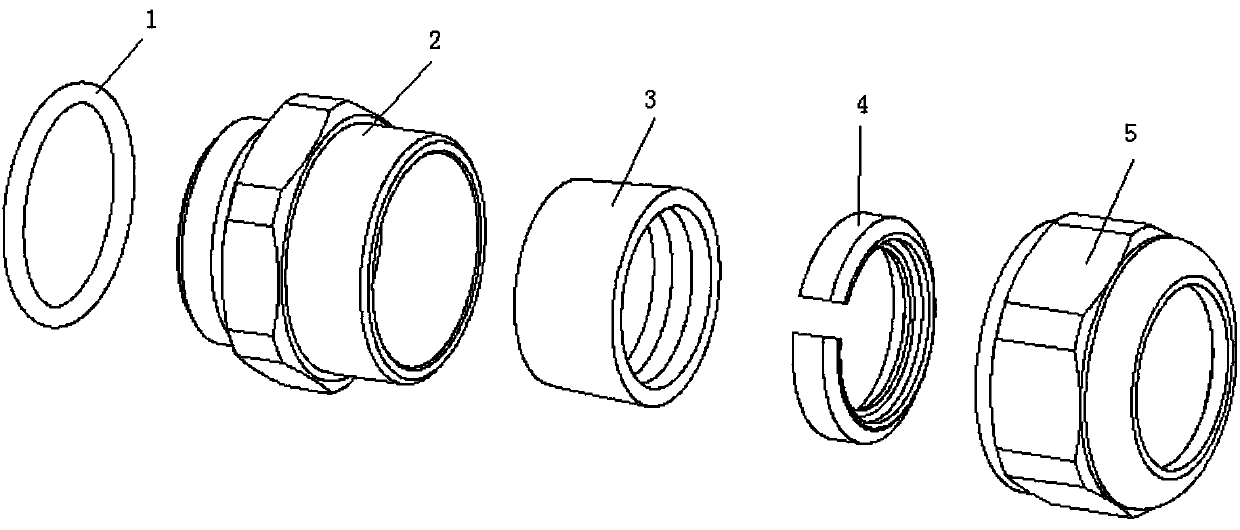

[0038] see Figure 2-7 , an adapter for bellows, its specific structure is: comprising a body, the body includes an O-ring 1, a connecting screw 2, a sealing rubber 3, a clamping ring 4 and a clamping nut 5 arranged concentrically with the central axis, see figure 2 with image 3 . The length of the body is 1.25 times the diameter of the corrugated pipe, where the length of the body is 20mm (the length here is the effective length without the thread).

[0039] The structure of the connecting screw 2 is detailed in Figure 2-Figure 4 , specifically a hollow structure, the outer wall of its first end is provided with a groove 2.1 for setting the O-ring 1, and the outer wall of its second end is provided with a groove 2.1 on the inner wall of the first end of the hoop nut 5. The external thread matched with the internal thread, the hoop nut 5 and the connecting screw 2 are connected by threads, which is convenient for installation and disassembly, and has good sealing perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com