Piezoelectric dispenser with a longitudinal transducer and replaceable capillary tube

A capillary and distributor technology, applied in chemical instruments and methods, injection devices, fluid controllers, etc., to achieve large distribution flexibility, eliminate the need for cleaning, and avoid degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

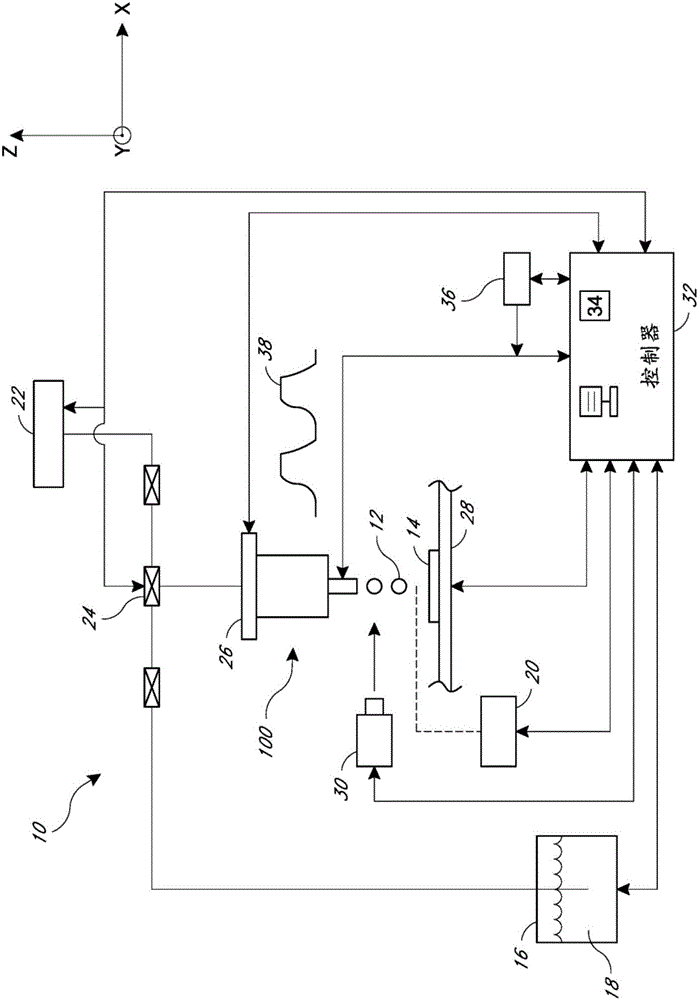

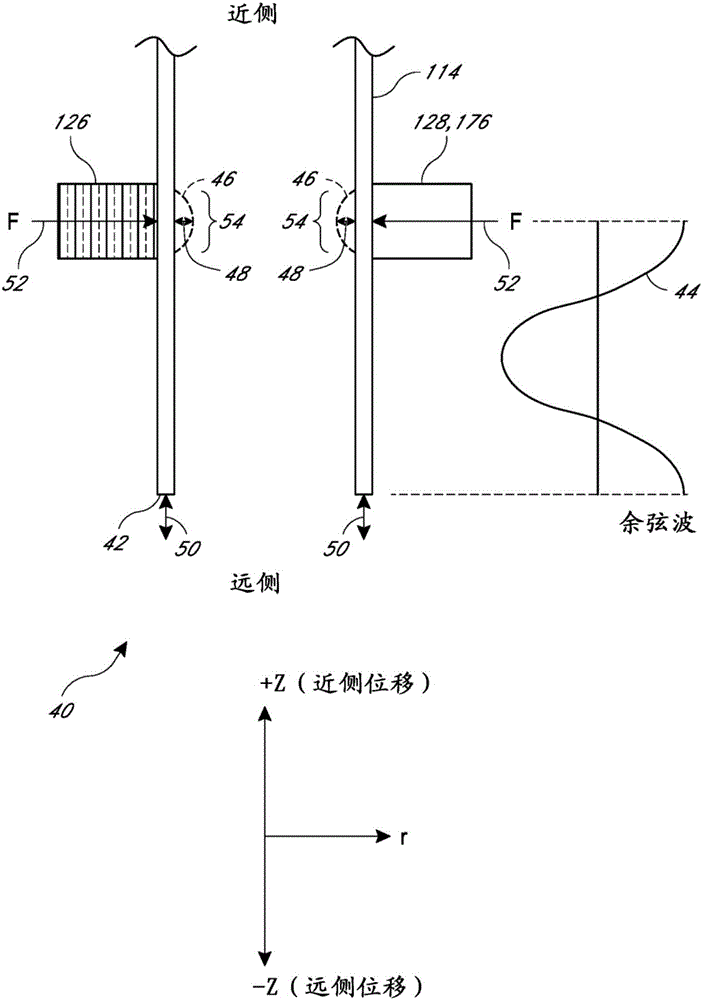

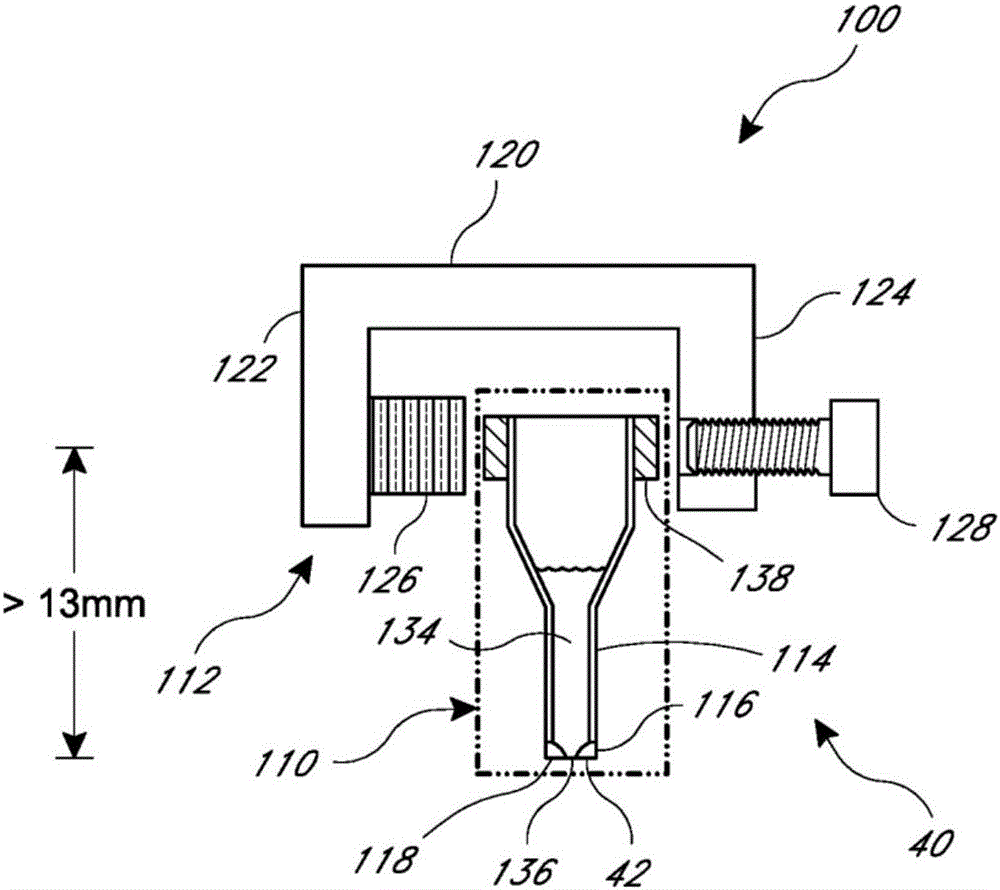

[0119] Embodiments described herein relate generally to systems and methods for acquiring and non-contactingly dispensing predetermined volumes of liquid, and in particular to acquiring and dispensing volumes of liquid—particularly but not exclusively for use in Dispensing and delivering small volumes of fluids such as for the automated production of DNA arrays or multiplexing assays—unique piezoelectric dispensing devices in which the liquid is dispensed in the form of individual droplets having volumes of, for example, on the order of picoliters to nanoliters drop. Embodiments of the dispensing device advantageously utilize disposable, detachable or detachable capillary assemblies while desirably maintaining the piezoelectric actuator or transducer further for subsequent use, thereby reducing the potential for cross-contamination of fluids and provide an economical and cost-effective method of reusing piezoelectric actuators or transducers for further manipulations such as d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com